I never questioned you. As long as the "antiquated garbage" as you call it is in good shape and installed correctly, there won't be an issue.It can happen because it did

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

U-joint on steering shaft: float or bolt down?

- Thread starter Abodysrule

- Start date

-

replicaracer43

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 6,051

- Reaction score

- 7,867

Never underestimate a person's ability to "out smart" oem engineers who designed a coupler that does everything it should and lasts 50 years.I never questioned you. As long as the "antiquated garbage" as you call it is in good shape and installed correctly, there won't be an issue.

Right, but we're talking about a U-joint, the splined end coming off the steering box splines if you don't use the set screw. My point is, on my system at least, there is only at most 2mm of movement on that axis, and nearly an inch of spline contact, so no way it'll slip off if you let it slide on the splines, like a driveshaft yolk on a tranny output shaft.

I think that is a great idea, put it together and run it like you stole it.My point is, on my system at least, there is only at most 2mm of movement on that axis, and nearly an inch of spline contact, so no way it'll slip off if you let it slide on the splines, like a driveshaft yolk on a tranny output shaft

Just be sure you have a few million dollars liability insurance, and a get out of jail free card.

If it fails you will be negligently liable since you did not install it per the manufacturers instructions.

Get a mechanical engieer to look over your design.

mopar head

Well-Known Member

Those old Chrysler engineers were pretty smart fellers, I`ll never fix what ain`t broke.

I did use u-joints on my car I engineered. The barracuda will be left alone.

Funny, my 67 uses a small tapered pin to hold the shoes in the coupler. I need to reinstall that some day

I did use u-joints on my car I engineered. The barracuda will be left alone.

Funny, my 67 uses a small tapered pin to hold the shoes in the coupler. I need to reinstall that some day

IIRC collapsible columns started in 70The column on the later cars is collapseable. Those of us with early cars die like men.

67 has collapsible columnIIRC collapsible columns started in 70

"Impact- Absorbing Steering Column"

Last edited:

Thanks, Brooks! I knew the early cars didn't have them.IIRC collapsible columns started in 70

I stand corrected, thank you

There are many reasons the shaft or column can move back. Why take the chance. All manufactures allow for vibration. Some use rag joints. But all are held securely to the splines on the steering box.OK, I have a data point. Luckily, my pot coupler was powder coated, so the wear pattern inside where the shoes rub was very easy to see/measure, all four tracks are 23 mm long. The edge of the shoe that rubs there is 21 mm long. 23 mm - 21 mm = 2 mm So, that means the flex my system was seeing at most 2mm up and down the steering axis (more likely 1 mm up and down from a central shoe position). No way those splines would pull out of the U-joint.

I'd be curious to see if anyone else has made this measurement and what the numbers look like.

View attachment 1716069960

View attachment 1716069961

They must have a reason for this. Even the coupler has a pin to prevent it from coming apart.

Do what you want. See you in the Ditch if you lose connection to your " Borgeson box" LOL. Just tossed one of them in the scrap metal bin last week. My 53 6400 Chevy Wrecker steered better, And easier when loaded heavy. The numbers on the door call me if you need ditch removal service.

thesiren74

Well-Known Member

Have one on my Duster for 4 years works so much better and not sloppy.Not in the early cars. The factory coupler is the only thing that allows any fore and aft movement. Replace it with a U joint and now you have no movement there at all and have extra vibration. No thanks.

thesiren74

Well-Known Member

Yeah because nothing got better overtime.Never underestimate a person's ability to "out smart" oem engineers who designed a coupler that does everything it should and lasts 50 years.

thesiren74

Well-Known Member

That's the pin that came out and put the car in the ditch.Those old Chrysler engineers were pretty smart fellers, I`ll never fix what ain`t broke.

I did use u-joints on my car I engineered. The barracuda will be left alone.

Funny, my 67 uses a small tapered pin to hold the shoes in the coupler. I need to reinstall that some day

mopar head

Well-Known Member

Then the collapse shafts were severely compromised. Even with the plastic shear pins sheared you will not just slide the shafts by hand, mine hasn`t moved in 20 years, but some day I`ll get around to putting that tiny tapered pin back in...That's the pin that came out and put the car in the ditch.

If your original coupler was sloppy, it had something wrong with it.Have one on my Duster for 4 years works so much better and not sloppy.

There are splines that are DESIGNED to slide and ones that are not. The ones on the coupler are NOT designed to slide.

WARNING. IM BEING A BIT OF A DICK WITH THE FOLLOWING.

As for a pin breaking and causing the coupler to come loose....

