Yes sir

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Block Head Flow Chart

- Thread starter TurboGLH

- Start date

-

Did you do any chamber work to go along with those larger valves?

I will post of a picture of the eddy head as the SM are bolted onto a block at this time....IMM did the work So i would assume that the chamber was reworked for the larger valve.

PRH

Well-Known Member

OOTB Ede RPM assembled head #60779.

4.00” bore, 28”, no tube on ex-

Lift———in/ex

.100—— 64/49

.200——126/97

.300——185/133

.400——227/156

.500——250/166

.600——253/169

4.00” bore, 28”, no tube on ex-

Lift———in/ex

.100—— 64/49

.200——126/97

.300——185/133

.400——227/156

.500——250/166

.600——253/169

Cast SM flowed by @pittsburghracer

Lift—- in/ex

.100— 55/37

.200—131/100

.300—185/142

.400—235/164

.500—240/176

.600—246/180

.700— 259/185

Lift—- in/ex

.100— 55/37

.200—131/100

.300—185/142

.400—235/164

.500—240/176

.600—246/180

.700— 259/185

PRH

Well-Known Member

CNC’d SM head-

OOTB vs valve job with back cut valve, and minor blend-

28” test pressure, 4” bore:

A-OOTB

B-Valve job

Intake ports:

Lift———A/B

.100— 64/67

.200—126/132

.300—166/191

.400—206/232

.500—242/262

.600—271/275

.700—284/281

Exhaust ports:

Lift—— A/B

.100— 49/55

.200— 95/102

.300—132/137

.400—163/170

.500—179/188

.600—187/192

.700—190/194

OOTB vs valve job with back cut valve, and minor blend-

28” test pressure, 4” bore:

A-OOTB

B-Valve job

Intake ports:

Lift———A/B

.100— 64/67

.200—126/132

.300—166/191

.400—206/232

.500—242/262

.600—271/275

.700—284/281

Exhaust ports:

Lift—— A/B

.100— 49/55

.200— 95/102

.300—132/137

.400—163/170

.500—179/188

.600—187/192

.700—190/194

Last edited:

PHR, so can we assume an untouched CNCed head would flow 250 or so? Thanks. Kim

See the chart on page 1. I think the cnc head is there.PHR, so can we assume an untouched CNCed head would flow 250 or so? Thanks. Kim

PHR, so can we assume an untouched CNCed head would flow 250 or so? Thanks. Kim

See the chart on page 1. I think the cnc head is there.

As of today the chart is up to date with every post that had flow data.

I had to give up on graphing all the numbers, too many to be manageable, but if you open the chart on a computer it's easier to see all the data

PRH

Well-Known Member

PHR, so can we assume an untouched CNCed head would flow 250 or so? Thanks. Kim

The “OOTB” test(coulumn A) is just as it came ootb.

That is the CNC ported head.

The OOTB unported head is in the 250 range(on my bench).

The “OOTB” test(coulumn A) is just as it came ootb.

That is the CNC ported head.

The OOTB unported head is in the 250 range(on my bench).

And probably a little turbulent too. At least it was on mine at .600-.700.

