[quote="Dart67";1969931155]Here are a couple of photos of the tool I made to measure/adjust the ride height on my 67 Darts.

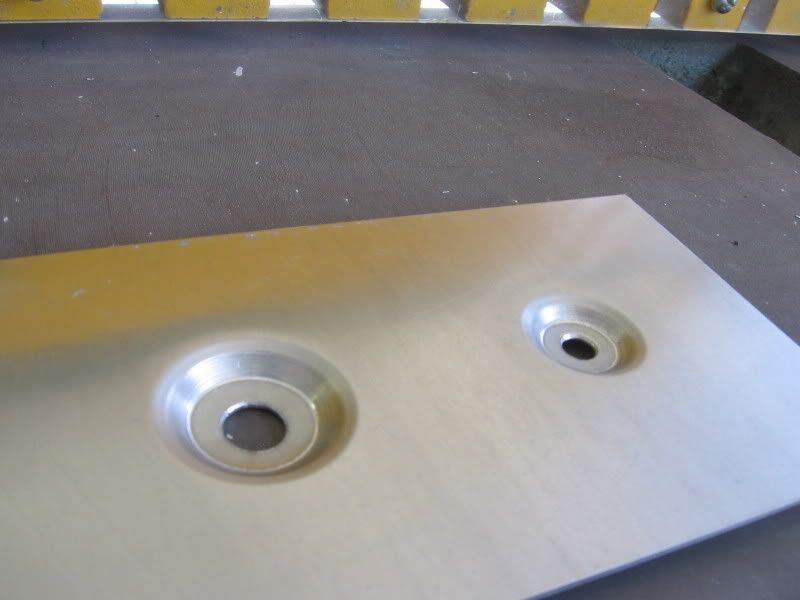

View attachment 1714609620

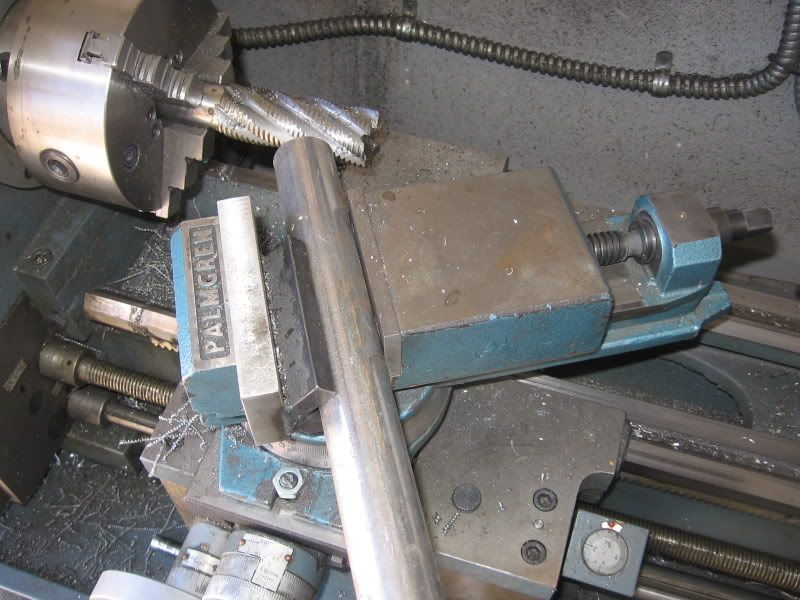

View attachment 1714609621

The tool is made of scrape that I had around the shop.

I used a 1/8" x 1 1/2" x 16" piece of flat strap for the base.

The uprigths are 1/4" black iron pipe spaced 13 7/8" center to center welded to the base.

The short one is 5" long.

The tall one is 7" long.

I tapped the top inside of each upright with a 3/8" x 16 tap.

I used two pieces of 3/8 x 16" all thread 4" long threaded into

each upright with a wing nut.

To measure the ride height, loosen each wing nut and turn each all thread rod down to clear the lower ball joint and the bottom of the torsion bar blade.

Then slide the tool under the lower ball joint and torsion bar blade and turn each rod until they touch the bottom of each and tighten the wing nut.

Slide the tool out and measure from the end of each all thread to the bottom of the strap.

The subtract the number to get your ride hieght.

Herb[/quote]

Nice job Herb. Measuring the ride height isn't easy to do accurately using a tape measure. Sure looks easy with your tool.