nick455440

Well-Known Member

Long story shortish, have a 65 valiant, awhile ago had done the duel reservoir master where I ran the back res to the from drum distribution block, and the front res hardline straight to the rear rubber line. Was planning on doing the same but had seen a post where some recommended using a larger reservoir master for the disks, attached is a pic of the original set up,

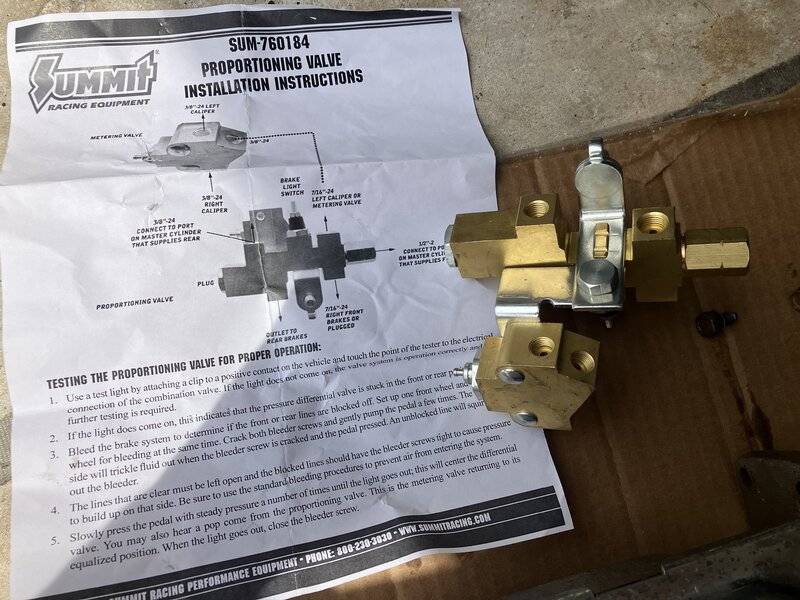

Thought about moving to this (pic below) master cylinder as it looks like it would work with the current rod set up ( I think the bore may be different) and using the summit proportioning valve (only the small block on the below pic) to run the front disks, and hardline again the other reservoir to ur rear drum rubber line,

Questions - would the original master cylinder truly be too small of a reservoir for disks and would it hurt anything to bypass the distribution block (rears only) and run the hard line straight from the master to the rear rubber line? I put frame connectors in the car and was going to run the brake line on the inside of them, instead of drilling through them, this would make the new SS front to back line to long but if I ran it to the master cylinder it would be a ideal length.. any info is appreciated

Thought about moving to this (pic below) master cylinder as it looks like it would work with the current rod set up ( I think the bore may be different) and using the summit proportioning valve (only the small block on the below pic) to run the front disks, and hardline again the other reservoir to ur rear drum rubber line,

Questions - would the original master cylinder truly be too small of a reservoir for disks and would it hurt anything to bypass the distribution block (rears only) and run the hard line straight from the master to the rear rubber line? I put frame connectors in the car and was going to run the brake line on the inside of them, instead of drilling through them, this would make the new SS front to back line to long but if I ran it to the master cylinder it would be a ideal length.. any info is appreciated