I do have one, doesn't go empty or less than full while running. Has a new fuel pump before I got it.It would be nice if you were running a see through fuel filter, and see if it goes empty when the symptoms start.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hot Start Issue Choke stuck?

- Thread starter bisblue

- Start date

-

Mattax

Just the facts, ma'am

"I did and timed it about 5 degrees advanced. It's hard to get it up to temp and idling at 750 to time it"

So it was at 5* BTDC when running on fast idle? maybe 1200 rpm?

That's probably not enough. Depending on the advance curve, 5* at fast idle might be 0* at a couple 100 rpm down. Give it some more advance. Try 10* at the same speed. You can back off later as the pieces of the puzzle come together.

OSAC ?

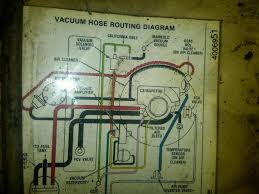

Its explained in the emmissions booklets you printed off for vacation.

1973 Imperial and Chrysler Clean Air System Reference Service Repair Book from the Master Technician's Service Conference (Session 302)

&

1973 Chrysler and Imperial Exhaust Emissions Book from the Master Technician's Service Conference (Session 308)

You'll need to hunt for the diagrams for your car. It should help ID and track down all of the vacuum ports and temperature valves.

If its not needed to pass emissions or restoration, I'd take the OSAC out of the picture permanently. When working, it trades of some efficiency and response for slightly better NOx under acceleration.

So it was at 5* BTDC when running on fast idle? maybe 1200 rpm?

That's probably not enough. Depending on the advance curve, 5* at fast idle might be 0* at a couple 100 rpm down. Give it some more advance. Try 10* at the same speed. You can back off later as the pieces of the puzzle come together.

OSAC ?

Its explained in the emmissions booklets you printed off for vacation.

1973 Imperial and Chrysler Clean Air System Reference Service Repair Book from the Master Technician's Service Conference (Session 302)

&

1973 Chrysler and Imperial Exhaust Emissions Book from the Master Technician's Service Conference (Session 308)

You'll need to hunt for the diagrams for your car. It should help ID and track down all of the vacuum ports and temperature valves.

If its not needed to pass emissions or restoration, I'd take the OSAC out of the picture permanently. When working, it trades of some efficiency and response for slightly better NOx under acceleration.

One does control the hot air flapper.One of these may control the hot air flapper in the air cleaner's snorkel.

There may be a second flapper, also vacuum controlled, that opens when the engine is running. This minimized vapor loss to atmosphere when the engine is off.

The best run I got I was able to time it around 750 before it died. Normally I can't see the timing mark when warming up cold around 1200. It was originally about 12 or so. It might be a bit more advanced than 5. I timed it by ear, just trying to trouble shoot today."I did and timed it about 5 degrees advanced. It's hard to get it up to temp and idling at 750 to time it"

So it was at 5* BTDC when running on fast idle? maybe 1200 rpm?

That's probably not enough. Depending on the advance curve, 5* at fast idle might be 0* at a couple 100 rpm down. Give it some more advance. Try 10* at the same speed. You can back off later as the pieces of the puzzle come together.

I'll check out the emmissions info. Hoping to go EFI, it's first on my wish list.

Gonna need exhaust first, the single on this thing is pretty worn out.

it does seem a little retarded, but I can't see how that would change that much from cold to hot.

Mattax

Just the facts, ma'am

maybe by original he meant 12* at 1200, and 5* @ 750. When he gets back we'll find out.it does seem a little retarded, but I can't see how that would change that much from cold to hot.

