I always seem to have seen to have difficulty getting my valve covers to seal well on my 273. What do you guys like...and do you use gasket sealer?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve cover gasket opinion...Cork vs Rubber

- Thread starter Michael Brisebois

- Start date

-

both will work, I've used both. I prefer cork with a thin coat of Indian Head shellac. I take them off and on many times without buying new. Trick is don't overtighten.

nm9stheham

Well-Known Member

I'll use either but prefer rubber. RTV on the cover side. Lightly peening the flange hole areas flat first is one of the big keys to a good seal, as well and juuust snugging them down, not torquing them to any large degree. Looks like I just said the same thing as WR above!

Post a couple of pictures of the valve covers & we might be able to see why you have a sealing problem.

I use the cork with the impregnated rubber on mine. Yes, like mentioned, make sure the gasket rail is flat especially around the bolt holes and don't over torque.

I've always had decent results with cork.

All mentioned above, move around the covers with a small hammer and make sure all holes are flat, clean cover well and apply some RTV (doesn't require gobs) install gasket on cover and let set up overnight allowing for the gasket to "stick" to the cover.

Make sure surface on the head is clean and there isn't old gasket material stuck.

As a final step I use my finger and smear a little grease all the way around the gasket where it mates to the head, reason being if you need to remove the covers the grease helps keep the gasket from sticking to the head.

DO NOT over tighten.

I have removed covers and reused the gasket in place several times without a leak. YMMV

All mentioned above, move around the covers with a small hammer and make sure all holes are flat, clean cover well and apply some RTV (doesn't require gobs) install gasket on cover and let set up overnight allowing for the gasket to "stick" to the cover.

Make sure surface on the head is clean and there isn't old gasket material stuck.

As a final step I use my finger and smear a little grease all the way around the gasket where it mates to the head, reason being if you need to remove the covers the grease helps keep the gasket from sticking to the head.

DO NOT over tighten.

I have removed covers and reused the gasket in place several times without a leak. YMMV

R4Sedan

Larry

I use the re-useable rubber/steel ones. Love'em. Never a problem.

dibbons

Well-Known Member

I use rubber glued to the valve cover with yellow 3M weatherstrip adhesive, little studs in the cylinder heads, and nuts with captive lock washers.

Tighten gently with a little screwdriver type handle and a 7/16" socket. Valve cover can be removed and replaced whenever (for valve adjustment, etc.)

Another good idea is washers that spread the load (last two fotos). You will need all the help you can find.

Tighten gently with a little screwdriver type handle and a 7/16" socket. Valve cover can be removed and replaced whenever (for valve adjustment, etc.)

Another good idea is washers that spread the load (last two fotos). You will need all the help you can find.

Marcohotrod

Well-Known Member

I use oil on the head side, and with sheetmetal covers adhesive on the cover side. I had some old McCord gaskets that were cork/rubber made from 4 pieces glued together - they sucked and fell apart. with cast aluminum covers I run "black rubber" cheap fel pro gaskets - retorque - no leaks.

67dodgedartconv

Well-Known Member

I use the re-useable rubber/steel ones. Love'em. Never a problem.

I use the same, think they were mopar performance. Never had a problem either.

I've had the same set of rubber & steel sandwich gaskets on the race car for 9 years with no problems. Keep in mind, I have a solid lifter roller cam in the car & routinely pull the covers to check the lash.

LJ67barracuda340

Well-Known Member

Mopar Performance P5249581AB - Mopar Performance Valve Cover Gaskets

the last gasket you'll need. had mine off and on dozen times, not a drop.

the last gasket you'll need. had mine off and on dozen times, not a drop.

No leaks here.

Edelbrock Valve Cover Gaskets 7592

Edelbrock Valve Cover Gaskets 7592

pntastar69

Well-Known Member

Mopar Performance P5249581AB - Mopar Performance Valve Cover Gaskets

the last gasket you'll need. had mine off and on dozen times, not a drop.

Yep, dems the ones although costly. No sealant needed on stock stamped steel vc's, tighten and go, no leaks.

abodyjoe

Well-Known Member

i love these.. Mopar Performance Valve Cover Gaskets P5249581AB

pntastar69

Well-Known Member

Do a search in the small block forum, valve cover gaskets. Lots o info there. Here's one from my experience with leaks.

