@RustyRatRod thats what I figured I would have to do, its adjusted to what the tf2 kit says. It would probably be wise to pressure test it again as well, we did when we rebuilt it. Ill remove it when I put in the new vb and new to me torque converter... buying a torque converter this week..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dartin for Divorce

- Thread starter DentalDart

- Start date

-

@Bodyperson what does steering column collapsed mean?

I wonder what's up with it then? Sounds like you had a handle on it, but it's just not panning out. I hope you find it.@RustyRatRod thats what I figured I would have to do, its adjusted to what the tf2 kit says. It would probably be wise to pressure test it again as well, we did when we rebuilt it. Ill remove it when I put in the new vb and new to me torque converter... buying a torque converter this week..

View attachment 1715896816

They are designed to collapse in a collision. Not sure what year that design went into affect. The column is like a metal netting kinda like expanded metal so it will collapse and not get forced into the driver in a hard collision.@Bodyperson what does steering column collapsed mean?

@RustyRatRod yeah, I'm not too sure what happened, probably the vb? The only part I didn't install was the optional shift commnd feture, that was the governor valve machining to downshift at any speed. Machine shops were closed in Vegas during the beginning parts of covid shut down when Tony helped me rebuild the transmission. Right now the transmission gets about a 300ish RPM flare up between 2nd and 3rd. If it still does it with the new torque converter and valve body I'll have to assume I really really really suck at adjusting the KD cable...

mopowers

Well-Known Member

They are designed to collapse in a collision. Not sure what year that design went into affect. The column is like a metal netting kinda like expanded metal so it will collapse and not get forced into the driver in a hard collision.

It may not be the whole column that's collapsed. Could be just the steering shaft from someone being rough with installation or something. Either way, it needs to be corrected. There's no way I'd drive one of these old Mopars with half the coupler shoes hanging out of the coupler body.

@mopowers Coupler shoes no longer hanging out of the body. A very large wrench pushed it all back together. Thanks for pointing it out.

Ok. Messed with the car some more. Initial timing at 16.5 car seems moat happy here. New torque converter will be here soon! Its a 10 inch tight 3500-4k stall. I got it from GTX John here on FABO. he just took it out of his pink valiant that ran 11.31 and won the street car class at MATS. The only big difference between our cars is I have 3.23 gears and he has 3.91s. He said it would be really good for my car and how it is currently set up.

Lookin good. Now I just need a new trans pan with a drain plug.

72Dart6pack

Harder Better Faster Stronger.

I wish you well with that converter on the street.

His kids will love the launches !I wish you well with that converter on the street.

@72Dart6pack Thanks. Its going to be fun! When I emailed ptc they advised a tight 3-4k stall 9.5in converter for my combo..

@dadsbee yes they will! These kids love "going fast" and having lots of fun driving in the purple dart.

Mine has a 2800 in it and I wonder if it's going to move sometimes...

Well it was nice outside today. So I built some wheel cribs. Took the transmission out and went for a swim... made a dumb mistake... which is par for the course when a dumb *** like me is working on the Dart... tonight when wife and kids are in bed I'll clean it up and get the transmission cleaned and ready for reinstall tomorrow. My wife said no more taking the dart apart.... ever... so ummm... she is going to be pissed when I get a new rear end... and apparently I will really have to build a new motor outside of the car.. or I'll just have ti get another one that is already taken apart.

Oh. Also is my dip stick down far enough? Or is it to short? For accurate fluid measurements?

Oh. Also is my dip stick down far enough? Or is it to short? For accurate fluid measurements?

72Dart6pack

Harder Better Faster Stronger.

Your wife says your dip stick is kinda short.

Your wife says your dip stick is kinda short.

I know. But what about the dip stick in my transmission? Lol

This thing is pissing me off. I feel like none of the bell housing bolts want to freaking thread. Half the time I am just fighting getting a bolt to start.

So right now I want to burn it up, take my insurance check and buy one already done. I just want to get to drive the car.

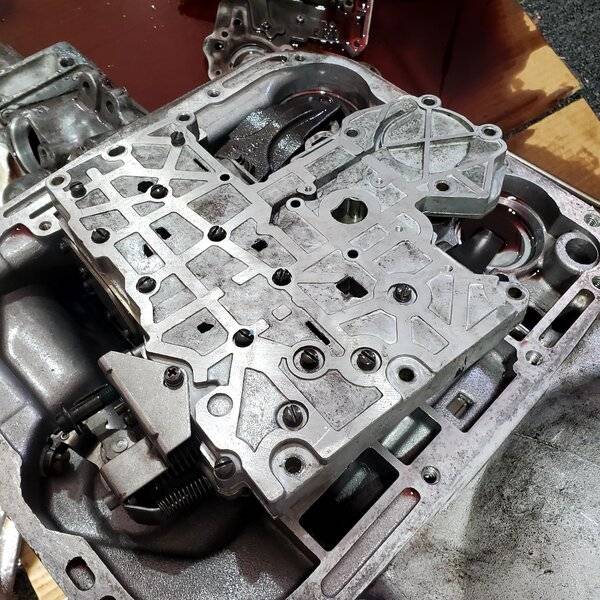

@RustyRatRod earlier you said allen head adjustment bolt, were you talking about the one on the VB? I wasnt going to adjust this VB because its a new turbo action vb but I also didnt build it. Should I check it? I also re-adjusted the front snd rear band and will double check them before final torquing the vb and pan on.

