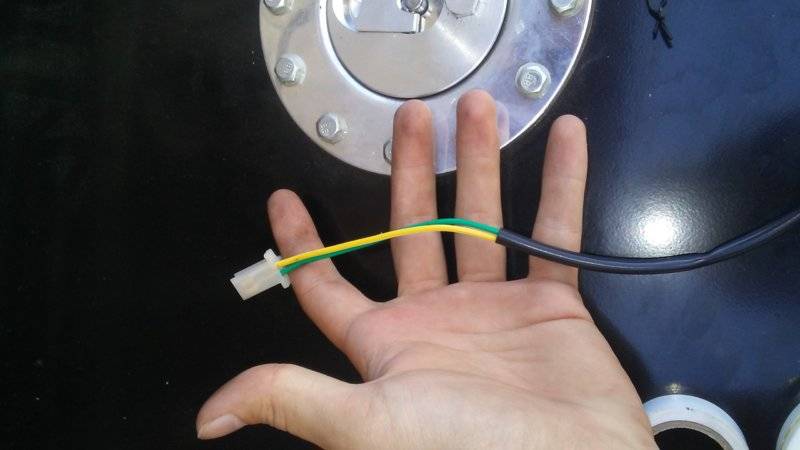

One wire on the fuel cell is a ground, the other is the power.

Im assuming the blue (and only wire) is the original gas gauge's/power, because theres a metal clip at the end by where the original fuel rail is that was the original ground...

Im checking resistance here shortly.

It's not exactly "power" so to speak. The factory gauge works a little bit like an ohmeter---it is measuring the resistance of the sender which varies with the arm position.. The functional path of the originial gauge is: Ignition switch...........to the cluster PC board........through the instrument voltage limiter (regulator).......to one stud of the gauge..........through the gauge and out the other stud.........through the harness back to the rear to the sender connection.....through the resistance of the sender.........and to ground

Without knowing "what that is" in your cell, it's a crap shoot. Why can't you get destructions? Is it used? You been to the manufacturer's website? Again, if it follows "GM" resistance, there is no way it will work with Mopar gauge.

If you can't find instructions, see if you can reach in the cell with a wire and manipulate the sender float.......or just turn the tank upside down to move it!!

Measure the resistance between the two connector terminals, and also from EACH of them to the tank ground. See if you can get a resistance change from empty to full

Here are the "general" Mopar resistances:

This is a gauge tester that someone kindly added the resistance values to:

About 74 ohms should cause the dash gauge to rest at empty

About 23 ohms should cause 1/2 gauge reading, and

About 10 ohms should cause the gauge to go to "full"