diymirage

HP@idle > hondaHP@redline

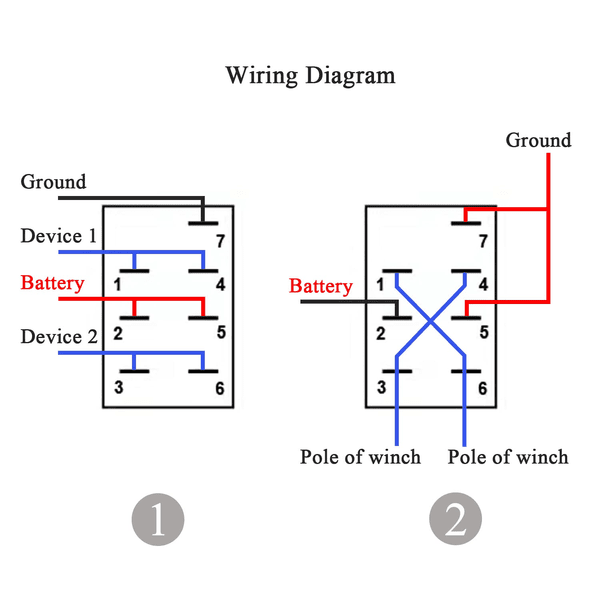

i added a rear blade to the plow over the summer and now that ive been using it, ive noticed i dont like the switches

the switches are the most basic normally open momentary switches

one wire in, one wire out

now, what i want is either one switch with two positions, or two momentary push buttons, my main concern is, i want them to light up

i think one switch would be the cleanest...would that be a DPDT switch ?

my two main concerns are that i want the switch light to be on at all times (not just when i engage it) and that i am not feeding power to anything from the switch, i simply want to use to to complete the circuit

would this switch work for that purpose?

Amazon product ASIN B09LQNZ43C

or, any other switch you guys can suggest?

the switches are the most basic normally open momentary switches

one wire in, one wire out

now, what i want is either one switch with two positions, or two momentary push buttons, my main concern is, i want them to light up

i think one switch would be the cleanest...would that be a DPDT switch ?

my two main concerns are that i want the switch light to be on at all times (not just when i engage it) and that i am not feeding power to anything from the switch, i simply want to use to to complete the circuit

would this switch work for that purpose?

Amazon product ASIN B09LQNZ43C

or, any other switch you guys can suggest?