Just got back from Silver lake Sand dunes where my jeep ran 220+ if I were beating on it.

Been fighting this heat issue for years. Its a mild built mopar 360 with cast heads, around 10:1 compression, flat top pistons, cam, headers.

The water pump is a mopar performance and i think its the 6 blade so it says its made for drag race use...could this be my issue??

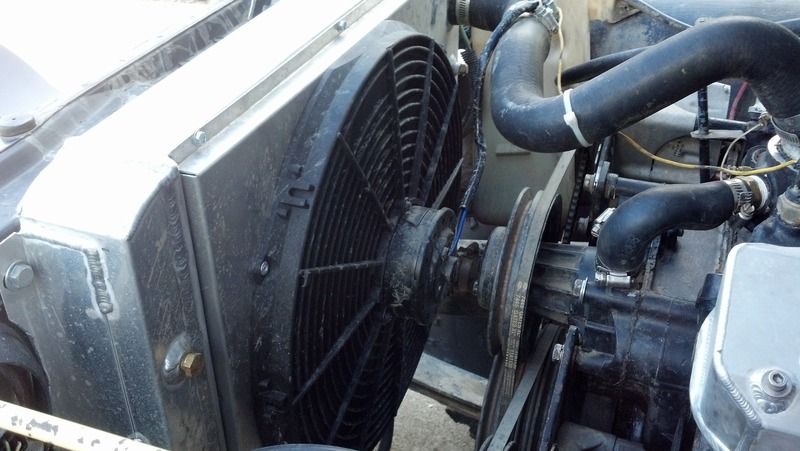

The radiator is aluminum with a electric fan and a shroud that covers the entire rad. The shop that built it says its good for 600hp and they put it on the jeeps with the Hemi conversions.

I changed the cap thinking it may be leaking. The stat is 180* and I even pulled it thinking it was sticking and ran a restriction plate. Still no change. Running down the road it will run at 195*.

Should i put on a stock pump? could the coolant be caviatating at the high RPM? Weld a plate to the back of a stock pump? or a plate on the back of the performance drag racing only pump?

My hood gets so hot you cannot touch it. So i'm also wondering if its just heat soaking? I have header wrap on the way. Also, the heater bypass hose is still connected...should I block it off and drill holes in the stat?

thanks!

Been fighting this heat issue for years. Its a mild built mopar 360 with cast heads, around 10:1 compression, flat top pistons, cam, headers.

The water pump is a mopar performance and i think its the 6 blade so it says its made for drag race use...could this be my issue??

The radiator is aluminum with a electric fan and a shroud that covers the entire rad. The shop that built it says its good for 600hp and they put it on the jeeps with the Hemi conversions.

I changed the cap thinking it may be leaking. The stat is 180* and I even pulled it thinking it was sticking and ran a restriction plate. Still no change. Running down the road it will run at 195*.

Should i put on a stock pump? could the coolant be caviatating at the high RPM? Weld a plate to the back of a stock pump? or a plate on the back of the performance drag racing only pump?

My hood gets so hot you cannot touch it. So i'm also wondering if its just heat soaking? I have header wrap on the way. Also, the heater bypass hose is still connected...should I block it off and drill holes in the stat?

thanks!