Sealing Stamped Small Block Valve Covers – Grrr

Sealing Stamped Small Block Valve Covers – Grrr

I bet the Dodge store has them cheaper than Summit too.

Mopar Performance P5249581AB - Mopar Performance Valve Cover Gaskets

the last gasket you'll need. had mine off and on dozen times, not a drop.

Yep, dems the ones although costly. No sealant needed on stock stamped steel vc's, tighten and go, no leaks.

383Scampman

Well-Known Member

Save yourself a lot of grief and get Moroso blue gaskets . guaranteed not to leak . Torque them to 8-12 ft.lbs. Most v.c.gasket leaks come from overtightening .

dibbons

Well-Known Member

Quoting the post made before this one #18 above: "Torque them to 8-12 ft.lbs. Most v.c.gasket leaks come from overtightening."

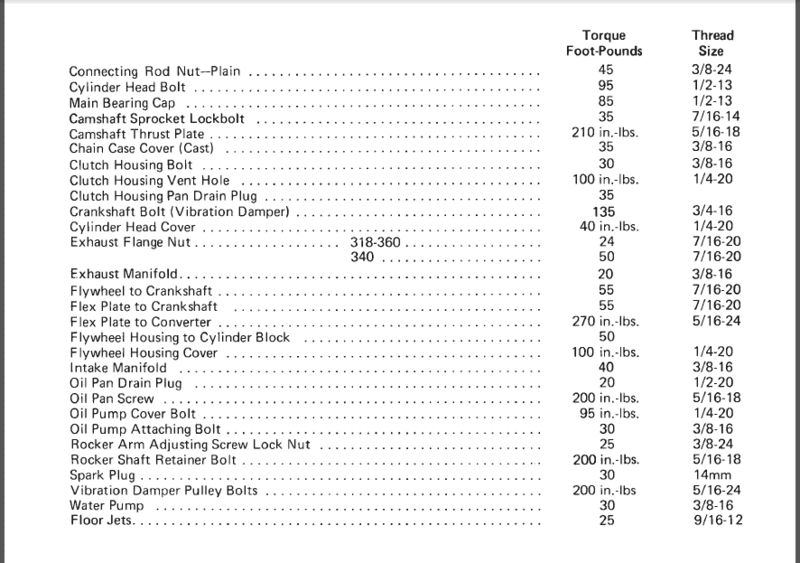

Please be careful, 1972 Chrysler Factory Service Manual (page 9-93) lists small block torque specs for "cylinder head covers" (valve covers) as 40 INCH/LBS which works out to only 3.33 ft/lbs (40 divided by 12 = 3.33). That's why I only use a screwdriver handle adapted to use a small socket.

Please be careful, 1972 Chrysler Factory Service Manual (page 9-93) lists small block torque specs for "cylinder head covers" (valve covers) as 40 INCH/LBS which works out to only 3.33 ft/lbs (40 divided by 12 = 3.33). That's why I only use a screwdriver handle adapted to use a small socket.

Last edited:

pntastar69

Well-Known Member

Save yourself a lot of grief and get Moroso blue gaskets . guaranteed not to leak . Torque them to 8-12 ft.lbs. Most v.c.gasket leaks come from overtightening .

Tried them, they leaked during engine priming.

383Scampman

Well-Known Member

I have them on my 383 and they don't leak with cast valve covers . rubber leaks and cork drys up and sticks to everything

LJ67barracuda340

Well-Known Member

hey Steve,,what is the Dodge store? are you meaning the dealerships.?I bet the Dodge store has them cheaper than Summit too.

[QUOTE="Michael Brisebois]I always seem to have seen to have difficulty getting my valve covers to seal well on my 273. What do you guys like...and do you use gasket sealer?[/QUOTE]

As weird as this sounds, the 3'rd 'short fuse' 273 (built

circa '79) leaked from the right rear and left center !!!

--- Light Bulb ---

File down the head to cover surfaces...

Michael Brisebois

I look forward to Your Pictures.

As weird as this sounds, the 3'rd 'short fuse' 273 (built

circa '79) leaked from the right rear and left center !!!

--- Light Bulb ---

File down the head to cover surfaces...

Michael Brisebois

I look forward to Your Pictures.

-