Last edited:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HELP!!! Is this suspension safe?!

- Thread starter Huron33

- Start date

-

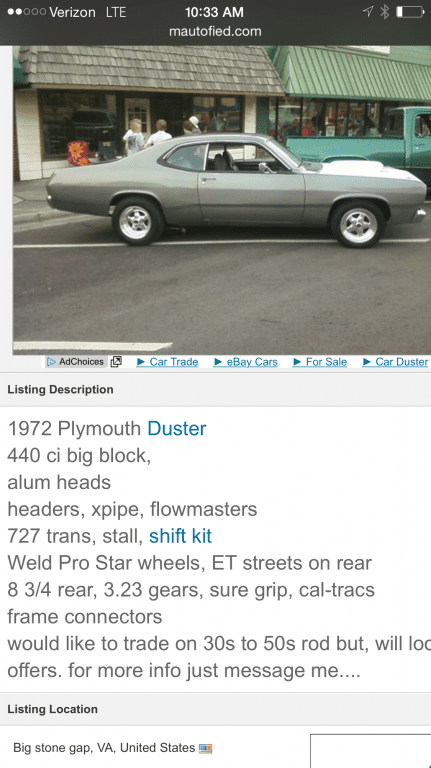

You have prolly seen this car online for sale and man who ever did the fabrication on this thing was a hack. I'm in the middle on welding patch panels and restoring this thing and I noticed this. Here's a pick of the car be fire I started

Those are Cal Tracs. They are a traction device for leaf spring cars. They work pretty dang good.

I stated above they are Caltracs.Those are Cal Tracs. They are a traction device for leaf spring cars. They work pretty dang good.

So that bolt that doesn't bolt to anything is how caltracs work?

I stated above they are Caltracs.

So that bolt that doesn't bolt to anything is how caltracs work?

It holds the bracket together. Yes, that's how it is designed.

The "extra frame rail" was added as part of the mini-tub. Your pictures don't show everything, but from what I can see it looks like it was done decently well. If you look at the 3" spring relocation kits out there you'll see there's nothing really crazy going on with the installation on your car.

Mopar-Man

Big Block Better Burnout

Looks like **** work to me!

Looks like **** work to me!

Based on what? You can't really see the quality of the welds in his pictures. Spray some random undercoat and let things surface rust a bit and everything looks like crap. Yeah, the tubing added to the frame wasn't cut back to be flush with the frame, but so what? Doesn't hurt anything as long as it doesn't interfere with the caltracs.

Mopar-Man

Big Block Better Burnout

Okay, I see what he did now. The reason the new spring pocket doesn't like up with the existing frame rail is because he lengthened the wheelbase by one inch for tire clearance.

Just odd how the metal in the frame rail was cut around the bolt location. I've built a few rides before so it looks suspicious.Okay, I see what he did now. The reason the new spring pocket doesn't like up with the existing frame rail is because he lengthened the wheelbase by one inch for tire clearance.

Cut flanged and fitted ready to stitch it up.

Well **** man, if you don't like it, take it off and send it to me. I'll take it.

Lol na im gonna take care of biz! Just some odd looking fab work.Well **** man, if you don't like it, take it off and send it to me. I'll take it.

famous bob

mopar misfit

they look like a home made cal trac imitation to me. they sure don`t look like mine !!Lol na im gonna take care of biz! Just some odd looking fab work.

Just odd how the metal in the frame rail was cut around the bolt location. I've built a few rides before so it looks suspicious.

Cut flanged and fitted ready to stitch it up.

View attachment 1715038902

View attachment 1715038903

The frame box was cut around the bolt for clearance because of the way the box was installed. Instead of sliding the box all the way into the original frame rail up to the subframe it was left further back to move the axle back. That centers the rear axle in the wheel tubs so taller tires can be used. The result is that the spring box sticks out, and had to be trimmed for clearance. It's probably also a home made spring box, but all the spring box really is in the relocation kits is a piece of square tubing. Compared to the Mopar performance kit there's nothing you couldn't build easily at home. The US Cartool kit is better quality, but again, it wouldn't be hard to replicate. Just take some extra time and metal. The nicest thing about it is that it bolts to the original spring hanger mount so you don't have to worry as much about locating everything properly. But back to your car, there's no strength in the section that's trimmed, you could cut the entire box back so it's flush with the rail. Wouldn't hurt a thing as long as you didn't cut the welds holding it in place.

Your other choice would be to reinstall the spring box as it's supposed to be installed, sliding it forward into the rail up against the crossmember. But if you do that you'll have to shorten the driveshaft if you've got one that works with the current set up.

It may be a home built Caltrac set up, but I don't see any reason it wouldn't work the same. But I'm just going off the pictures. Maybe it's not as pretty, but it looks plenty functional.

Last edited:

looks like it is designed to articulate. when accelerating the free bolt will push down against the spring locking the traction bar and limiting twist, any other time it will be free to move. the reason for this is to stop rear steer as the wheels ride bumps and dips in the road with the traction bar pulling at the axle. rear steer can be exaggerated with traction bars at different ride heights as to whether the fuel tank is full or empty, trunk full of stuff etc.

you could put a rubber sleeve on that bolt to stop it clacking against the spring when you hit the throttle.

you could put a rubber sleeve on that bolt to stop it clacking against the spring when you hit the throttle.

Thanks for the thorough respond 73BluNblu and Bozwel So in your opinion it is safe? Or do what 72bluNblu suggested.looks like it is designed to articulate. when accelerating the free bolt will push down against the spring locking the traction bar and limiting twist, any other time it will be free to move. the reason for this is to stop rear steer as the wheels ride bumps and dips in the road with the traction bar pulling at the axle. rear steer can be exaggerated with traction bars at different ride heights as to whether the fuel tank is full or empty, trunk full of stuff etc.

you could put a rubber sleeve on that bolt to stop it clacking against the spring when you hit the throttle.

Thanks for the thorough respond 73BluNblu and Bozwel So in your opinion it is safe? Or do what 72bluNblu suggested.

looks fine to me. i'd run with it.

the only issue I can see is the pivot bolt (leaf spring bolt) cannot be done up tight otherwise it'll stop the unit articulating.

as that bolt can only be lightly tightened it'll need a Nyloc nut or two nuts locked together to hold in place. unfortunately it'll allow the leaf spring bush to rotate slightly. If that is a rubber bush in there change it for nylon top hat bushes that are a perfect fit. it'll have less flex but allow radial movement, plus it will act as an antiroll bar limiting the amount the leaf springs can twist on cornering.

I may copy that design for the rear of my Barracuda.

I think it's safe, but that's just my opinion based on a few pictures on the internet. I don't know if it's set up properly for your car or if it's working as it should be. But based on what I can see I don't think it's unsafe, the springs aren't going to fall off the car or anything.

famous bob

mopar misfit

that's an idea that might be worth thinkin about. but their supposed to be preloaded a certain amount when right.looks like it is designed to articulate. when accelerating the free bolt will push down against the spring locking the traction bar and limiting twist, any other time it will be free to move. the reason for this is to stop rear steer as the wheels ride bumps and dips in the road with the traction bar pulling at the axle. rear steer can be exaggerated with traction bars at different ride heights as to whether the fuel tank is full or empty, trunk full of stuff etc.

you could put a rubber sleeve on that bolt to stop it clacking against the spring when you hit the throttle.

-

Similar threads

- Replies

- 19

- Views

- 1K

- Replies

- 0

- Views

- 350

- Replies

- 30

- Views

- 917

- Replies

- 10

- Views

- 799