You don't want to immerse the horns in any liquid.

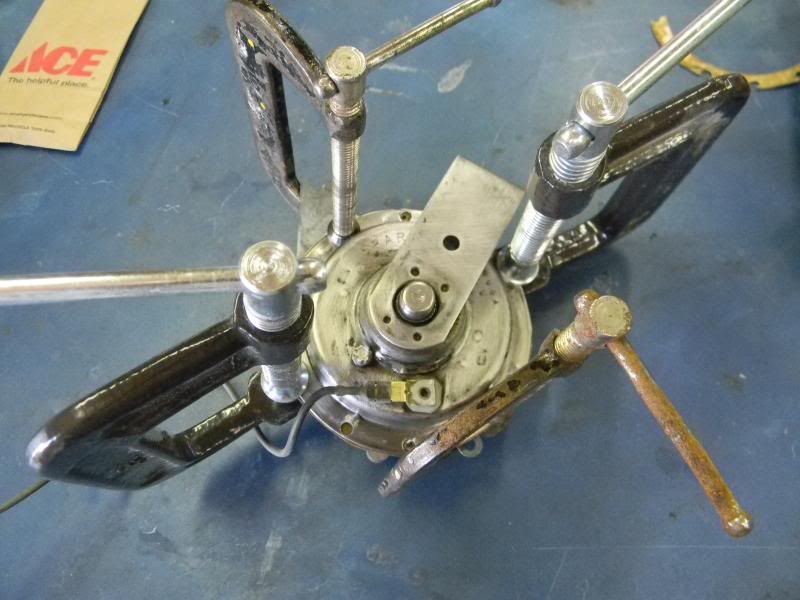

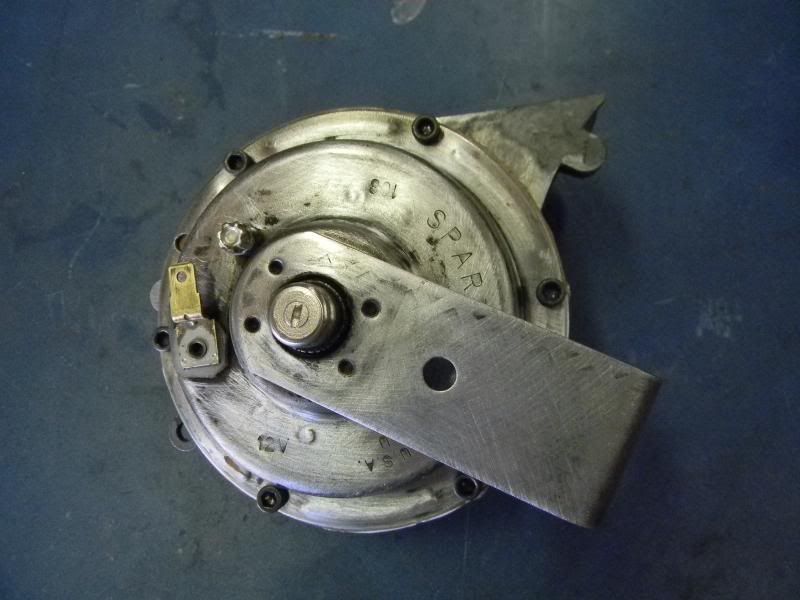

Horns work just like a buzzer. They are in fact sort of a modified relay. What you have in there is an electrical magnet in series with a normally closed ELECTRICAL CONTACT.

When power is applied the armature of the "relay" (buzzer) is pulled down by magnetism against the core of the electromagnet. As the armature is pulled down, it itself opens the electrical contact, breaking the current path, and stopping the magnetic pull. Either a separate spring, or the spring action of the horn diaphragm mechanically pulls the armature back up the other way, back to it's starting place, the electrical contact closes, and "things happen" all over again, over and over.

Meanwhile, the armature is mechanically attached to the horn diaphragm, which amplifies the noise of the buzzer, and the resonance of the cavity of the housing causes the trumpet sound, so to speak

Normally there is an adjustment screw which actually moves one of the contacts to control tone

So what you have in there is electrical wiring, mechanical movement, and electrical contacts, all of which may be damaged by solvents or corroded from liquids

http://www.cvel.clemson.edu/auto/actuators/horns.html

http://en.wikipedia.org/wiki/File:Car_horn_in_use-tag.svg