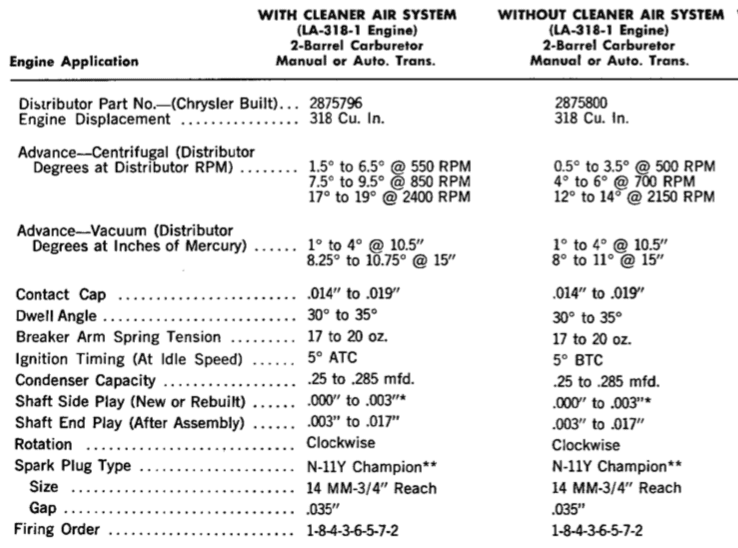

But if so that would be just below the low spec for a late 60s Plymouth CAP/CAS 318 2bbl. From 74 FSM when can get the factory specs - I'm assuming he's get a 74 FSM downloaded or purchased.

maybe by original he meant 12* at 1200, and 5* @ 750. When he gets back we'll find out.

But if so that would be just below the low spec for a late 60s Plymouth CAP/CAS 318 2bbl. From 74 FSM when can get the factory specs - I'm assuming he's get a 74 FSM downloaded or purchased.

Apologies I've only had one other carbureted vehicle, a C20, it didn't have timing marks in the right spot so I just timed it by ear, or was a one wire HEI set up.

A friend thought the timing was retarded so I thought it was retarded when it was actually advanced. The first timing attempt the mark was just barely visible at 750. I fiddled with it. I'd assume it is currently between 5-10 degrees. I just timed it by ear the last time I tried it.

I'm not sure it was fully warmed up when I timed it, I just put in a new thermostat. It was stalling out before it warmed up so I was pulling out my hair a bit.

So what do you fellas think is the best order of attack?

I was gonna plug most of the vacuum hose connections, and start working backwards. I've tried adjusting timing several ways and never noticed a big difference with this issue.

I was gonna plug most of the vacuum hose connections, and start working backwards. I've tried adjusting timing several ways and never noticed a big difference with this issue.

Mattax

Just the facts, ma'am

Well timing is pretty critical. In neutral you can keep advancing timing and the rpm will increase. The mistake people make when doing this (I was one of these people) is thinking timing should continue to be increased since the engine seems to run faster with more advance. The short version is there's hardly any load on the engine in neutral so the engine will speed up with lean mixture and lots of advance. But its not generating enough torque and power to be efficient when shifted into gear.So what do you fellas think is the best order of attack?

I was gonna plug most of the vacuum hose connections, and start working backwards. I've tried adjusting timing several ways and never noticed a big difference with this issue.

To your first question, order of attack.

1. Same as you're thinking. Cap or plug every vacuum connection not needed for initial tuning. This does mean identifying each item and/or system. I'd suggest colored electric tape or masking tape and marker on the hoses to keep track of what you're undoing. No caps? a golf tee or similar in the hose coming from the vacuum source works fine.

Not needed for initial tuning.

a. OSAC

b. EGR

c. Warm air from stove. (If it is working, its not a problem. But with the aircleaner off, its not doing anything)

d. vacuum advance (unless it says otherwise in the FSM or the underhood sticker, initial timing is set without vac advance)

e. any vacuum resevoir for cruise control etc.

Needed.

a. PCV valve attached and working.

b. Air door on snorkel if the air cleaner cover is on.

Optional.

Power brake booster. If you think its leaking, plug the line to it.

At some point you may want to borrow or buy a vacuum pump to test for leaks and trmperature control valve operations. But for now, hunting everything thing down and capping or plugging is all thats needed.

2. Check and clean spark plugs if fouled.

3. Reset timing

a. Look up the advance curve in the FSM. It will be in the back of the electrical section under ignition. Double the rpm and double the advance degrees. Add this to the base timing.*

b. Fire it up and after kicking it down to the normal fast idle, increase the advance 5* or so. Try to get it into the range based on (a)

4. Run the base idle screw in enough so the engine keeps running without having to keep pumping the pedal.

Then recheck timing at rpm, and readjust if its still lower than spec.

If its running on its own, even at 1000 or 1200 rpm, then see if the idle speed screw can be turned out slowing the engine a bit. Recheck timing.

Then see what happens turning idle mix screws in and out. Do they have any effect at all?

Keep repeating these steps to see if lowering the idle speed with the throttle position screw is possible.

I'm sure if I was there I'd being some other thi ngs too, such as checking the squirters depending on how things are going and what the eyes ears and nose suggest.

