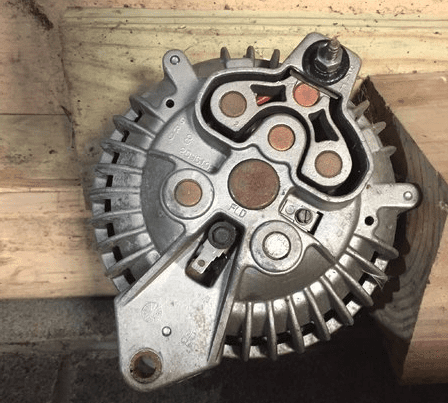

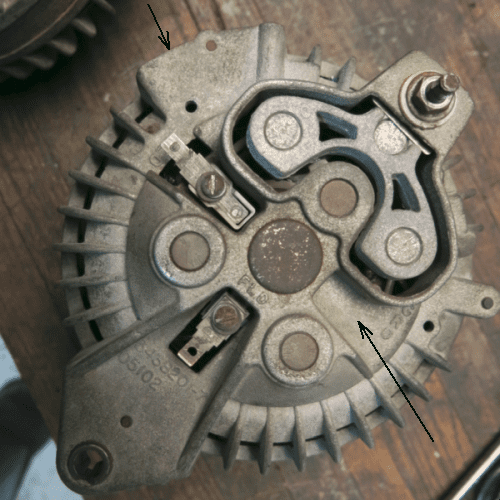

Roundback and Squareback refer to the style of housing.

Roundback through model year 1969.

Roundback for model years 1970-71 usually has a slightly different rear housing

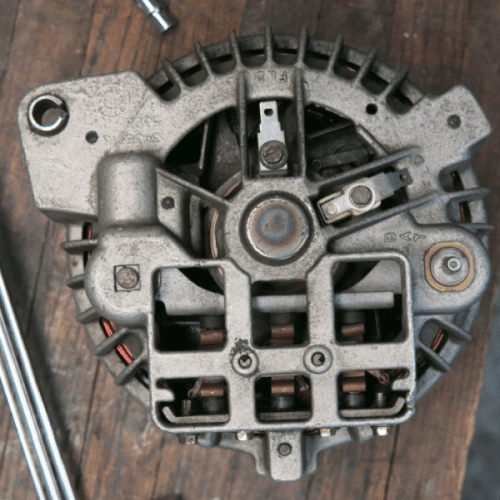

Squareback

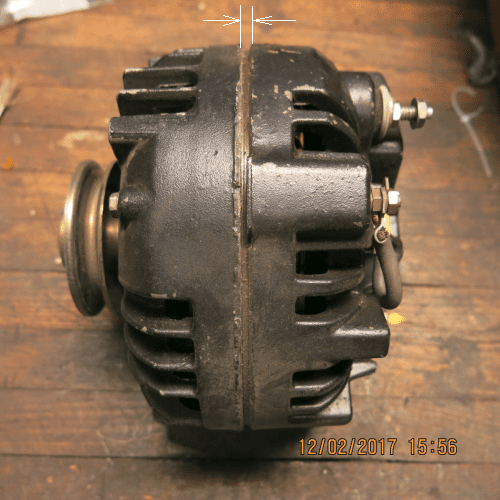

Revised Squareback

Is most easily differentiated by the thin middle between the housings.

Overall these are slightly bigger but can usually be made to fit in the same location as the earlier alternators.

THE STYLE OF CASTING CAN NOT BE RELIED ON TO MATCH THE WIRING WITH THE VOLTAGE REGULATOR

First lets look at identifying the two standard alternator connection types.

That will be followed by a link to a post by @67Dart273 illustrating some of the ways rebuilders chop up and change them.

Terms:

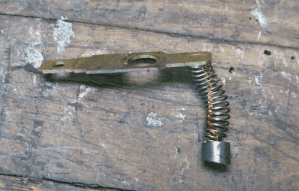

Brush is a spring loaded electrical contact made of carbon.

This is a brush assembly.

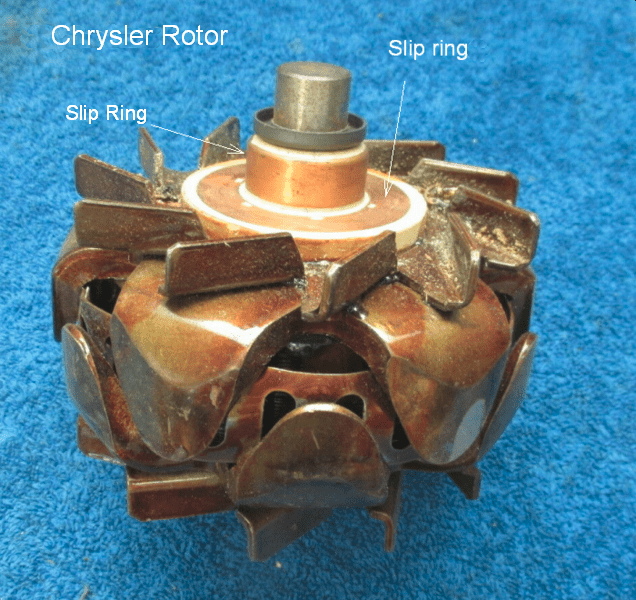

Slip ring is the spinning contact surface.

