Hard weekend for the engine and us... below the results of a head failure...

Launched as we normal do, at first glance it sound like a fouled spark plug, the sound got a bit louder and pulled out. However, the result and damage was substantial.

We don't know exactly what failed, but it appears from what you can see as it dropped a valve seat and subsequently damage the entire cylinder head, valves, piston got substantial damage and the block sleeve cracked.

We have been running this setup without an issue, don't know what caused this. However will have to evaluate which route to take to rebuild the engine.

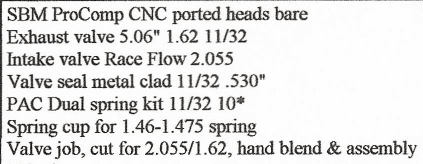

Head specs:

Heads were assembled by MRL Performance

Launched as we normal do, at first glance it sound like a fouled spark plug, the sound got a bit louder and pulled out. However, the result and damage was substantial.

We don't know exactly what failed, but it appears from what you can see as it dropped a valve seat and subsequently damage the entire cylinder head, valves, piston got substantial damage and the block sleeve cracked.

We have been running this setup without an issue, don't know what caused this. However will have to evaluate which route to take to rebuild the engine.

Head specs:

Heads were assembled by MRL Performance

, following, sorry to read.

, following, sorry to read.