rmchrgr

Skate And Destroy

For the last couple days, I have been agonizing over how to run the fuel line in my Duster. Every method I have come up with has some major flaw whether it's too close to something it shouldn't be, is diffricult to execute cleanly or may open a different can of worms.

Right now, the cleanest solution appears to be having a short piece of hose from the outer bulkhead through the back of the passenger-side front wheel well and then through the inner fender panel. Right angle hose ends will keep it fairly neat. I considered a hard line with gravel guard here but the tight bends and fittings would make it stick out even further than the hose. I am looking at spiral hose covers to protect the hose from road debris but have not found anything specific yet.

The woven hose in this pic is an older piece that just happened to have a 90º hose end on it so it was used to demonstrate the idea. I'd make a new line as described below with more robust Aeroquip -6 AN socketless hose.

This is how it would come through the inner fender on the other side. From here it would route up the inner fender to the throttle body.

Guess my question is whether it will be safe to have this small length of line running behind the tire like this. On a dedicated race car sure, but this car will be street driven. I don't have the suspension in yet so I held up the wheel and tire to estimate where it would sit. (15 x 3.5" wheel with a 26" tire) It might be pretty close on the back end on full lock but it's hard to tell accurately. This would be the easiest method to execute cleanly but again, the major flaw could be having the line get damaged by road debris.

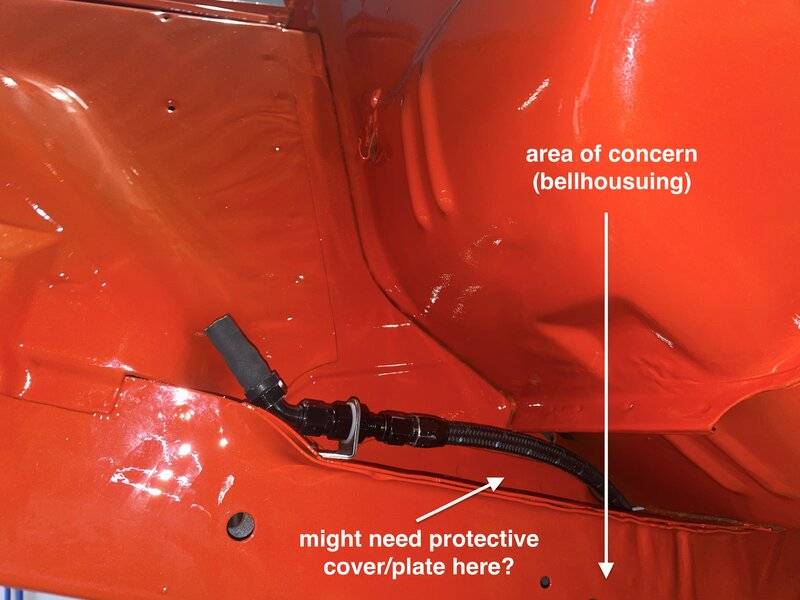

The other consideration is snaking the line through the space between the bottom of the firewall and the frame rail. The drawback here is that the hose is exposed right where it's supposed to be protected (converter ring gear). I can bolt a length of 1/8" plate to the area to protect the hose but that seems cumbersome. Maybe not though?

May not need the coupler in the middle there, this is just for mockup.

Right now, my inclination is to go through the fender well. What do you all think?

Thanks for any input.

- Greg

Right now, the cleanest solution appears to be having a short piece of hose from the outer bulkhead through the back of the passenger-side front wheel well and then through the inner fender panel. Right angle hose ends will keep it fairly neat. I considered a hard line with gravel guard here but the tight bends and fittings would make it stick out even further than the hose. I am looking at spiral hose covers to protect the hose from road debris but have not found anything specific yet.

The woven hose in this pic is an older piece that just happened to have a 90º hose end on it so it was used to demonstrate the idea. I'd make a new line as described below with more robust Aeroquip -6 AN socketless hose.

This is how it would come through the inner fender on the other side. From here it would route up the inner fender to the throttle body.

Guess my question is whether it will be safe to have this small length of line running behind the tire like this. On a dedicated race car sure, but this car will be street driven. I don't have the suspension in yet so I held up the wheel and tire to estimate where it would sit. (15 x 3.5" wheel with a 26" tire) It might be pretty close on the back end on full lock but it's hard to tell accurately. This would be the easiest method to execute cleanly but again, the major flaw could be having the line get damaged by road debris.

The other consideration is snaking the line through the space between the bottom of the firewall and the frame rail. The drawback here is that the hose is exposed right where it's supposed to be protected (converter ring gear). I can bolt a length of 1/8" plate to the area to protect the hose but that seems cumbersome. Maybe not though?

May not need the coupler in the middle there, this is just for mockup.

Right now, my inclination is to go through the fender well. What do you all think?

Thanks for any input.

- Greg