JoesEdge

Well-Known Member

Hey guys I wanted to share the work I did over the 4th of July and the work I did leading up to the 4th of July.

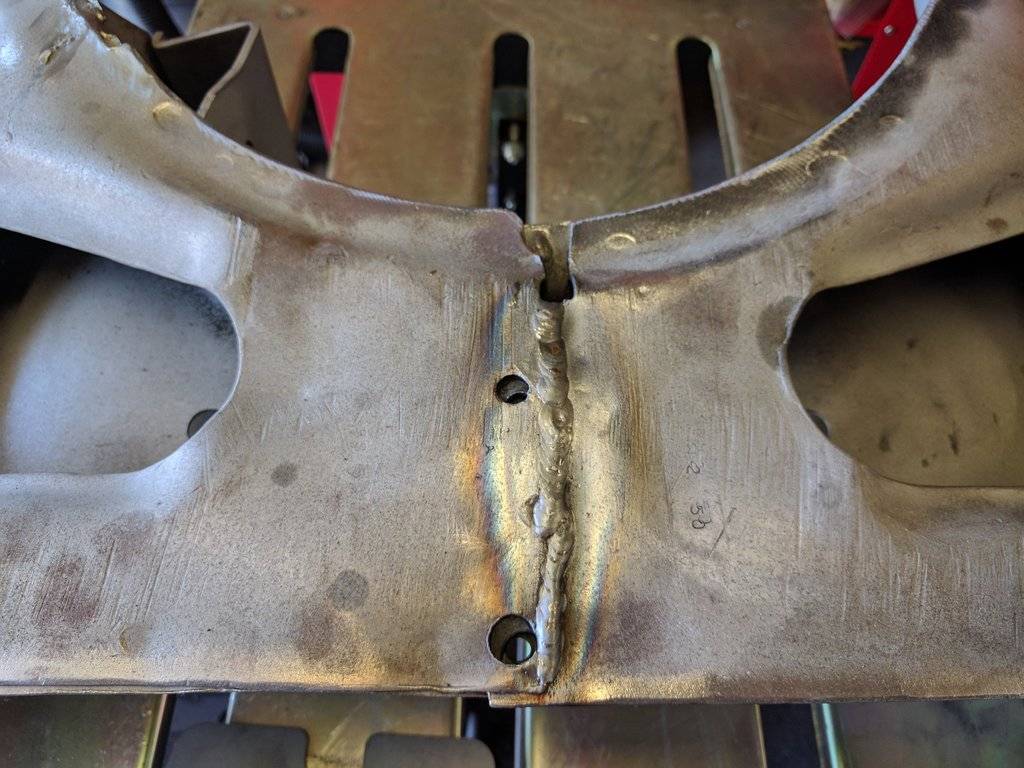

Long story short, I picked up a 73 Duster K Frame and I installed the Firm Feel stiffening kit and I welded all the seams and went over the factory welds too. Before I did all that, I had the K Frame sandblasted and after I was done with all the welding, I had it powder coated.

I had to pretty much reassemble the whole suspension and steering system. That consists of Helwig sway bar, poly lower bushings, stock upper control arm with offset bushings. While I was at it, I also installed a Borgeson steering box. I made sure to torque everything to spec and use lock-tite too.

I had it aligned to 0* camber, 3.5* caster and 1/8" toe. It drives so much better than before. Way tighter.

Now I need better wheels and tires and sub frame connectors.

Long story short, I picked up a 73 Duster K Frame and I installed the Firm Feel stiffening kit and I welded all the seams and went over the factory welds too. Before I did all that, I had the K Frame sandblasted and after I was done with all the welding, I had it powder coated.

I had to pretty much reassemble the whole suspension and steering system. That consists of Helwig sway bar, poly lower bushings, stock upper control arm with offset bushings. While I was at it, I also installed a Borgeson steering box. I made sure to torque everything to spec and use lock-tite too.

I had it aligned to 0* camber, 3.5* caster and 1/8" toe. It drives so much better than before. Way tighter.

Now I need better wheels and tires and sub frame connectors.

Welds look good, having seam welded and reinforced a couple of these now the contaminants make it tough to pull pretty welds. Especially where you go over factory welds, man the factory welds were awful.

Welds look good, having seam welded and reinforced a couple of these now the contaminants make it tough to pull pretty welds. Especially where you go over factory welds, man the factory welds were awful.