Thanks for the tip!There's a place in Austin that does the SLS work I'm familiar with. Don't use their online quote tool, it tends to run 50% to 200% higher than a quote from an engineer. If you have a company name, real or otherwise, they'll likely take you more seriously and get you a decent price.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Peyote's 3D Printed Dash Updates

- Thread starter KevinB

- Start date

-

Ok to address the issues phreakish brought up on using ABS in a fdm print:

I talked to my printer and he has no concerns about the holes be out of round. He says he has printed circles many times in this orientation and they've always been good.

I looked up the temperature at which ABS deforms and it is 208 degrees...cars can get up to 172 degrees when it's over 100 outside, but I can't find no mentions of cars getting hotter than that. That's not a huge margin, but my printer has also printed many things in ABS for cars and he's never heard of someone having a problem.

Uv resistance is a non issue since the part will be painted.

Considering the low cost of my prototype, I think I'm on the right track

I talked to my printer and he has no concerns about the holes be out of round. He says he has printed circles many times in this orientation and they've always been good.

I looked up the temperature at which ABS deforms and it is 208 degrees...cars can get up to 172 degrees when it's over 100 outside, but I can't find no mentions of cars getting hotter than that. That's not a huge margin, but my printer has also printed many things in ABS for cars and he's never heard of someone having a problem.

Uv resistance is a non issue since the part will be painted.

Considering the low cost of my prototype, I think I'm on the right track

Phreakish

Well-Known Member

I won't disagree, and previous experience on the part of the supplier is always good.

Thermal deflection temperature can be as low as 180F with printed materials - actual material performance will be important.

I do hope it works - I'm not a rep or in anyway involved with the company I recommended - I only tossed out the suggestion because it would be a shame if all your work didn't hold up long term. Your design is excellent, just want to see the end result be as high-caliber is all.

I'll be looking forward to seeing the finished part!

Thermal deflection temperature can be as low as 180F with printed materials - actual material performance will be important.

I do hope it works - I'm not a rep or in anyway involved with the company I recommended - I only tossed out the suggestion because it would be a shame if all your work didn't hold up long term. Your design is excellent, just want to see the end result be as high-caliber is all.

I'll be looking forward to seeing the finished part!

66Dvert

Working on my custom car parts again!

The prototype print has been ordered...I'll hopefully have it in my hands in a week or so...getting excited!

you cluster is looking great BTW. I hope mine comes out looking as good too!

after I get my table enlarged to 3d print in PETG a 20 inch cluster in .05 layers, I'll refine it to the needed "smoothness" and test fit all the gauges. Once that's done it'll be cast as a master for a mold into plastic that has a High thermal value above 300 degrees.

you cluster is looking great BTW. I hope mine comes out looking as good too!

after I get my table enlarged to 3d print in PETG a 20 inch cluster in .05 layers, I'll refine it to the needed "smoothness" and test fit all the gauges. Once that's done it'll be cast as a master for a mold into plastic that has a High thermal value above 300 degrees.

Thanks! I hope mine looks as good as the model when it's done lol! What are you doing with the mold? Vacuum forming?

BTW, @Phreakish I've been reconsidering your thoughts on heat, and while it seems that cars don't get too hot for ABS, a dashboard with direct sun would be even hotter than the air temp of the car it was in. So I think you're right about that. I found a material called BluPrint that can withstand temps of up to 230 degrees...which should be plenty of cushion. I'm talking to my current printer to see if he can print with it...if not I have a couple of others I've found that will do it, the price is a little higher than ABS but not a lot more.

66Dvert

Working on my custom car parts again!

Thanks! I hope mine looks as good as the model when it's done lol! What are you doing with the mold? Vacuum forming?

no, not vacuum forming this piece. I'll be mold casting it out of a hi-temp plastic that has a good tensile strength. after I refine the master part to be super smooth and everything fitting good.

I am getting ready to put my nose to the grindstone and get some parts going as soon as I get done visiting family, ya know the weddings and graduation,birthday parties that you have to go to. couple of weeks worth of parties and meeting need to get done first.

no, not vacuum forming this piece. I'll be mold casting it out of a hi-temp plastic that has a good tensile strength. after I refine the master part to be super smooth and everything fitting good.

I am getting ready to put my nose to the grindstone and get some parts going as soon as I get done visiting family, ya know the weddings and graduation,birthday parties that you have to go to. couple of weeks worth of parties and meeting need to get done first.

Glad I'm not the only "maker" around

66Dvert

Working on my custom car parts again!

Glad I'm not the only "maker" around

I have discovered that if you own a 63-66 abody you almost have to be a maker. plus I get some neat toys to play with and the wife ain't bitching about it since one of the cars is HERS.

