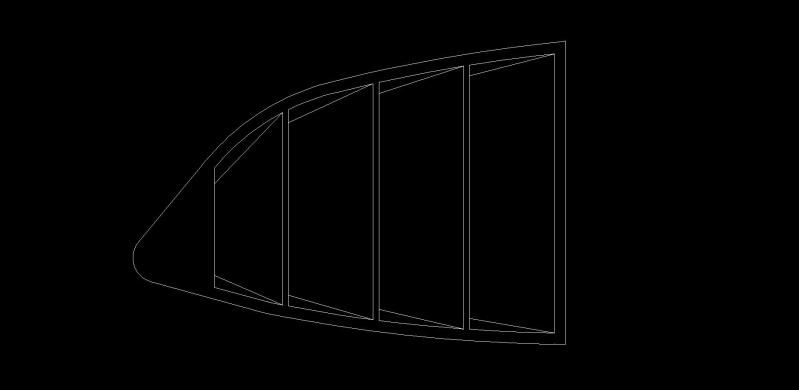

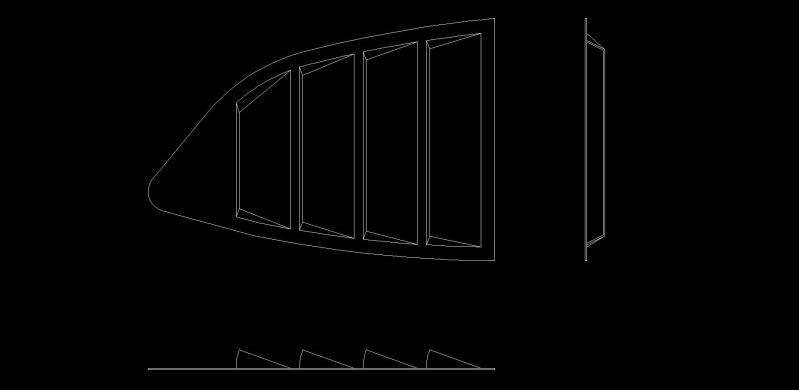

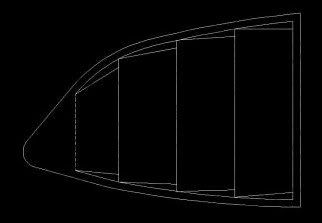

*reads about window curvature*

Well that's just f'ing /lame/.

Perhaps a thick seal that goes between the louvers and the glass could help correct that? or not?

EDIT: Out of curiosity, what was your planned construction process for this? I was designing with the idea that you'd take a flat sheet, the shape of the window, cut three sides around the louvers, bend that piece of metal up to make the slat, and then add the pieces on the sides to close them off. I am not very experienced in metal work, so if that's way off, forgive me. Doesn't seem like that small amount of welding would be too bad.

Alternatively, could cut the flat piece, bend the slats up, then put a single layer of fiberglass over the top maybe? cutting out the excess and allowing it to fill the gaps on the sides? Just a thought. I'm just spitballing to try to keep hope alive D: