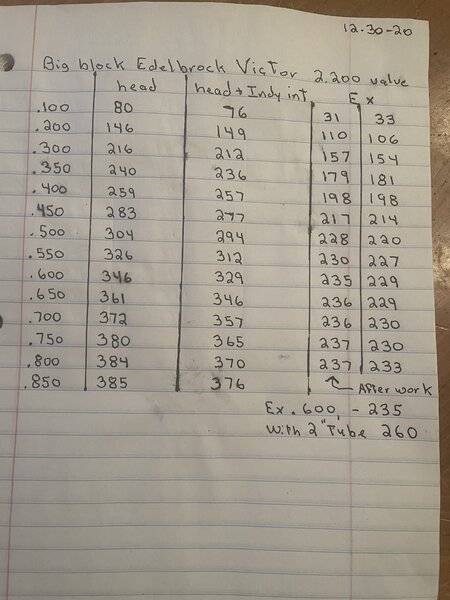

Ok Joe did a little more bowl work, widened the short-turn some, and shaped it better pushing it away from the valve seat some and removed a peak on the end of the turn. When we flow tested it I could immediately tell Joe was somewhat disappointed as he had Wednesday’s numbers and was writing today’s numbers beside them. After the flow test I backed it off to .600 lift and reset the depression to 28 inches and did some exhaust speed checks. His eyes lite up some after seeing 325fps plus speeds across the short turn. In one spot it was 400fps. The big dead spot we had was gone. Speed was up across the bowl. I let him do the probing and right away he could tell the difference. He’s very hesitant bringing any more or changing anything else and at this point I couldn’t tell him what I would have changed. If I had that head I could show him but putting it into words is impossible. This engine with the right bigger cam is going to fly. He also brought a brand new intake valve so we tested it to. We gained a few here and lost a few there but again the exhaust side had the valve job touched up and the intake side didn’t. He’s happy, I’m happy. Joe also gave me permission to take some pictures. They were buffed up with a sanding roll so the pictures aren’t as good as could be. Ohhh I should add when I put a 2 inch tube on at .600 life Wednesday we gained 11 cfm. Today at .600 we went from 235cfm to 260cfm picking up 25cfm. Nice gain.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ported Edelbrock Victor flow numbers

- Thread starter pittsburghracer

- Start date

-

bluefish

mopar dave

Nice car. Those are huge numbers on the intake side. I have the 2nd gens and my max numbers on the victor MW head are 356@.700 and 254@.700 on exhaust. My heads have the 2.200 valve and i believe these are Dwayne's numbers as i bought these from a friend of his.A good friend of mine wanted to put a set of big block Victor heads on my flow bench that he ported so we checked them out today. As always when I switch adaptors on my bench I take five minutes to check calibration. With a 300cfm calibration plate on it read 300-301cfm so that checked out good as usual. Now a little about his car. It’s a beautiful unmolested 1972 duster that weights a hair over 3500 pounds. It’s a low deck 4.500 bore stroker with a 727 transmission (transbrake) Dana rear, pretty sure it’s been 1.28 sixty foots, .690 lift roller cam, Indy intake he ported, and it’s gone 9.58 at Keystone Raceway Park. Like I said this car is beautiful and hopefully he sends me a picture or to to post up. I told him he had free bench time and we would have an enjoyable day so we spent 4 plus hours together checking flow with his intake on and check intake and exhaust airspeed.

bluefish

mopar dave

Maybe these are helpful to someone out there.Nice car. Those are huge numbers on the intake side. I have the 2nd gens and my max numbers on the victor MW head are 356@.700 and 254@.700 on exhaust. My heads have the 2.200 valve and i believe these are Dwayne's numbers as i bought these from a friend of his.

bluefish

mopar dave

Pics Intake.Maybe these are helpful to someone out there.

View attachment 1715661978

View attachment 1715661979

View attachment 1715661980

View attachment 1715661981

View attachment 1715661982

bluefish

mopar dave

RAMM

Well-Known Member

Dwayne is spot on with his comments. It's the .400" flow that always underachieves with these heads--best I've seen is 270cfm and that's still weak IMO. Usually I see around 350-357cfm peak at best no matter what size they are or who did them--in fact I had a set of CNC'd Victors that were claimed to go 390's-400's and they went 330 something. The height of the S.S. and the bowl shape won't allow much over 350cfm-they are a weird animal for sure.

@ PBR--How does your friend plan to put .750" lift into them when the install height is so short?

If I ever get/have to do another set I will mill the rocker stands off and get T&D to send me paired shaft rockers so I can fix the stupid short install height and put a longer valve and spring in it. J.Rob

@ PBR--How does your friend plan to put .750" lift into them when the install height is so short?

If I ever get/have to do another set I will mill the rocker stands off and get T&D to send me paired shaft rockers so I can fix the stupid short install height and put a longer valve and spring in it. J.Rob

RAMM

Well-Known Member

Working on my 2013 EMC ProComps at the moment-will snap some pics of what it took me to get into the 350cfm range. These particular heads make some steam. J.Rob

Dwayne is spot on with his comments. It's the .400" flow that always underachieves with these heads--best I've seen is 270cfm and that's still weak IMO. Usually I see around 350-357cfm peak at best no matter what size they are or who did them--in fact I had a set of CNC'd Victors that were claimed to go 390's-400's and they went 330 something. The height of the S.S. and the bowl shape won't allow much over 350cfm-they are a weird animal for sure.

@ PBR--How does your friend plan to put .750" lift into them when the install height is so short?

If I ever get/have to do another set I will mill the rocker stands off and get T&D to send me paired shaft rockers so I can fix the stupid short install height and put a longer valve and spring in it. J.Rob

I don’t know enough about these heads to know valve height was an issue. Probably why many step up to a bigger valve getting a longer length valve too. Like I said above we tried a new different valve yesterday on the intake while it was bolt down but he didn’t say it was longer. Kinda interesting playing with a head I never touched and taking a few pictures thinking about the changes I would make. That head could probably go 400 plus with a bigger valve and tubing it.

PRH

Well-Known Member

He didn’t mention it, but blufish’s heads were CNC’d by Hughes.

The flow test I did on the head was with the intake seat cut for a 2.25 valve, and I used a Ferrea 2.25 valve with a small back cut.

The heads were bought unfinished(blank seats), so I cut one intake and exhaust seat for the test.

By comparison, an Indy 440-1 CNC345, also with a 2.25 valve and the seats re-cut, flows very close to the same at .400 lift(looking at my notes, the last set I had here was 278).

The flow test I did on the head was with the intake seat cut for a 2.25 valve, and I used a Ferrea 2.25 valve with a small back cut.

The heads were bought unfinished(blank seats), so I cut one intake and exhaust seat for the test.

Some of this just comes down to racing flow benches, but this Hughes CNC’d head has the chamber pushed out pretty far from the valve. On my bench it flowed 281@.400 with the 2.25 valve.It's the .400" flow that always underachieves with these heads--best I've seen is 270cfm and that's still weak IMO.

By comparison, an Indy 440-1 CNC345, also with a 2.25 valve and the seats re-cut, flows very close to the same at .400 lift(looking at my notes, the last set I had here was 278).

Last edited:

Something else on this head was a little head scratching. I wish I would have put a check mark at the lift it happen but around .400 lift my digital Readout that is very touchy and shows me issues starting to happen started to flutter 5-7cfm much like the airspeed is to fast at the short turn. I stopped right there and checked the speed and it was fine. At the next lift measurement it calmed down and the cfm made a nice jump. (I’m thinking valve job) Also at higher lifts my thin airspeed checking tool was very jumpy at the top of the port entrance.( like an old time devining rod) Joe had made a very nice radius entry plate out of a nice thick plastic cutting board. I always use Duct Seal to radius the top and bottom entry of the plate to prevent a sharp edge so I turned off my flowbench to reshape it. It didn’t help and again the airspeed was fine. If they were mine curiously would make me dig into both those minor issues. Like I said earlier Joe did some very nice work on these heads and he now would love to have a flowbench. Lol. I’m almost 65 and he’s a touch older than I am so we are both pretty lucky to still have some steam in the boiler. I don’t see issues at all hitting his 9.40 ET target and 3550 pounds is not a lite weight.

Thanks to all for contributing to this post. It brings on some interesting discussion points.

RAMM

Well-Known Member

Biggest bore size I have is 4.375" that's probably why I see what I see. J.Rob

Biggest bore size I have is 4.375" that's probably why I see what I see. J.Rob

I’m kinda surprised I don’t see more issues on my small block adapter (4.010) with a 2.08 valve in my edelbrock heads.

PRH

Well-Known Member

4.375 is what I almost always use for BBM, unless the engine will have a noticeably bigger bore.

I tested a CNC345 on a 4.375 and a 4.500 bore...... zero difference in intake flow at any lift up to .800(as high as I went).

The exhaust picked up just a couple, way up at the very top.

