64Bones

Well-Known Member

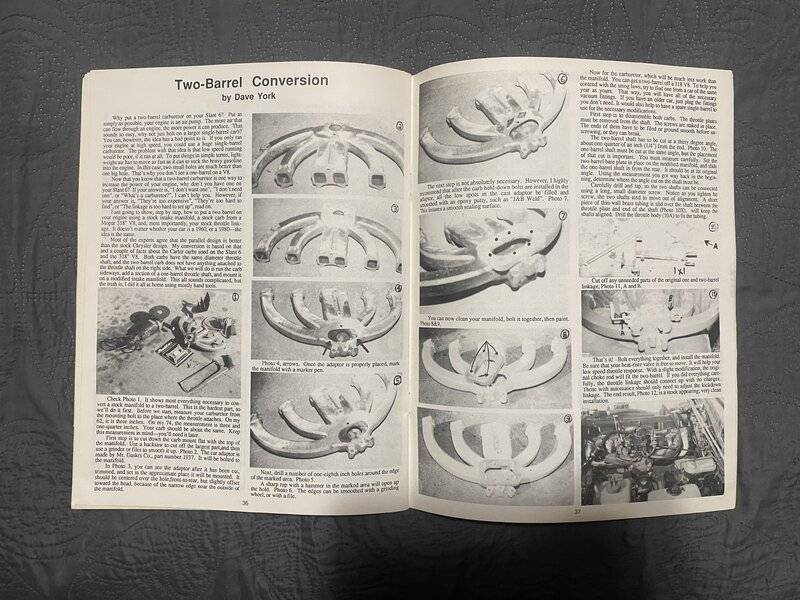

Early A Body Mopar 1962-1966 Two Barrel Conversion

1964 Plymouth Valiant 200 with a 225 slant six 1 barrel into a 2 barrel using the methods from a magazine article by Dave York

work done by the Slant Lords CC

located in the San Gabriel Valley, CA

1964 Plymouth Valiant 200 with a 225 slant six 1 barrel into a 2 barrel using the methods from a magazine article by Dave York

work done by the Slant Lords CC

located in the San Gabriel Valley, CA