Mattax

Just the facts, ma'am

3a*

The advance specs will look like this. Here's the section from a '69 FSM from posted by stumblinghorse. '74 is probably different. The only question is how much different.

To figure advance on the engine.

1.5* @ 550 rpm = 3* @ 1100 rpm crankshaft speed. minimum

6.5* @ 550 rpm = 13* @ 1100 engine rpm. maximum

So we can see there is a pretty big increase in timing from the initial to 1100 rpm, as much as 13*.

The rpm of the initial timing is in the Fuel section of the '69 FSM, but generally its around 650 - 700 rpm.

By '75, it was also on a sticker someplace in the engine compartment. So you may find it there in your '74.

When dealing with a factory CAS setup that uses retarded initial timing, especially with hacked up emissions systems, I would experiment with more initial, at least to get it running.

The non-CAS 318 provides some guidance for a what more normal timing and advance would be. Starting around 5* BTC at maybe 700 rpm, it would then advance 1* to 7* by 1000 rpm. This means the timing at 1000 rpm would be 6 to 12*.

Use this to estimate if the timing is in acceptable range when you can't get the engine speed slow enough to establish initial.

The reason to keep checking the timing at different rpms is we don't know if the distributor is the original one.

The advance specs will look like this. Here's the section from a '69 FSM from posted by stumblinghorse. '74 is probably different. The only question is how much different.

To figure advance on the engine.

1.5* @ 550 rpm = 3* @ 1100 rpm crankshaft speed. minimum

6.5* @ 550 rpm = 13* @ 1100 engine rpm. maximum

So we can see there is a pretty big increase in timing from the initial to 1100 rpm, as much as 13*.

The rpm of the initial timing is in the Fuel section of the '69 FSM, but generally its around 650 - 700 rpm.

By '75, it was also on a sticker someplace in the engine compartment. So you may find it there in your '74.

When dealing with a factory CAS setup that uses retarded initial timing, especially with hacked up emissions systems, I would experiment with more initial, at least to get it running.

The non-CAS 318 provides some guidance for a what more normal timing and advance would be. Starting around 5* BTC at maybe 700 rpm, it would then advance 1* to 7* by 1000 rpm. This means the timing at 1000 rpm would be 6 to 12*.

Use this to estimate if the timing is in acceptable range when you can't get the engine speed slow enough to establish initial.

The reason to keep checking the timing at different rpms is we don't know if the distributor is the original one.

Last edited:

Distributor is new. Also alternator, ECU, fuel pump coil, ballast resistor, voltage regulator, starter... I replaced the VR and ECU.

I'm guessing they were chasing the same problem when they parked it a few years ago.

I'm guessing they were chasing the same problem when they parked it a few years ago.

OSAC ?

Its explained in the emmissions booklets you printed off for vacation.

1973 Imperial and Chrysler Clean Air System Reference Service Repair Book from the Master Technician's Service Conference (Session 302)

&

1973 Chrysler and Imperial Exhaust Emissions Book from the Master Technician's Service Conference (Session 308)

So is it worth bypassing the OSAC for troubleshooting, same with the EGR? Can you just run vacuum off the carb instead to the distributor? I was plugging the vacuum advance while timing.

Do OSAC valves wear out? I only saw some on ebay for sale and they were pricey.

Mattax

Just the facts, ma'am

???

See posts 52 Hot Start Issue Choke stuck?

and 59 Hot Start Issue Choke stuck?

I dont know what your car came with in terms of timing specs or emissions controls. Things changed every year, sometimes mid year. I told you what I could see in the photos and suggested where to look.

Find and post up the specs and info.

With that, we can help further with making in run decent, or return close to stock if thats your goal.

Without that its all generalities which is OK when hot rodding but not so much when dealing with carbs and timing etc made to work with specific equipment.

See posts 52 Hot Start Issue Choke stuck?

and 59 Hot Start Issue Choke stuck?

I dont know what your car came with in terms of timing specs or emissions controls. Things changed every year, sometimes mid year. I told you what I could see in the photos and suggested where to look.

Find and post up the specs and info.

With that, we can help further with making in run decent, or return close to stock if thats your goal.

Without that its all generalities which is OK when hot rodding but not so much when dealing with carbs and timing etc made to work with specific equipment.

I thought I added a picture, searched my phone and couldn't find where I took it. I believe it the sticker said TDC warm at 750, which I'm assuming was 0 degrees. It wouldn't run at that, had to be closer to 5-10 degrees so I timed it up.