It seems relatively widely accepted that the SF-1020 seems to generally show lower numbers than the SF-600....... and I think that’s where some of the difference is.

I’d be pretty surprised if I flowed your PC head on my bench (using the same radius plate/bore adapter I usually use)....... and the numbers I saw weren’t a bit higher than what you get.

I tested a CNC345 on a 4.375 and a 4.500 bore...... zero difference in intake flow at any lift up to .800(as high as I went).

The exhaust picked up just a couple, way up at the very top.

It seems relatively widely accepted that the SF-1020 seems to generally show lower numbers than the SF-600....... and I think that’s where some of the difference is.

I’d be pretty surprised if I flowed your PC head on my bench (using the same radius plate/bore adapter I usually use)....... and the numbers I saw weren’t a bit higher than what you get.

Last edited:

RAMM

Well-Known Member

4.375 is what I almost always use for BBM, unless the engine will have a noticeably bigger bore.

I tested a CNC345 on a 4.375 and a 4.500 bore...... zero difference in intake flow at any lift up to .800(as high as I went).

The exhaust picked up just a couple, way up at the very top.

Of course that's why I made my adapter 4.375" because its very rare that I am playing with a 4.500" bore Megablock or some other big bore Mopar. I have also seen almost ZERO difference in flow testing from small bores up to big bores--in fact I have seen slight flow losses when going from small to big because the air can't "hug" the bore wall and be directed. J.Rob

PRH

Well-Known Member

So, then I guess I’m not sure how to interpret you saying:

Biggest bore size I have is 4.375" that's probably why I see what I see.

ryan stuckey

Member

no disrespect never really messed with rb engines much but is this all the flow you can get from a cnc head? I have ported big block chevy stock 990 heads that flow a lot more than this. the lack of parts for mopars is a joke

RAMM

Well-Known Member

So, then I guess I’m not sure how to interpret you saying:

I'm giving PBR the benefit of the doubt because I have no 4.500 " bore adapter experience. I know it was confusing--sorry. I suppose its possible that a bore adapter that large could unlock that high lift flow--I just have no experience in this case. Very interesting though. J.Rob

RAMM

Well-Known Member

no disrespect never really messed with rb engines much but is this all the flow you can get from a cnc head? I have ported big block chevy stock 990 heads that flow a lot more than this.

Big Chevy stuff is light years ahead of BBM stuff so yes 385cfm is a high water mark in BBM world. J.Rob

PRH

Well-Known Member

I suppose its possible that a bore adapter that large could unlock that high lift flow

Sure........ I’ll give you that.

I haven’t tested a MW Victor on a 4.500 bore either ...... so I can’t say from experience if there is any magic in that or not.

But..... I’ll be sure to try it next time I have one here.

Joe’s head is going on a 4.500 bore so that’s why I grabbed that one. It did make me start thinking though because my 4.375 was all set up with my head studs and smaller head gasket. I was thinking at first maybe I messed up and used my smaller bore when working on my B1 heads for my 572. Then I remembered last year my local machine shop needed some work so I retested my Indy 440-1 heads before having them opened up for 2.250 intake valves. They are headed for a 512 Mega block build I have.

PRH

Well-Known Member

As an example of how “it all matters” in terms of what’s important when you’re trying to make power.

Here’s the flow up to .500 lift from a set of Indy 572-13-CNC385’s with a 2.350 valve...... tested on a 4.500 bore.

These came off a 588 that made a touch over 1000hp on Barton’s dyno.

Lift——flow

.100— 59

.200—121

.300—188

.400—253

.500—312

(Yes..... the numbers look horrible....... but the motor made over 1000hp)

Here’s the flow up to .500 lift from a set of Indy 572-13-CNC385’s with a 2.350 valve...... tested on a 4.500 bore.

These came off a 588 that made a touch over 1000hp on Barton’s dyno.

Lift——flow

.100— 59

.200—121

.300—188

.400—253

.500—312

(Yes..... the numbers look horrible....... but the motor made over 1000hp)

Last edited:

no disrespect never really messed with rb engines much but is this all the flow you can get from a cnc head? I have ported big block chevy stock 990 heads that flow a lot more than this. the lack of parts for mopars is a joke

Mopar doesn’t really offer anything stock with a 325cc intake runner before porting. You should start a post of your own and tell us about them on some “Chevy site”.

-

Similar threads

- Locked

- Replies

- 0

- Views

- 680

- Replies

- 6

- Views

- 708

- Replies

- 31

- Views

- 4K

- Locked

- Replies

- 5

- Views

- 3K

- Replies

- 84

- Views

- 10K