You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rumblefish's Duster project

- Thread starter rumblefish360

- Start date

-

Well, I did a small slew of work. I know that was just like saying military and intellagence work together, but........

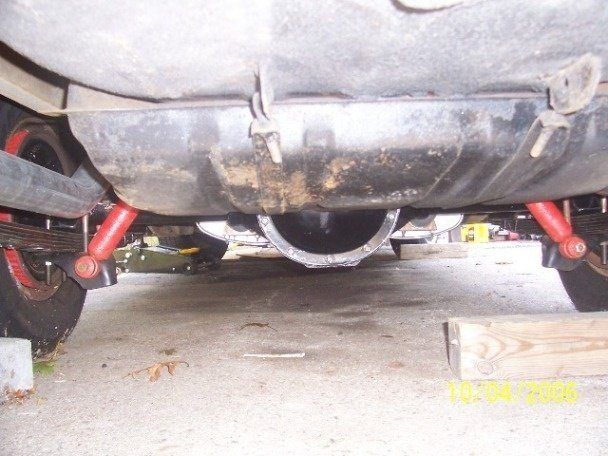

Since installing the rear end in & the drive train minus the drive shaft. I finished the exhaust minus the tips. I opted for the Jegs 2-1/2 inch exhaust kit where they suggest it is designed to fit the Hooker Comp. headers. Below are some shots. Don't mind the oil on the header. It is coated from butter & oil fingers dropping the oil filter after cam break in.

The kit required near nothing. Some pipes needed a slight help in fitment. I have a Leslie pipe expander. It helped in a expantion of a couple of pipes to the tune of maybe at best a 1/32 of an inch. Just enuff to be able to rotate the pipe easier. Otherwise, it was a fit together bolt in deal from stem to stern. It included rear pipe hangers and basic instructions. Look at them closely and you'll get it.

They surplied clamps that worked very well. Clamps almost allways stink. Not this time. Very slight leakage. I'll weld them at a later date.

The only thing not surplied was hangers for the mufflers. Universal units may be emploied here. Then you'll need a drill to go through the body behind the rear seat. A Nut and bolt with washers (Lock would be good) to hang the hangers and mufflers up high.

Since installing the rear end in & the drive train minus the drive shaft. I finished the exhaust minus the tips. I opted for the Jegs 2-1/2 inch exhaust kit where they suggest it is designed to fit the Hooker Comp. headers. Below are some shots. Don't mind the oil on the header. It is coated from butter & oil fingers dropping the oil filter after cam break in.

The kit required near nothing. Some pipes needed a slight help in fitment. I have a Leslie pipe expander. It helped in a expantion of a couple of pipes to the tune of maybe at best a 1/32 of an inch. Just enuff to be able to rotate the pipe easier. Otherwise, it was a fit together bolt in deal from stem to stern. It included rear pipe hangers and basic instructions. Look at them closely and you'll get it.

They surplied clamps that worked very well. Clamps almost allways stink. Not this time. Very slight leakage. I'll weld them at a later date.

The only thing not surplied was hangers for the mufflers. Universal units may be emploied here. Then you'll need a drill to go through the body behind the rear seat. A Nut and bolt with washers (Lock would be good) to hang the hangers and mufflers up high.

Cerwin

Well-Known Member

looks nice, i guess the piping doesnt come with a balance pipe?

will you install one later? or will you keep it all side by side with no h pipe?

Cerwin

will you install one later? or will you keep it all side by side with no h pipe?

Cerwin

I was going to comment on that and forgot to add it in. The kit is balance pipeless. For the extra money for it, it would be a good thing to add in. I have no plans to add the "H" pipe ASAP or soon. I have another mound of things to contend with. (And it's alllways a bummer. He he he)

For, what? About $40 or less? The "H" pipe should be purchased and spliced in. It is an easy thing. The V bent pipe shold be used in this case. Reason being is the area where the pipe runs straight for the easy route may interfear with the drive shaft. But as you see, theres no shaft.

The V pipe can cut the angle I believe in where the pipes come towards each other. Right around the tranny crossmember is would be a great area.

But you shoud think before you cut, and look and mesure twice, thats my advice.

(Crap, I think Ive been reading to many Dr, Suess books for bed time storys....)

For, what? About $40 or less? The "H" pipe should be purchased and spliced in. It is an easy thing. The V bent pipe shold be used in this case. Reason being is the area where the pipe runs straight for the easy route may interfear with the drive shaft. But as you see, theres no shaft.

The V pipe can cut the angle I believe in where the pipes come towards each other. Right around the tranny crossmember is would be a great area.

But you shoud think before you cut, and look and mesure twice, thats my advice.

(Crap, I think Ive been reading to many Dr, Suess books for bed time storys....)

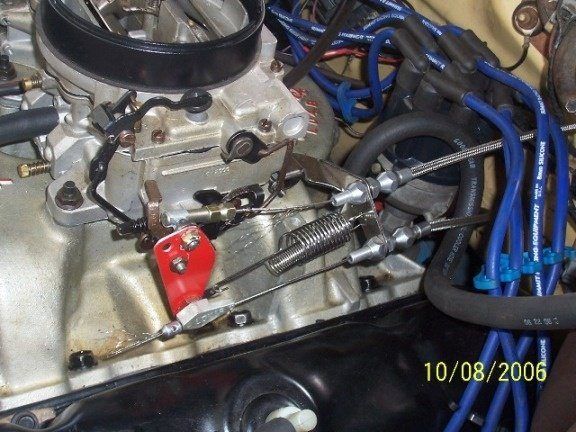

On the throttle cable issue that you may have seen me post about, I could not locate a stock one. So I went to Lokar. There instructions were blury and basicly sucked. So first timers or newbies will have a problem. It may take a few minutes to figure it out. For myself, had there pictures drawing not look like a kids smudge, I still would not have been happy. The real problem was a in the ordering. A mistake was made.

They do not make a cable for stock carbs.

To this end, I made a metal plate to minic the Carter/Edelbrock adapter linkage. It's a simple thing really. Take note of where the cable hooks up. The area is NOT on OE carbs. A spare peice of tin and a nibbler.....drill bits to find out what size the holes are, a few minutes later, presto, below is what I came up with.

Tomorrow I'll sanp a few shots with the kick down cable installed.

They do not make a cable for stock carbs.

To this end, I made a metal plate to minic the Carter/Edelbrock adapter linkage. It's a simple thing really. Take note of where the cable hooks up. The area is NOT on OE carbs. A spare peice of tin and a nibbler.....drill bits to find out what size the holes are, a few minutes later, presto, below is what I came up with.

Tomorrow I'll sanp a few shots with the kick down cable installed.

Heres the kickdown cable added. I should have gotten the trans side shot. I'll have to do that later when I do the shifter. But this is how it looks. Not a final stage of putting it together.

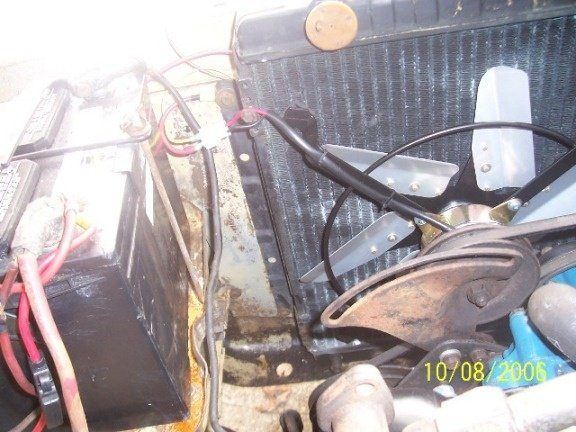

Heres the electric fan installed. Positioned out of the way of the water pump pulley and away from a possible engine mount failure for sandwich type mounts, which I do not have, but thats a safer area since the engine will move away from it should something happen.

Last shot is the controller. Not finished mounting it. But thats where it will go. I just ran the wires under the lip of the rad. suport to the battery. Becareful when you close the hood or you will crac the case of the controller. Some wires were left uncut. Like the (Blue) wire for the A/C and the second leed for dual fans. Hey, ya never know and it doesn't bother me being wraped up to the side. Out of site, out of mind.

Last shot is the controller. Not finished mounting it. But thats where it will go. I just ran the wires under the lip of the rad. suport to the battery. Becareful when you close the hood or you will crac the case of the controller. Some wires were left uncut. Like the (Blue) wire for the A/C and the second leed for dual fans. Hey, ya never know and it doesn't bother me being wraped up to the side. Out of site, out of mind.

Longgone

John/68 Barracuda & Dart

This is a very well done thread Rumble! I wonder if Adam can move it to the members resto section where it can be appreciated? Once again, very nicely done!

Thank dude. I remember he said someting about it. I chimed in on the thread. Then forgot about it. It would be better in the car fixer upper/resto section.

It'll pick up again on the B&M shifter install. Instructions are easy.

Then it may wait awhile. The cars outside and welding in floor pans may take some time. (He he he he.)

It'll pick up again on the B&M shifter install. Instructions are easy.

Then it may wait awhile. The cars outside and welding in floor pans may take some time. (He he he he.)

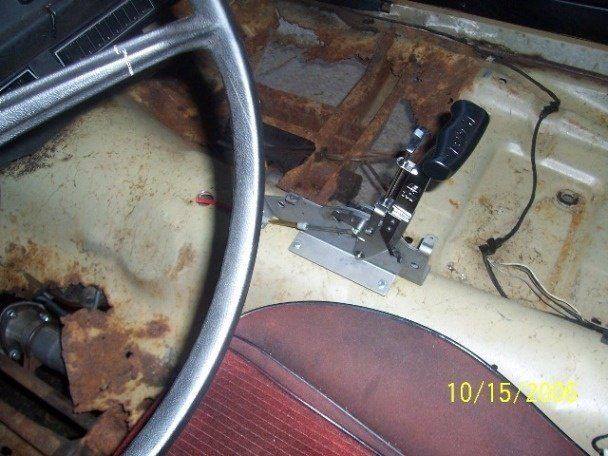

Well, I waited till I did some more work before I gave you the rear lokar cable mount shot, but thats first up. Easy install.

Next would be a series of shots on the shifter and parts.

The first one being the cable holding plate. Remove the tranny pans 2 left (Drivers) pan bolts and intall with hardware. I used 2 unseen spacers to move the bracket away from the pan. (Downward)

Next is a shot of the cable installed into the bracket and the cable installed on the B&M surpplied lever. You remove the stock arm (Lever) and replace it with the B&M unit. It is straighter and shorter by compare.

Again only from infront of the header collector.

Then 2 shifter shots.

As you can see, I need floor pans bad. Last 2 shot. Ha ha ha. Thats almost next. Gotta do a little frame repair next. (Joooooooooy)

For some reason, the pictures didn't load as selected. ????????

Next would be a series of shots on the shifter and parts.

The first one being the cable holding plate. Remove the tranny pans 2 left (Drivers) pan bolts and intall with hardware. I used 2 unseen spacers to move the bracket away from the pan. (Downward)

Next is a shot of the cable installed into the bracket and the cable installed on the B&M surpplied lever. You remove the stock arm (Lever) and replace it with the B&M unit. It is straighter and shorter by compare.

Again only from infront of the header collector.

Then 2 shifter shots.

As you can see, I need floor pans bad. Last 2 shot. Ha ha ha. Thats almost next. Gotta do a little frame repair next. (Joooooooooy)

For some reason, the pictures didn't load as selected. ????????

Cerwin

Well-Known Member

and i thought my floors were bad.. you make me feel better. thanks Rumble.

Did you go fro a b&m over a hurst for any specific reasons?

Cerwin

Did you go fro a b&m over a hurst for any specific reasons?

Cerwin

Cerwin;

No. Though I didn't see any cheap Hursts in the books, I know I can get an inexpensive Hurst if I opebed up a web page. I do not have the recipt handy. But cheap is the operative word.

No. Though I didn't see any cheap Hursts in the books, I know I can get an inexpensive Hurst if I opebed up a web page. I do not have the recipt handy. But cheap is the operative word.

Late to respond, but your welcome dartly.

I've been fighting to get the time to do something on it. Well;

I got the driveshaft cut and installed. Though I promtly broke a bolt in the rear yoke while putting on the straps. (GREAT!!!!!!!)

Started it up after replaceing very fouled plugs (on both cars no less) to check trans fluid level. (Jury still out, ran out of time)

However, that took alot of time due to the carb flooding up and over the top. Took it apart twice. Replace a float that sank, then rebend the float so it shuts off the fuel flow.

Swapped out a couple of metering rods, but was interupted by the float problem. If I'm home tomorrow day, I'll try to tune it up a tad. I really want to weld in the 02 bung to help out some.

Emptied the rad of (Just) water and added antifrezze to the mix. Last couple of days has been getting to a low of 37. Thats just 5*'s above the frezze zone and fair warning to do something before it becomes to late.

Stopped to cobble up a homemade heat stove for the headers on the MAgnum. Simple bending up of metal into a "U" shape to form the stove. I'll cut slits in the legs of the "U" and run a strap through it to hold it up and inplace. A 2 inch hole for the flexable pipe to the air cleaner. Presto, good to go.

I've been fighting to get the time to do something on it. Well;

I got the driveshaft cut and installed. Though I promtly broke a bolt in the rear yoke while putting on the straps. (GREAT!!!!!!!)

Started it up after replaceing very fouled plugs (on both cars no less) to check trans fluid level. (Jury still out, ran out of time)

However, that took alot of time due to the carb flooding up and over the top. Took it apart twice. Replace a float that sank, then rebend the float so it shuts off the fuel flow.

Swapped out a couple of metering rods, but was interupted by the float problem. If I'm home tomorrow day, I'll try to tune it up a tad. I really want to weld in the 02 bung to help out some.

Emptied the rad of (Just) water and added antifrezze to the mix. Last couple of days has been getting to a low of 37. Thats just 5*'s above the frezze zone and fair warning to do something before it becomes to late.

Stopped to cobble up a homemade heat stove for the headers on the MAgnum. Simple bending up of metal into a "U" shape to form the stove. I'll cut slits in the legs of the "U" and run a strap through it to hold it up and inplace. A 2 inch hole for the flexable pipe to the air cleaner. Presto, good to go.

7demon2

Registered User #1824

i agree it should be there. this is too good a thread to not be in there.Longgone said:This is a very well done thread Rumble! I wonder if Adam can move it to the members resto section where it can be appreciated? Once again, very nicely done!

7demon2

Registered User #1824

hey..... it made it here! thanks for moving it guys!

WOW! The peoples voives were heard and I thannk you!

More to come later, but not today. Overtime call! (Ka-Ching! $$$$$$$)

Going to N.Y.C. for a extra bone in the paycheck.

:wav:

More to come later, but not today. Overtime call! (Ka-Ching! $$$$$$$)

Going to N.Y.C. for a extra bone in the paycheck.

:wav:

Heres a little tuning helper. I have had this Edelbrock air/fuel gizmo for a while now. I used it on my Cuda. It really helps. I know theres better, more advanced on the market, but at the time, there was only 2 others to chose from that had a reasonable price tag.

You have to do some drilling and welding. Don't be afraid if you have never done it before. Just grab a freind for help. No freinds around, just grab the mig, read the instructions and go to town on some scrap meatl and figure it out.

I practiced on this exhaust cuplink (2-1/2 inch) first. Not knowing how to set the mig up ot the gauge of the pipe or the thickness of the bung thats being welded in, I played around.

The bung required a 7/8 hole. A simple hole saw for the 3/8 drill did the job. A tie wrap held it inplace for me. I didn't have vise grips that large.

For those who have not used a mig welder, it's not hard to operate. The main thing is getting the weld hot enuff to melt into the pipe and bung well. Basicly, think of it as glueing. The glue is hot enuff to melt into the metal. And this is a must. To achieve this, theres a dial on the welder to increase the heat. To much and you'll just burn right through the metal.

Practice before you do the real deal. After a few trys, I got it.

To hook up the Edelbrock o2 unit;

1 wire is a positive RED wire. Hook it up to a wire that is live when the ignition is on, dead when the key is out.

1 Ground wire. Instructions say hook it to the engine block. I attached it to the back of the drivers head.

The other wires go to the 02 sensor. I just velcroed the unit (Edelbrock also surplied the velcro) to under the A/C unit. Easy to see.

3rd picture........Who says rotted floor boards can be a bennifit? Ha ha ha. It made this part easy. Same steps as in the practice welding.

Last shot.....OK, My welds look like Fido A$$, but it isn't easy on your back with limited ground clearance.

If your wondering if it is all good when you do it, take a small pen light/Mag Lite and turn it on and shine it into the bung. If you see light, you missed a spot and you'll need to go back with the mig and close it up.

Recheck when the car is on. Feel for a hot puff of air and/or a black spot from leaking exhaust gas.

Edelbrock o2 kit was about $100 bucks. It's a few years old. Not really counted in the total tally due to it being a on the shelf extra part with multi car useage. But it is something a rookie tuner can use to there bennift and IMO, worthy to add into this thread and worth the cost for carb tuning. Exper. or not in tuning a carb.

Drill bit/hole saw was about $10

Bung was $7 or 8 bucks. Jegs has'em. (Though Edelbrock does surply one in the kit.)

Once I get the carb tuned or right close in the ball park, (Weather changes and so does the state of tune, but ball park term is realitive.) The o2 sensor comes out and the plug for the bung goes in.

A device like this can help get the part throttle and W.O.T closer to what is best. When I was running my 750 AFB on the 360 Cuda, it never had a problem. Ran well, screamed up top, no hiccups, burps, sputters etc...

When the o2 was installed, it was a tad rich at idle, fine at cruise, a little lean at part throttle and stupid lean at W.O.T.

A day palying around and it made a big difference.

You have to do some drilling and welding. Don't be afraid if you have never done it before. Just grab a freind for help. No freinds around, just grab the mig, read the instructions and go to town on some scrap meatl and figure it out.

I practiced on this exhaust cuplink (2-1/2 inch) first. Not knowing how to set the mig up ot the gauge of the pipe or the thickness of the bung thats being welded in, I played around.

The bung required a 7/8 hole. A simple hole saw for the 3/8 drill did the job. A tie wrap held it inplace for me. I didn't have vise grips that large.

For those who have not used a mig welder, it's not hard to operate. The main thing is getting the weld hot enuff to melt into the pipe and bung well. Basicly, think of it as glueing. The glue is hot enuff to melt into the metal. And this is a must. To achieve this, theres a dial on the welder to increase the heat. To much and you'll just burn right through the metal.

Practice before you do the real deal. After a few trys, I got it.

To hook up the Edelbrock o2 unit;

1 wire is a positive RED wire. Hook it up to a wire that is live when the ignition is on, dead when the key is out.

1 Ground wire. Instructions say hook it to the engine block. I attached it to the back of the drivers head.

The other wires go to the 02 sensor. I just velcroed the unit (Edelbrock also surplied the velcro) to under the A/C unit. Easy to see.

3rd picture........Who says rotted floor boards can be a bennifit? Ha ha ha. It made this part easy. Same steps as in the practice welding.

Last shot.....OK, My welds look like Fido A$$, but it isn't easy on your back with limited ground clearance.

If your wondering if it is all good when you do it, take a small pen light/Mag Lite and turn it on and shine it into the bung. If you see light, you missed a spot and you'll need to go back with the mig and close it up.

Recheck when the car is on. Feel for a hot puff of air and/or a black spot from leaking exhaust gas.

Edelbrock o2 kit was about $100 bucks. It's a few years old. Not really counted in the total tally due to it being a on the shelf extra part with multi car useage. But it is something a rookie tuner can use to there bennift and IMO, worthy to add into this thread and worth the cost for carb tuning. Exper. or not in tuning a carb.

Drill bit/hole saw was about $10

Bung was $7 or 8 bucks. Jegs has'em. (Though Edelbrock does surply one in the kit.)

Once I get the carb tuned or right close in the ball park, (Weather changes and so does the state of tune, but ball park term is realitive.) The o2 sensor comes out and the plug for the bung goes in.

A device like this can help get the part throttle and W.O.T closer to what is best. When I was running my 750 AFB on the 360 Cuda, it never had a problem. Ran well, screamed up top, no hiccups, burps, sputters etc...

When the o2 was installed, it was a tad rich at idle, fine at cruise, a little lean at part throttle and stupid lean at W.O.T.

A day palying around and it made a big difference.

Well, I'm writing to keep you updated.

Gotta get into the AVS, she won't idle. Thinking about trying the 750 Carter AFB I have on a shelf just for fun. I'd like to time it someday. :-#

I had it fine for a lil'while, then she got cranky.

The Edel. 02 sensor is blinking out on me. Looking for a cheap replacement. However, been thinking about a serious up grade. There spendy. (Ouch!) I at least got the A/F leaner to 13-1 from a sloid 12+.

Also, on tools, I need to replace a gator clip on a hand held Sears gizmo. (Rpm/Dwell?volts/Ohms gaddget) and a timing light. Could be helpful later. He he he...Ooooooooooooo boy :disgust:

Now that I think about it, I could spend about 2 bills on replacement tools since the summer. All well. Heres hoping for a short warm winter! :coffee2:

Gotta get into the AVS, she won't idle. Thinking about trying the 750 Carter AFB I have on a shelf just for fun. I'd like to time it someday. :-#

I had it fine for a lil'while, then she got cranky.

The Edel. 02 sensor is blinking out on me. Looking for a cheap replacement. However, been thinking about a serious up grade. There spendy. (Ouch!) I at least got the A/F leaner to 13-1 from a sloid 12+.

Also, on tools, I need to replace a gator clip on a hand held Sears gizmo. (Rpm/Dwell?volts/Ohms gaddget) and a timing light. Could be helpful later. He he he...Ooooooooooooo boy :disgust:

Now that I think about it, I could spend about 2 bills on replacement tools since the summer. All well. Heres hoping for a short warm winter! :coffee2:

'64 Cuda

Well-Known Member

Hey Rumblefish, I came across this thread & just now finished reading it. I think it's great you're taking the time to show this to everybody. I'd guess a lot of us had to figure this kind of stuff out on our own, with no one else to bounce ideas off of or help us out. I know I've been down a similar road before.

I noticed you asked a question back in July about the little thing with the spliced wire on the left fenderwell. I never saw any answer so I'll throw in my 2 cents here. It looks like part of the seat belt starter interlock system. Most people don't even know they ever existed. As I remember, NHTSA or some other Govt. PITA decided we needed to be forced to wear our seatbelts so they required the auto makers to install a system that required you to fasten your seatbelts before you could start the car. The systems had weight sensors in the front seats so if you put a heavy bag of groceries on the passenger seat you would have to fasten that seatbelt too. The factories had to engineer the systems in a hurry because the Govt. didn't give them a lot of lead time, which might partly explain why they didn't work very well. I think the systems were abolished after about 6 months. The story I heard at the time was that somebody checked the cars of the people that worked at the Govt. agency that had required the systems & found that 50% of them (it might have been a lot more, I'm old, so I don't remember too well!) had bypassed the systems in their own cars. I once had a discussion a few years ago about these systems with a person who worked in DC (& was very big on what she, personally, had accomplished for the public safety & good) at the time they were used & she insisted no such system ever existed.

OK. Enough of my rambling. To further answer your question, all of these systems had a switch under the hood to bypass them if they failed. The device in your picture looks like it has a button on it. Push the button, bypass the system, start the car, without using your seatbelts. The bypass was temporary. You had to open the hood & press the button each time you wanted to start the car. They were a big PITA. My wife had one on a '74 Dart & I had one on a '74 VW Beetle.

:burnout:

I noticed you asked a question back in July about the little thing with the spliced wire on the left fenderwell. I never saw any answer so I'll throw in my 2 cents here. It looks like part of the seat belt starter interlock system. Most people don't even know they ever existed. As I remember, NHTSA or some other Govt. PITA decided we needed to be forced to wear our seatbelts so they required the auto makers to install a system that required you to fasten your seatbelts before you could start the car. The systems had weight sensors in the front seats so if you put a heavy bag of groceries on the passenger seat you would have to fasten that seatbelt too. The factories had to engineer the systems in a hurry because the Govt. didn't give them a lot of lead time, which might partly explain why they didn't work very well. I think the systems were abolished after about 6 months. The story I heard at the time was that somebody checked the cars of the people that worked at the Govt. agency that had required the systems & found that 50% of them (it might have been a lot more, I'm old, so I don't remember too well!) had bypassed the systems in their own cars. I once had a discussion a few years ago about these systems with a person who worked in DC (& was very big on what she, personally, had accomplished for the public safety & good) at the time they were used & she insisted no such system ever existed.

OK. Enough of my rambling. To further answer your question, all of these systems had a switch under the hood to bypass them if they failed. The device in your picture looks like it has a button on it. Push the button, bypass the system, start the car, without using your seatbelts. The bypass was temporary. You had to open the hood & press the button each time you wanted to start the car. They were a big PITA. My wife had one on a '74 Dart & I had one on a '74 VW Beetle.

:burnout:

'64 Cuda; Thanks. I remember my mechanic telling me of this sometime back. He was a carear (sp) Chrysler mech. here in N.Y. Reired and opened up a Muscle car shop. Chrysler OE/ performance based.

On the thread, thanks again. In this, I'll be show caseing my smarts as well as stupidness. He he he. (We all know I do not spell to well. He he he.)

If it works, or fails, you'll know about it.

With lots of 318's out there going unused, this should help gain some support for them since going bigger isn't allways an option.

This should be fun.

On the thread, thanks again. In this, I'll be show caseing my smarts as well as stupidness. He he he. (We all know I do not spell to well. He he he.)

If it works, or fails, you'll know about it.

With lots of 318's out there going unused, this should help gain some support for them since going bigger isn't allways an option.

This should be fun.

Captainkirk

Old School Mopar Warrior

Rumble, kinda lost track of your thread for a bit....I must say I'm impressed! You're making great progress. No way I can keep up with you.

Just keep it coming, this is a great thread!

Just keep it coming, this is a great thread!

Ha ha ha, it fell of the screen, literally. (sp)

I'll be back with a cost count total later and then in spring. Unless I win big at a lotto or something.

I'll be back with a cost count total later and then in spring. Unless I win big at a lotto or something.

I might have missed something, other than small fry expense's like brake cleaner, oil, filters, gear oil for the rear, etc... But there also replaceables and constant. Allways a good thing to replace IMO, on a new ride when you get'er home. Just seems to make sense to start fresh on a few things with a new project car.

It will at least take a few variables out of the problems that may occur.

So, this is the basic deal;

Car, tires and Sony Explodes with the On My Shelf stero head unit and oldie Radio Shack amp @ 100 X 2, with assoc. wires and what nots...............................................................$1810.

Total of parts purchased for upgrades..................$1821

Total thus far on car, $3631.25

Not yet installed (or tallied) is the front drum to disk brake parts. I scooped up everything w/poly bushings for $200. I also have On My Shelf, from a Cordoba parts car, the large disks brakes. The caliper brackers and disks are from a current on going project. The Magnum. A project turned everyday driver due to the death of the everyday car.

I priced everything out for the disk installation and it's under hundred bucks. So we can assume the tally rises to $4000 at a max.

The only caveat I have run into thats a bummer is the OE Carter AVS not working right. I think I'm missing something easy. I swapped it out, on a temp basis, my Cuda's 750 AFB. (Fed-Mogaul unit.)

The thought of spending money on a fresh 650 Edelbrock AVS is a entertaining thought. Also a new A/F ratio monitor/guage. The Edelbrock version I have is old and crapping out.

Though this is supposed to be an exercise of, "On the Cheap." as much possible that is.

Then were onto metal. Time to try the hand at some body work.

( He he he, OH Joy!!! Another $4000?????)

It will at least take a few variables out of the problems that may occur.

So, this is the basic deal;

Car, tires and Sony Explodes with the On My Shelf stero head unit and oldie Radio Shack amp @ 100 X 2, with assoc. wires and what nots...............................................................$1810.

Total of parts purchased for upgrades..................$1821

Total thus far on car, $3631.25

Not yet installed (or tallied) is the front drum to disk brake parts. I scooped up everything w/poly bushings for $200. I also have On My Shelf, from a Cordoba parts car, the large disks brakes. The caliper brackers and disks are from a current on going project. The Magnum. A project turned everyday driver due to the death of the everyday car.

I priced everything out for the disk installation and it's under hundred bucks. So we can assume the tally rises to $4000 at a max.

The only caveat I have run into thats a bummer is the OE Carter AVS not working right. I think I'm missing something easy. I swapped it out, on a temp basis, my Cuda's 750 AFB. (Fed-Mogaul unit.)

The thought of spending money on a fresh 650 Edelbrock AVS is a entertaining thought. Also a new A/F ratio monitor/guage. The Edelbrock version I have is old and crapping out.

Though this is supposed to be an exercise of, "On the Cheap." as much possible that is.

Then were onto metal. Time to try the hand at some body work.

( He he he, OH Joy!!! Another $4000?????)

69signetv8

Well-Known Member

Hall of Fame write-up. Thanks for taking the time you put into it without losing base Rumble it's excellent :thumbup:

:wav:

:wav:

-

Similar threads

- Replies

- 0

- Views

- 182