Last edited:

Phreakish

Well-Known Member

Thanks! I hope mine looks as good as the model when it's done lol! What are you doing with the mold? Vacuum forming?

BTW, @Phreakish I've been reconsidering your thoughts on heat, and while it seems that cars don't get too hot for ABS, a dashboard with direct sun would be even hotter than the air temp of the car it was in. So I think you're right about that. I found a material called BluPrint that can withstand temps of up to 230 degrees...which should be plenty of cushion. I'm talking to my current printer to see if he can print with it...if not I have a couple of others I've found that will do it, the price is a little higher than ABS but not a lot more.

I didn't even think about direct sun either. Good call. I'll be interested to hear what you choose.

Also didn't realize you'd be using it to make a mold and then cast reproductions. There's so many materials you can cast that will be better than any printed material that I'm sure you'll get great results.

You can also do what's called "RPM" casting - rubber, plaster, metal. The result is a die cast looking part from pourable aluminum alloys (356 or similar, like intake manifolds) or zinc alloys (pot metal). It would be total overkill, but that's how I like to do my fan work ;-)

Just a quick update...my printer has been having trouble printing the model I created. I think I got all the kinks out, and another attempt will be made tomorrow. Hopefully I'll have it by the end of the week

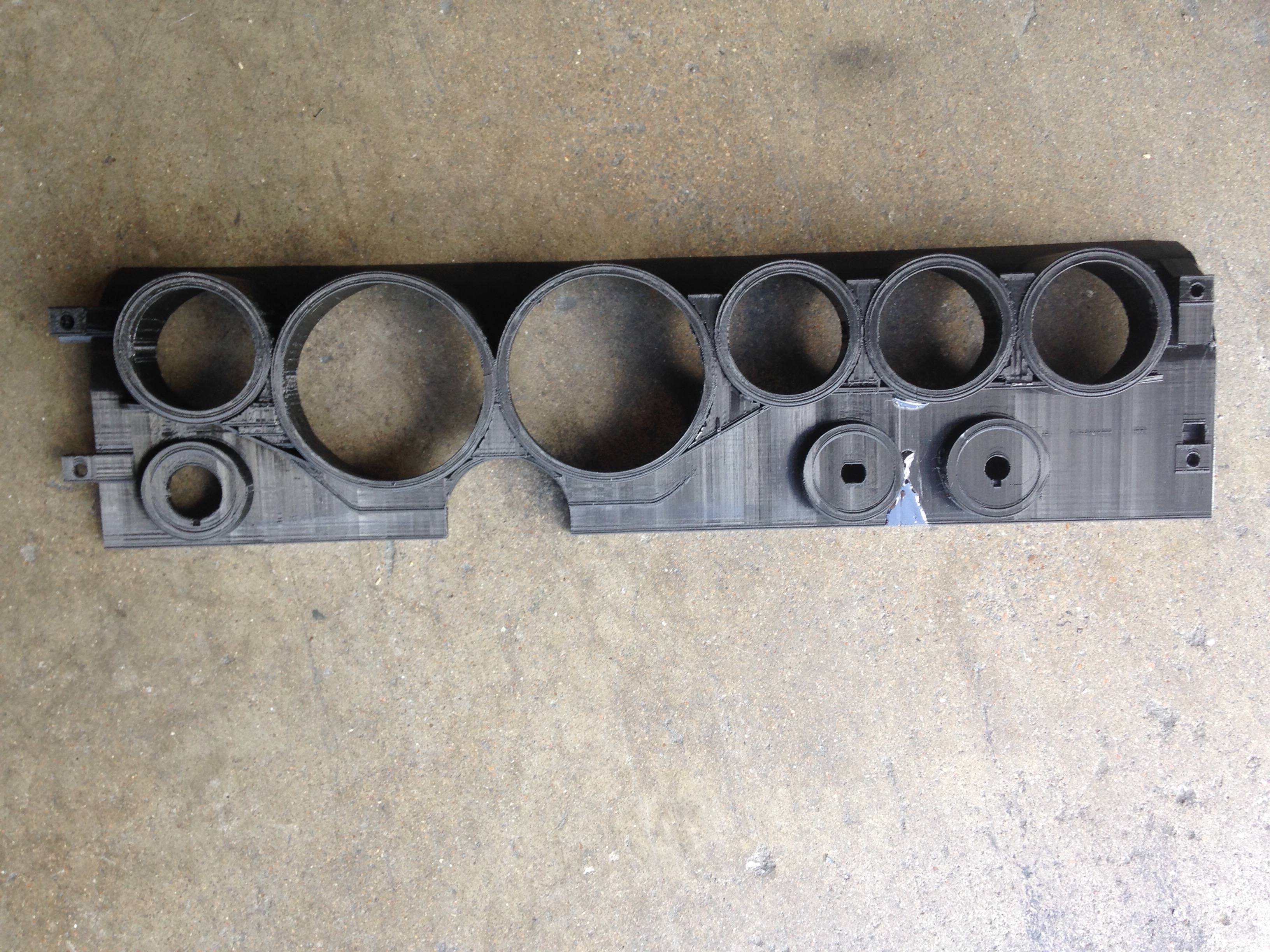

Got the prototype in! USPS cracked it for me in transit, but I slapped some epoxy on it and it will be fine for testing. The test gauges fit perfectly in the cups, they are the standard sizes. I'll have to tweak the knob holes and ignition hole just a bit as the tolerances are a little tight, but they fit as is. The ignition hole will be tweaked so that the ring goes does all the way. Tomorrow and Friday I'll play with getting it in the car, then we'll see if any other changes need to be made. So far I'm very happy.

My only second guessing would be on the gauge depth. Do you guys think they're too deep?

My only second guessing would be on the gauge depth. Do you guys think they're too deep?

Looks good!! The depth is ok, I'd bring them in towards the driver a little, maybe a quarter inch.

Looking good.

Those build lines could probably be 'vapor polished' away if you wanted:

I considered that, but I'm hoping for a traditional sanding and filler process. We will see what the final material behaves like. I should have a sample coming soon

Phreakish

Well-Known Member

I considered that, but I'm hoping for a traditional sanding and filler process. We will see what the final material behaves like. I should have a sample coming soon

It's tough to sand well. It get's a little 'gummy' and hairs tend to stand up. Plus each layer is kinda like an M&M: hard on the outside, soft in the middle. So it doesn't sand really evenly. Takes a long time to get favorable results.

If you wanted to avoid the vapor polishing, I'd use a very high build primer and hose it down and sand the primer rather than the plastic. It'll take a lot less time and give a good base for the topcoat. Adhesion promoter to begin with, of course.