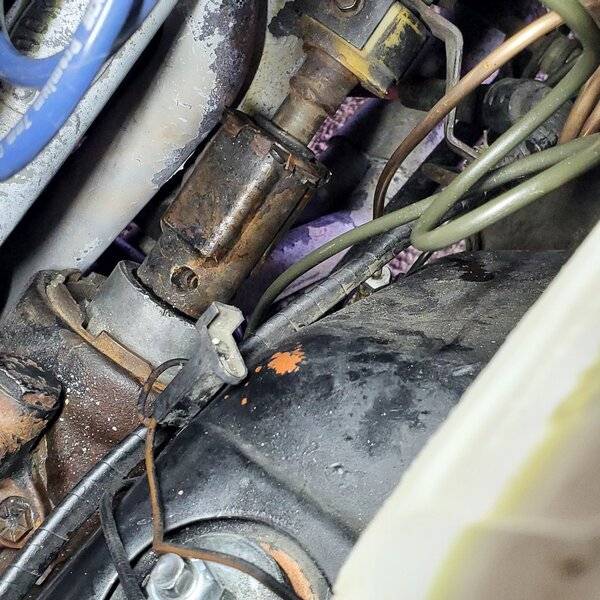

Oh I also got some matching spark plug wires. These wires 5 and 7 have 90 degree spark plug boots and go under the headers.

So right now I want to burn it up, take my insurance check and buy one already done. I just want to get to drive the car.

@RustyRatRod earlier you said allen head adjustment bolt, were you talking about the one on the VB? I wasnt going to adjust this VB because its a new turbo action vb but I also didnt build it. Should I check it? I also re-adjusted the front snd rear band and will double check them before final torquing the vb and pan on.

Oh I also got some matching spark plug wires. These wires 5 and 7 have 90 degree spark plug boots and go under the headers.

Phreakish

Well-Known Member

This thing is pissing me off. I feel like none of the bell housing bolts want to freaking thread. Half the time I am just fighting getting a bolt to start.

So right now I want to burn it up, take my insurance check and buy one already done. I just want to get to drive the car.

@RustyRatRod earlier you said allen head adjustment bolt, were you talking about the one on the VB? I wasnt going to adjust this VB because its a new turbo action vb but I also didnt build it. Should I check it? I also re-adjusted the front snd rear band and will double check them before final torquing the vb and pan on.

Oh I also got some matching spark plug wires. These wires 5 and 7 have 90 degree spark plug boots and go under the headers.

View attachment 1715908552

View attachment 1715908553

View attachment 1715908554

If the torque converter isn't fully seated, you'll play hell getting things aligned.

If it is fully seated, the trans should push flush up to the engine and you should still have a slight gap between the converter and the flex plate. Don't force it together or rely on the bolts to pull it together!

Once the trans is against the block and you're sure the dowels are aligned, the bolts should start pretty easily.

If the torque converter isn't fully seated, you'll play hell getting things aligned.

If it is fully seated, the trans should push flush up to the engine and you should still have a slight gap between the converter and the flex plate. Don't force it together or rely on the bolts to pull it together!

Once the trans is against the block and you're sure the dowels are aligned, the bolts should start pretty easily.

Its all in and aligned. Just the top bolt is a pain in the butt to get started and to tighten. Then i keep forgetting qhich bolts go where so I take them all in and out. Bleh. I keep threading bolts in the spare 727 to try and figure it out.

The VB didnt even want to go in the other day. So frustrating.

Last edited:

4spdragtop

Well-Known Member

Turn them each in only a couple turns until they're all in. That leaves a little "slop" so to speak.

Make sure the convertor is seated and spins freely before bolting to flex plate.

There should be fore and aft movement.

There should be fore and aft movement.

72Dart6pack

Harder Better Faster Stronger.

Is that a hole in the Bellhousing?

sireland67

Well-Known Member

Its for timing marks on a van.Is that a hole in the Bellhousing?

72Dart6pack

Harder Better Faster Stronger.

I'm calling BS on that.Its for timing marks on a van.

-

Similar threads

- Replies

- 0

- Views

- 375

- Replies

- 36

- Views

- 1K