375inStroke

Well-Known Member

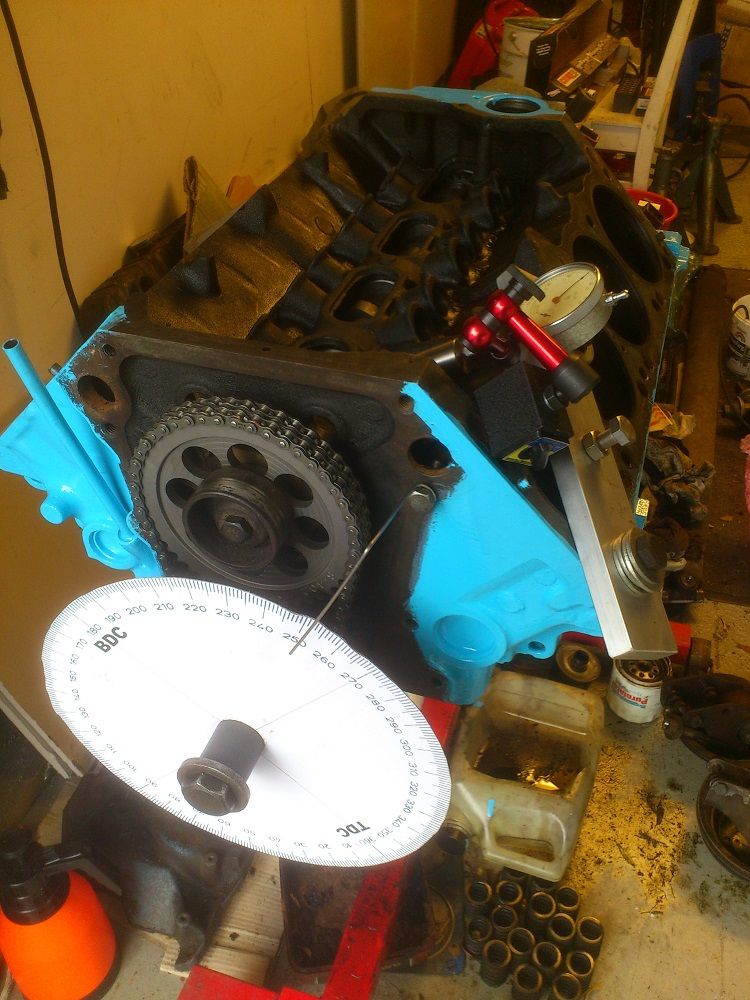

I printed one out on 11X17 paper after googling degree wheel and limiting to images over 1024 pixels, and glued it onto cardboard. No distortion, no money, and no problem. Finding exact TDC and lining up the wheel is probably the hardest part. There's a dial indicator here, but I actually bolted down a head and used a piston stop made from a spark plug to find TDC and measure the lifter movement.