Since this is your prototype part, it might also be a good idea to try a few different things and see which works best for you - personally I hate sanding plastic anymore, so I just don't ;)

It's tough to sand well. It get's a little 'gummy' and hairs tend to stand up. Plus each layer is kinda like an M&M: hard on the outside, soft in the middle. So it doesn't sand really evenly. Takes a long time to get favorable results.

If you wanted to avoid the vapor polishing, I'd use a very high build primer and hose it down and sand the primer rather than the plastic. It'll take a lot less time and give a good base for the topcoat. Adhesion promoter to begin with, of course.

Since this is your prototype part, it might also be a good idea to try a few different things and see which works best for you - personally I hate sanding plastic anymore, so I just don't ;)

I'm with you, I sanded the pla a bit and it just gets goopy. The blu-print material may behave differently, we will see. I had planned on using epoxy as a filler material since its sandable

IMO, that looks pretty freakin awesome.

Starting a piggy bank collection for one... Or two....

Starting a piggy bank collection for one... Or two....

Got the prototype in! USPS cracked it for me in transit, but I slapped some epoxy on it and it will be fine for testing. The test gauges fit perfectly in the cups, they are the standard sizes. I'll have to tweak the knob holes and ignition hole just a bit as the tolerances are a little tight, but they fit as is. The ignition hole will be tweaked so that the ring goes does all the way. Tomorrow and Friday I'll play with getting it in the car, then we'll see if any other changes need to be made. So far I'm very happy.

My only second guessing would be on the gauge depth. Do you guys think they're too deep?

View attachment 1714966011 View attachment 1714966012 View attachment 1714966013 View attachment 1714966014 View attachment 1714966015

View attachment 1714966010

Got it in and flush, I decided to cut part of the bottom of the dash rather than the top, so the mounting tabs don't line up. Other tweaks needing to be done are:

Angle the top edge of the curve back and up to close the gap to the dash cap

Lower the steering wheel cut out so it covers more of the dash frame there

Overall bottom edge extend downward by 1/2"

That's about it! Now I just need some time to make the changes and the money to send it off

Angle the top edge of the curve back and up to close the gap to the dash cap

Lower the steering wheel cut out so it covers more of the dash frame there

Overall bottom edge extend downward by 1/2"

That's about it! Now I just need some time to make the changes and the money to send it off

Mopar-Man

Big Block Better Burnout

Great design! Can't wait to see the finished product. Be sure to keep us updated.

Aussiemopars

Well-Known Member

Any updates?

Not at the moment... I'm saving up to get the car media blasted in the spring so I can shoot it with primer...I may turn my attention back to the dash once that is finished. I'm also fine with waiting a bit because there is an advantage in letting the 3d printing industry mature a bit...more printers available, better materials, etc

-

Similar threads

- Replies

- 2

- Views

- 695

- Replies

- 5

- Views

- 941

- Replies

- 24

- Views

- 584