I read the OSAC bulletins some good info, wasn't sure how important NoX emissions were for a cruiser with no SMOG requirement. I was curious if folks bypassing SMOG equipment needed a non SMOG carb to run well, or if you could tune it a bit and go without to simplify things are reduce the vacuum lines running everywhere.

I've got someone who is gonna take a picture and send it to me of the timing decal, I'll upload it when they do.

I read the OSAC bulletins some good info, wasn't sure how important NoX emissions were for a cruiser with no SMOG requirement. I was curious if folks bypassing SMOG equipment needed a non SMOG carb to run well, or if you could tune it a bit and go without to simplify things are reduce the vacuum lines running everywhere.

I've got someone who is gonna take a picture and send it to me of the timing decal, I'll upload it when they do.

Last edited:

FWIW in my opinion stock timing specs are out the window with our gas today. You gotta start the fire earlier to get a complete burn.

Copy,FWIW in my opinion stock timing specs are out the window with our gas today. You gotta start the fire earlier to get a complete burn.

Thanks again for all the help

Egr isnt bypassed unless you remove it and block it.

The will leak internally.

My ‘80 power wagon came factory with egr delete.

I have had my share of hair pulling over a crappy egr valve or egr gasket leaking.

Dont give up,you will find it.

The will leak internally.

My ‘80 power wagon came factory with egr delete.

I have had my share of hair pulling over a crappy egr valve or egr gasket leaking.

Dont give up,you will find it.

TDC=LOL. Absolutely not

Is there a good test for EGR function?Egr isnt bypassed unless you remove it and block it.

The will leak internally.

My ‘80 power wagon came factory with egr delete.

I have had my share of hair pulling over a crappy egr valve or egr gasket leaking.

Dont give up,you will find it.

I'm aware of TDC, but didn't see any timing specs on the engine bay decal. Just rpm and operating temp....TDC=LOL. Absolutely not

Remove it and put a 1/4” steel plate in its place.Is there a good test for EGR function?

I'm aware of TDC, but didn't see any timing specs on the engine bay decal. Just rpm and operating temp....

It looks like it says timing= TDCIs there a good test for EGR function?

I'm aware of TDC, but didn't see any timing specs on the engine bay decal. Just rpm and operating temp....

Mattax

Just the facts, ma'am

TJ. It depends on the EGR. You might be right. I was assuming its the type with the plunger valve in the passage and only opens when there's ported vacuum on it.Egr isnt bypassed unless you remove it and block it.

...Remove it and put a 1/4” steel plate in its place.

If its that type, then removing it may dilute the intake full time.

Another possibility. It wouldn't surprise me if this engine came with an external idle enrichment control.

So,

Got home last night and just had time to fiddle for a minute. I got a haynes manual with a vacuum diagram in the mail. Capped off everything, of course the PCV valve was a replacement but was brittle and broke. Same with the brake booster valve, it broke.

I capped everything and it ran worse than before.

Gonna go get all the size hoses and valves that broke and start replacing them, and trying to replicate the diagram routing. I tested the EGR with a hand vacuum pump, seemed to be working.

One question, I am not sure I'm seeing the Vacuum Solenoid Valve as seen in the diagram. There is a vacuum attached to one of the heater core lines. Just curious if it might be MIA

![IMG_20181125_204029361[1].jpg IMG_20181125_204029361[1].jpg](https://www.forabodiesonly.com/mopar/attachments/img_20181125_204029361-1-jpg.1715253757/)

Got home last night and just had time to fiddle for a minute. I got a haynes manual with a vacuum diagram in the mail. Capped off everything, of course the PCV valve was a replacement but was brittle and broke. Same with the brake booster valve, it broke.

I capped everything and it ran worse than before.

Gonna go get all the size hoses and valves that broke and start replacing them, and trying to replicate the diagram routing. I tested the EGR with a hand vacuum pump, seemed to be working.

One question, I am not sure I'm seeing the Vacuum Solenoid Valve as seen in the diagram. There is a vacuum attached to one of the heater core lines. Just curious if it might be MIA

Finally found that although I had spark when hot before, it started cutting out earlier and earlier. Tried a new coil and it's running great. Gonna try to time it and adjust air mix screws tonight.

Thanks again for the help folks.

Thanks again for the help folks.

-

Similar threads

- Replies

- 7

- Views

- 405