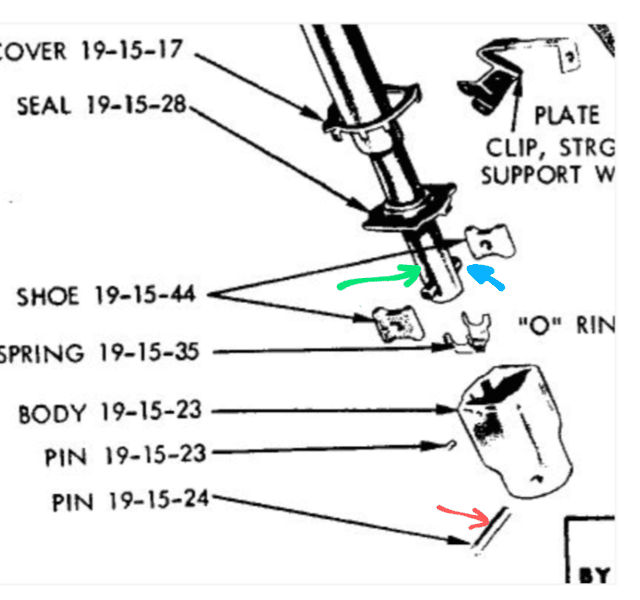

Green arrow, the shaft is flat

Blue arrow, the pin the sliders are held on with

Red arrow, the roll pin that keeps the splined shaft from coming out of the steering input shaft

To loose steering one or more of the following would have to happen.

My theories about the misfortune that ended in a ditch.

Dickish rant over.

WARNING. IM BEING A BIT OF A DICK WITH THE FOLLOWING.

As for a pin breaking and causing the coupler to come loose....

Green arrow, the shaft is flat

Blue arrow, the pin the sliders are held on with

Red arrow, the roll pin that keeps the splined shaft from coming out of the steering input shaft

To loose steering one or more of the following would have to happen.

- The roll pin (red) would have to come out AND the coupler would have to move up 1 plus inches.

- The pin (blue) would have to shear and the column would need to collaps 3 plus inches.

- If the pin (blue) sheared but the column did not collapse 3 plus inches the flats (green) on the shaft and the flats of the sliders would not allow the steering shaft to turn and not turn the coupler

- The pin (blue) is trapped by the coupler, it can not just fall out.

- The roll pin (red) could be missing and as long as the steering shaft did not move 1 plus inches the splines would still be engaged.

My theories about the misfortune that ended in a ditch.

- The coupler was not assembled correctly

- The coupler seal was missing / bad and it filled with water and over many years rusted the insides to nothing

- The roll pin was missing / rusted to nothing and the steering shaft had been collapsed in the past and was not pulled back far enough

- The driver lost control ended in a ditch and after finding broken steering parts blamed that rather then taking responsibility for his actions

Dickish rant over.

replicaracer43

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 6,051

- Reaction score

- 7,867

Your not being a dick at all, sometimes it takes pictures, (and even crayons) to explain facts to people who think a Chinese u joint is a "upgrade" Those type of people should NOT be working on cars.There are splines that are DESIGNED to slide and ones that are not. The ones on the coupler are NOT designed to slide.

WARNING. IM BEING A BIT OF A DICK WITH THE FOLLOWING.

As for a pin breaking and causing the coupler to come loose....

Green arrow, the shaft is flat

Blue arrow, the pin the sliders are held on with

Red arrow, the roll pin that keeps the splined shaft from coming out of the steering input shaft

To loose steering one or more of the following would have to happen.

The following would alloy the driver to maintain control if there was some pin failure

- The roll pin (red) would have to come out AND the coupler would have to move up 1 plus inches.

- The pin (blue) would have to shear and the column would need to collaps 3 plus inches.

- If the pin (blue) sheared but the column did not collapse 3 plus inches the flats (green) on the shaft and the flats of the sliders would not allow the steering shaft to turn and not turn the coupler

- The pin (blue) is trapped by the coupler, it can not just fall out.

- The roll pin (red) could be missing and as long as the steering shaft did not move 1 plus inches the splines would still be engaged.

My theories about the misfortune that ended in a ditch.

- The coupler was not assembled correctly

- The coupler seal was missing / bad and it filled with water and over many years rusted the insides to nothing

- The roll pin was missing / rusted to nothing and the steering shaft had been collapsed in the past and was not pulled back far enough

- The driver lost control ended in a ditch and after finding broken steering parts blamed that rather then taking responsibility for his actions

View attachment 1716070371

Dickish rant over.

72Duster440

Well-Known Member

And Pin 19-15-23 keeps the shoes inside of the coupler body.

-