Field refers to the rotor's slip rings and electrical windings.

Field is short for the electromagnetic field created when electricity flows through those windings.

Functional Identification

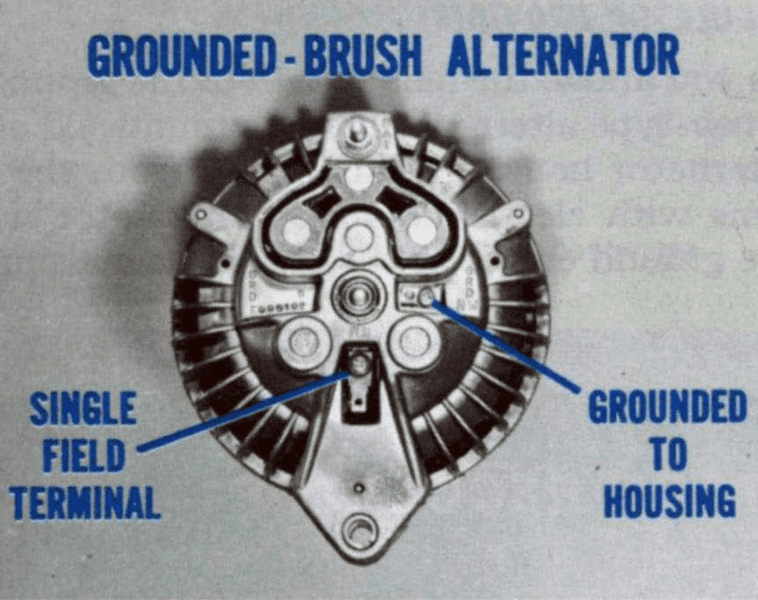

Grounded-brush Alternator

One brush assembly is grounded to the housing.

The other brush is insulated from ground and has a terminal.

This terminal gets connected to the output wire from the voltage regulator.

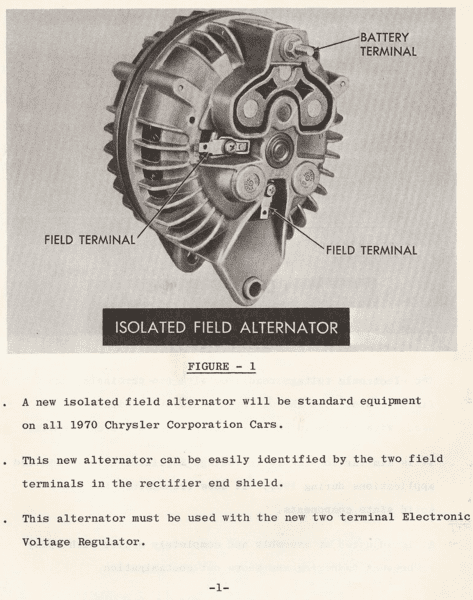

from The 1970 Alternator & Regulator (Session 269) from the Master Technician's Service Conference

Isolated-Field Alternator

Both brush assemblies are insulated from the housing and have connecting terminals.

Both terminals get connected to the voltage regulator.

from https://www.hamtramck-historical.com/images/serviceHighlights/70 sh 71.jpg

Roundback through model year 1969.

Roundback for model years 1970-71 usually has a slightly different rear housing

Squareback

Revised Squareback

Is most easily differentiated by the thin middle between the housings.

Overall these are slightly bigger but can usually be made to fit in the same location as the earlier alternators.

THE STYLE OF CASTING CAN NOT BE RELIED ON TO MATCH THE WIRING WITH THE VOLTAGE REGULATOR

First lets look at identifying the two standard alternator connection types.

That will be followed by a link to a post by @67Dart273 illustrating some of the ways rebuilders chop up and change them.

Terms:

Brush is a spring loaded electrical contact made of carbon.

This is a brush assembly.

Slip ring is the spinning contact surface.

Field refers to the rotor's slip rings and electrical windings.

Field is short for the electromagnetic field created when electricity flows through those windings.

Functional Identification

Grounded-brush Alternator

One brush assembly is grounded to the housing.

The other brush is insulated from ground and has a terminal.

This terminal gets connected to the output wire from the voltage regulator.

from The 1970 Alternator & Regulator (Session 269) from the Master Technician's Service Conference

Isolated-Field Alternator

Both brush assemblies are insulated from the housing and have connecting terminals.

Both terminals get connected to the voltage regulator.

from https://www.hamtramck-historical.com/images/serviceHighlights/70 sh 71.jpg

Last edited: