You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

S/B rocker arm geometry and contact patch

- Thread starter rumblefish360

- Start date

-

I wonder how long he has been doing this service?I can’t believe this thread went for so long without Mikes (B3) name popping up !

aaronk785

Well-Known Member

Mike at b3 helped me on a ford small block. Different system but he was more worried about sweep width than being perfectly centered.

I wonder how long he has been doing this service?

Quite a while ...I used him on both my W2 and Magnum head builds. He had me take measurements and pics then he advised on how much to shim or change pushrod length .

Both came out spot on .

yellow rose

Overnight Sensation

There are a zillion threads here on “what cam” and if you start searching the forum from day one you notice they are all shelf cams being recommended. When did all the custom cam grinding become all the rage anyway? How did we survive!!!Just another interesting observation on a slow news day twiddling thumbs!

Custom cam grinding came about in the 1980's when guys were sick of running junk.

Welcome to the 1980's.

And it was well before that for the pro racers.

I know, was just referring to this forum. Had lots of time and was wading through the beginnings of a ton of cam posts on this forum and honestly I think I saw the first post from 2009, someone mentioning picking from lobes on a list. And it was someone who built engines. Just an observation of of a regular schlub such as myself who had his eyes opened when I joined this forum in 2016. Catalog shopper until then.Custom cam grinding came about in the 1980's when guys were sick of running junk.

Welcome to the 1980's.

And it was well before that for the pro racers.

Thanks! I may need his services.

My kit came in last week, $200 is the current price.

Last edited:

I know, was just referring to this forum. Had lots of time and was wading through the beginnings of a ton of cam posts on this forum and honestly I think I saw the first post from 2009, someone mentioning picking from lobes on a list. And it was someone who built engines. Just an observation of of a regular schlub such as myself who had his eyes opened when I joined this forum in 2016. Catalog shopper until then.Oh, and I’m going custom from here on out!

Yep. Learned a lot about cams and I am still miles away from being knowledgeable. I think a good cam grinder understands the positives of Mopar's large lifter and uses lobes designed to maximise that.

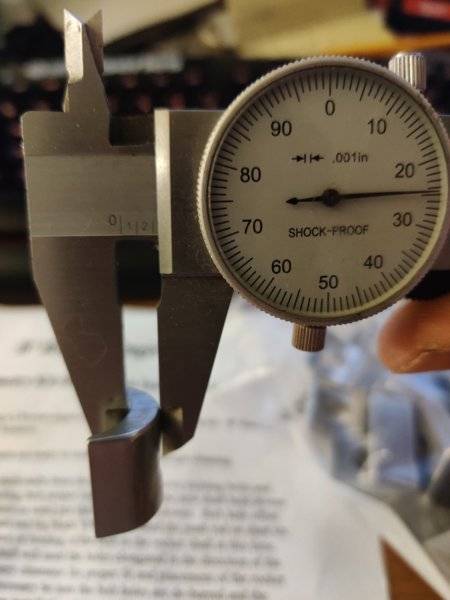

Thanks for posting. I always was curious as to what the components looked like. (and the price as well)My kit come in last week, $200 is the current price. View attachment 1715446246

yellow rose

Overnight Sensation

My kit came in last week, $200 is the current price. View attachment 1715446246

The cheapest, best 200 bucks you can spend. Dollar for dollar it's hard to beat his kits.

Ok YR, u have stated numerous times that shims are the wrong way of adjusting rocker shafts for valve tip alignment and sweep and push rod length. Is this not shims? Or am I missing something? KimThe cheapest, best 200 bucks you can spend. Dollar for dollar it's hard to beat his kits.

yellow rose

Overnight Sensation

Ok YR, u have stated numerous times that shims are the wrong way of adjusting rocker shafts for valve tip alignment and sweep and push rod length. Is this not shims? Or am I missing something? Kim

When I said shims, I meant shims like Hughes is selling, among others. They are just a flat .015, .030 and .060 shim with a hole in it that has a curve to sit in the saddle.

That only does half of what you need. If the shaft needs to go up, it also needs to move AWAY from the valve. There is a mathematical formula for how much up and how much away you need. I don't know it, but Mike at B3 does.

When you buy his kit, the "shims" aren't really a shim at all. They had a radius for the saddle in the head and a radius for the shaft and the shim is offset. That means it's thinner on one side. So it will move the shaft up, and then away from the valve. And you have to offset the hole in the shaft so it can move away.

Just raising the shaft is only half of it.

That's why Mikes kit is different. It isn't just 3 different thicknesses of shim. IIRC my shims are .200 thick and then however much away they move the shaft.

I've seen pictures of his shims that correct the height much more than my puny .200.

That's the same principle as using stands like the W2 head does. With longer valves and different rockers...some with roller tips all require a different height and offset.

So, you can either mill the stands and use offset blocks and shafts, or just buy Mikes kit.

My first dealing with the offset stuff was on a buddy's T/A stuff he bought. It was late 1981 when he drug all that crap home. I no longer remember the name of the guy who turned us on to the W2 stuff for his T/A heads, but he did the original set of heads I've ever seen it done on. An we bought the parts on my dads account at Roy Burnett Chrysler-Plymouth.

It's not something that is new or unknown.

Edit: from the picture above its a bit hard to see what I'm saying about the offset of the shim. Maybe GLH can post some pictures with different angles so it's easier to see.

Also it looks like he didn't need a bunch of correction.

Thanks for the tutorial. Kim

Looks like a nice kit. Kim

Looks like a nice kit. Kim

Heads are still at PRH, I'll post some pics when they get back and I've had a chance to rework the shafts.

Will be looking forward to it. Thanks. Kim

gzig5

Well-Known Member

Please share what you need to do to the shafts when you get there. I assume the mounting holes need to be adjusted/elongated?Heads are still at PRH, I'll post some pics when they get back and I've had a chance to rework the shafts.

Please share what you need to do to the shafts when you get there. I assume the mounting holes need to be adjusted/elongated?

Mike gave me the numbers when he ran the calculations for my kit, I need to elongate the holes in the shafts by .100.

1.5 SM (prw) rockers and SM heads. 0.225 correction. A 1.6 rocker like most people run would require more.

(Sorry for posting in dribs and drabs, we've got people over so I'm slipping posts in as I can)

(Sorry for posting in dribs and drabs, we've got people over so I'm slipping posts in as I can)

Last edited:

Nice! Thanks for the pictures.

I’ll be talking to Mike shortly.

I’ll be talking to Mike shortly.

Rob, I did this with new rockers ,pushrods and shafts and picked up a tenth. Call me , it's pretty simple. The throttle response was night and day. Though with those "carby" things you use ,it may no be as dramatic.

Hey! What’s happening?!?!Rob, I did this with new rockers ,pushrods and shafts and picked up a tenth. Call me , it's pretty simple. The throttle response was night and day. Though with those "carby" things you use ,it may no be as dramatic.

I’ll give ya a call on this when I’m ready, and probably warmer. Between yourself and a excellent picture of the contact patch someone posted, I’m pretty much sold on this. The reconfigured set up has a milled deck surface on the block and heads (and intake...) with Hughes rockers on top of Edelbrock heads. This current set up is the most wacked thing I have ever put together. This geometry isn’t just off, it’s in outer space.

This is the old engine out of the E body.

yellow rose

Overnight Sensation

Hey! What’s happening?!?!

I’ll give ya a call on this when I’m ready, and probably warmer. Between yourself and a excellent picture of the contact patch someone posted, I’m pretty much sold on this. The reconfigured set up has a milled deck surface on the block and heads (and intake...) with Hughes rockers on top of Edelbrock heads. This current set up is the most wacked thing I have ever put together. This geometry isn’t just off, it’s in outer space.

View attachment 1715448623

This is the old engine out of the E body.

Where's all the W5 stuff?? I figured that would be on the stand and ready to go. Keep us posted on that build please.

looks like this with out the injectors?with Hughes rockers on top of Edelbrock heads. This current set up is the most wacked thing I have ever put together. This geometry isn’t just off, it’s in outer space.

-

Similar threads

- Replies

- 12

- Views

- 1K

- Locked

- Replies

- 2

- Views

- 571

- Replies

- 21

- Views

- 9K