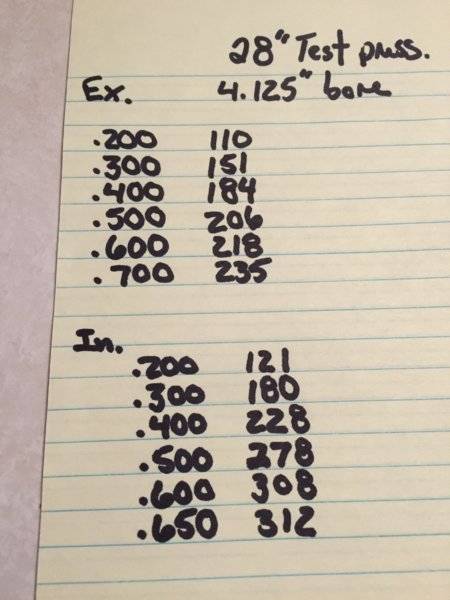

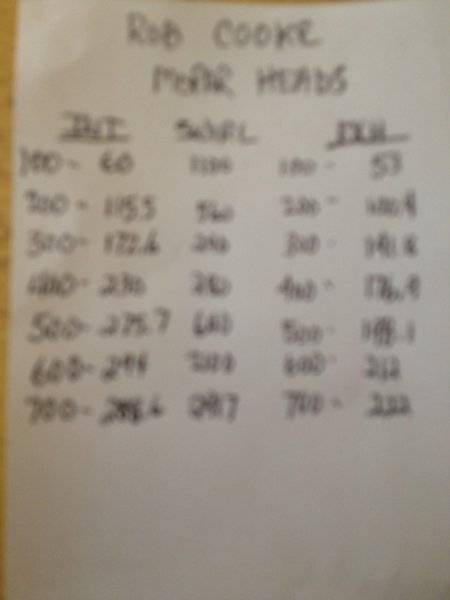

Because @yellow rose asked...

My (Long Stalled) W5 project. Ti 2.08/1.60 valves.

Heads ported by Brett Miller (Thank you) flower on a 4.125 bore.

Re flow checked by ElSasser Racing Engines on a 4.03 bore. (Which is closer to what I’ll actually have unless Santa Clause drops off a Ritter or MP race block.)

Brett took them until one of the ports gave up the ghost and broke through. Epoxy was used in 1 port. No sense in going any more forward.

Looking to use my Ultradyne NF64/ F69 SFT in a stroker.

My (Long Stalled) W5 project. Ti 2.08/1.60 valves.

Heads ported by Brett Miller (Thank you) flower on a 4.125 bore.

Re flow checked by ElSasser Racing Engines on a 4.03 bore. (Which is closer to what I’ll actually have unless Santa Clause drops off a Ritter or MP race block.)

Brett took them until one of the ports gave up the ghost and broke through. Epoxy was used in 1 port. No sense in going any more forward.

Looking to use my Ultradyne NF64/ F69 SFT in a stroker.

Last edited:

Just some eye candy....

That’s sure is nice parts Rob. Kim

I've added a second page to the chart with the heads sorted by type, it was getting fairly long and required a bunch of scrolling to the side to see everything.

Looking for feedback one vs the other, or any changes that would help with making it easier to view and compare.

Again, best viewed on a PC, phone screens with always be a limit, but I know lots of people use their phone first, so feedback based on mobile viewing is appreciated too.

Looking for feedback one vs the other, or any changes that would help with making it easier to view and compare.

Again, best viewed on a PC, phone screens with always be a limit, but I know lots of people use their phone first, so feedback based on mobile viewing is appreciated too.

Last edited:

stixx

Well-Known Member

Great job Turbo! I also like the second chart with the heads sorted by type, makes it a bit easier to navigate around.

You always will have to scroll when you want to compare heads...

You always will have to scroll when you want to compare heads...

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Really sweet heads.

They had way more in them down low to give...but not everyone knows how to do it.

Gonna use a .650 roller cam?

Ultradyne NF lobe (Harolds) NF64/NF/69

The cam card is not in front of me, so, IIRC, .620/.640 lift.

The heads actually have my W2 rockers on top.

I’d like to get a Jesel set up in a 1.6 rocker.

The cam card is not in front of me, so, IIRC, .620/.640 lift.

The heads actually have my W2 rockers on top.

I’d like to get a Jesel set up in a 1.6 rocker.

