1/16/24:

I am continuing to slowly get items completed on the project.

Over the weekend we took a snowy jaunt up north to retrieve a proper A Body 8 3/4" Rear axle. It's not complete, yet I have all of the parts to make it so.

Lots of abrasive blasting and painting..... this is a blast.

Saving the Semi original/old Wheel Cylinders - They are made in the USA. A little honing and some blasting, and a quick coat of paint cleaned them right up!

Found Some Spare drums in my parts stash.. They cleaned up nicely.

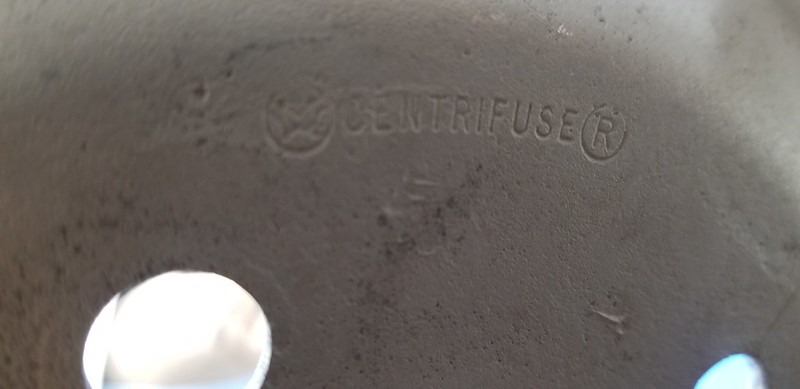

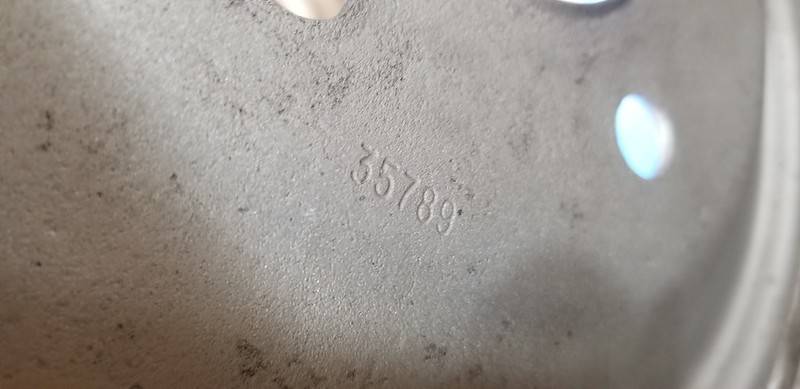

Interesting markings:

Degreased backing plates from the donor axle:

I do need to sort out / weld / level the shoe pads on these.

Cleaned up nicely.

In the "Paint Booth"

I am continuing to slowly get items completed on the project.

Over the weekend we took a snowy jaunt up north to retrieve a proper A Body 8 3/4" Rear axle. It's not complete, yet I have all of the parts to make it so.

Lots of abrasive blasting and painting..... this is a blast.

Saving the Semi original/old Wheel Cylinders - They are made in the USA. A little honing and some blasting, and a quick coat of paint cleaned them right up!

Found Some Spare drums in my parts stash.. They cleaned up nicely.

Interesting markings:

Degreased backing plates from the donor axle:

I do need to sort out / weld / level the shoe pads on these.

Cleaned up nicely.

In the "Paint Booth"