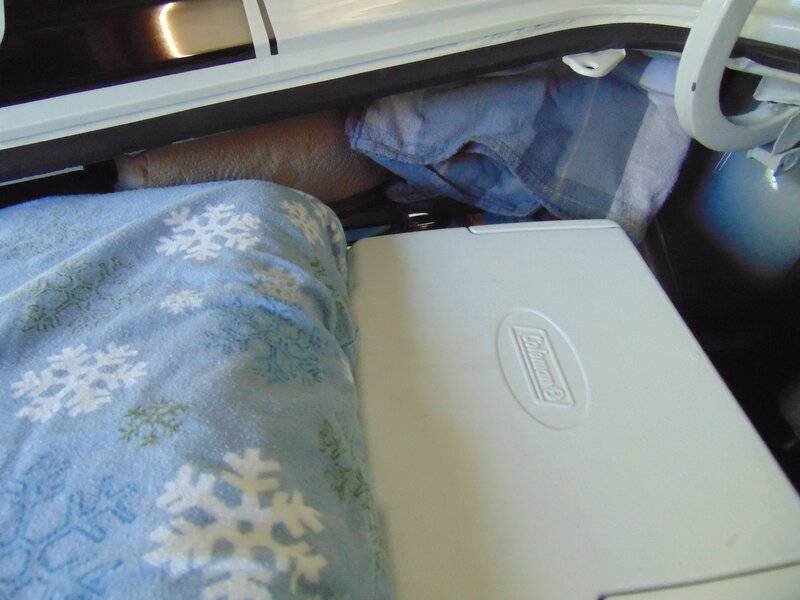

So I have seen plenty of posts here saying that you should NEVER put air shocks on a car and I have seen air shocks used improperly to cover up worn out leaf springs in a car, or to jack it up to a place where the rear suspension simply doesn't work. Today I started packing for a Thursday departure to the Rod Run to the End of the World in Ocean Park on the Long Beach Peninsula of the coast in Washington State, it's a 300 - 400 mile round trip and we will be gone for 7 days. This is what my trunk looks like at this point:

There is stiff stuck in every available nook and cranny including tool boxes, road disaster supplies and everything we need to live for that time. We are now in the process of filling the back seat up!

The leaf springs are 6 leaf ones from ESPO, maybe 4 years old. I checked the ride height in the back before I loaded it, and when it's full of maybe 5-600 lbs of stuff I'll add maybe 25 lbs of pressure in the shocks and bring it back to the usual ride height for the trip. Once we get there and unload into a rented cabin, I'll bleed some air off to restore proper ride height for 6 days of running around, and then visit a shop when it's loaded to go home to add air for the ride home.

There is stiff stuck in every available nook and cranny including tool boxes, road disaster supplies and everything we need to live for that time. We are now in the process of filling the back seat up!

The leaf springs are 6 leaf ones from ESPO, maybe 4 years old. I checked the ride height in the back before I loaded it, and when it's full of maybe 5-600 lbs of stuff I'll add maybe 25 lbs of pressure in the shocks and bring it back to the usual ride height for the trip. Once we get there and unload into a rented cabin, I'll bleed some air off to restore proper ride height for 6 days of running around, and then visit a shop when it's loaded to go home to add air for the ride home.

.

.