SwedishViking

Well-Known Member

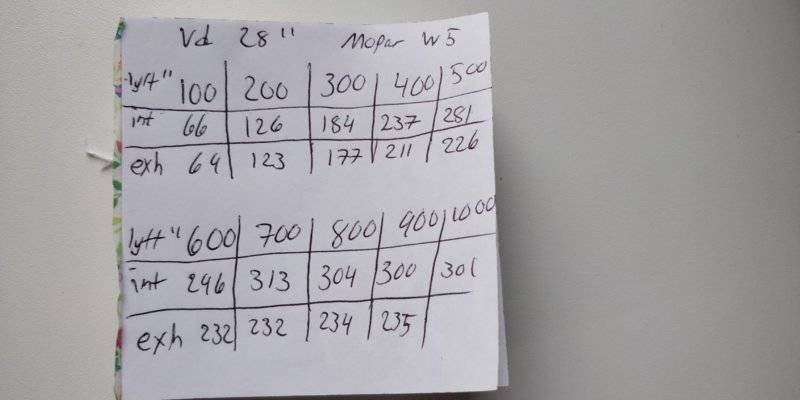

Got my w5s back today, was hoping for better flow numbers.

Do you know in what bore size the head tested at?Got my w5s back today, was hoping for better flow numbers.

Was there any mention of the port going turbulent?

Did the head require epoxy?

Did you mention your valve sizes?

I wouldn’t be to upset. That’s enough flow right there for some serious HP. Plus the head ports are still moving some pretty good air past the peak. If you were so inclined to continue lifting the valve, you will still be making more power.

The only 2 drawbacks to the W5 head is the possible poor casting ether turning the head into water sprinklers (leaking) and/or not being able to be ported out to some of the reported superb flow numbers that have been done. Then the expensive rocker arm set up even though it is seriously superior to other offerings, which has excellent dividends, it’s just pricey as I said. Though if it is a race car, it would be worth it. Street car? Ehhhh, owner’s call.

Again, I understand being disappointed with the flow results but they show well enough for some *** kickin.

They sure are pretty! It's fun to look down the intake ports and not have to look past the pushrod pinch!Do you know in what bore size the head tested at?

Was there any mention of the port going turbulent?

Did the head require epoxy?

Did you mention your valve sizes?

I wouldn’t be to upset. That’s enough flow right there for some serious HP. Plus the head ports are still moving some pretty good air past the peak. If you were so inclined to continue lifting the valve, you will still be making more power.

The only 2 drawbacks to the W5 head is the possible poor casting ether turning the head into water sprinklers (leaking) and/or not being able to be ported out to some of the reported superb flow numbers that have been done. Then the expensive rocker arm set up even though it is seriously superior to other offerings, which has excellent dividends, it’s just pricey as I said. Though if it is a race car, it would be worth it. Street car? Ehhhh, owner’s call.

Again, I understand being disappointed with the flow results but they show well enough for some *** kickin.

I agree and that’s what makes these heads (W2/5) worth it. A larger unobstructed port window (Or a door to allow more people in) than the LA head and it’s replacements.They sure are pretty! It's fun to look down the intake ports and not have to look past the pushrod pinch!

Like Swedish Viking, I was hoping for more cfm to help out a large(r) cubic inch engine.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Choose the cam wisely, the exhaust is frisky .100-.300ish ,watch the overlap.

Numbers are not bad. Fatter down low? Could be. But they are good numbers.

Good flow rate as it lifts.

Its flowing below 180cfm @.300 that would be not so good.

SwedishViking

Well-Known Member

The flowing was done with a bore of 4,10 and with 2" exhaustpipe.

Well we will see what kind of cam it gets. Roller or flat.

Well we will see what kind of cam it gets. Roller or flat.

I have a set of Eddy Magnum heads that were ported looks like 10 yrs ago...4 files...stock intake...stock exhaust and ported intake and ported exhaust...

These were done in Carson City NV.

These were done in Carson City NV.

Attachments

I wish I could open these attachments. What’s so hard to just post up the numbers

-

Similar threads

- Replies

- 16

- Views

- 8K

- Replies

- 22

- Views

- 21K