If it really is 4 that is too small

You need to run some tests, I've posted this numerous times.

1.....Grounding. The battery neg. post, the car (in this case unibody) and the engine block and alternator all need to be as close as the exact same voltage as possible

Here's how you check. Make this test with engine running, battery up and normalized, and engine warm. This is because the voltage regulator has temperature compensation. Make this test first with all accessories off, and again with lights, heater, whatever loads you and put on turned on. In your case, you will have to make a long extension for your meter

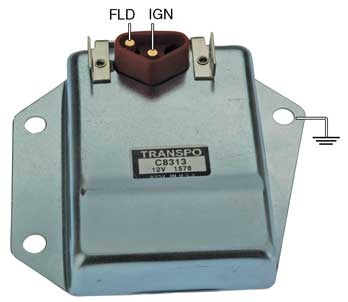

Clamp one probe of your multimeter to the battery NEG clamp. It would be better if you could have a helper stab the probe right into the top of the post itself. With the meter set on low DC volts, stab the other probe into the VR mounting flange. Be sure to stab through any rust, chrome, paint.

You are hoping for a very low reading, the lower the better, zero is perfect. More than about .3v (three tenths of a volt) means you have a ground problem and need to do some work.

2....Next check voltage drop in the hot side of the harness. To do this, hook one probe of your meter to the POS post of the battery. Again a helper stabbing the probe into the POS post would be best, but as close to the post as you can get is OK. With the engine NOT running, but with the key in the RUN position, hook the other lead to as close as you can get to the VR "ign" connection, which is the "IGN" run wire in the engine bay. This is probably going to be either the high side of the ballast, or the blue field wire on the alternator. Once again, you are hoping for a very low reading

With "stock" wiring, you would have going through the following circuit path............

Battery.......starter relay......fuse link.......through the bulkhead connector........ammeter connections........through the ammeter............. welded harness splice..........ignition switch connector........through the switch........back out the switch connector.........back out the bulkhead.......and to the switched ignition loads under the hood..........to the VR

Lots of stuff there, but the biggest suspects are the bulkhead connector, the switch connector and the switch itself.

ANY added V drop will ADD to charging voltage. This means, example, that if you have a V reg that is trying to regulate at 14.2, and you have .2 drop in the ground and another .4 drop in the ignition harness, you now have 14.2 + .2 + .4 so now the battery will charge at 14.8V instead of 14.2

3....It's also very very important with a trunk mount battery to pay attention to GROUNDING in the system, because with a front mount battery, the heavy starter current is almost always grounded right to the block. With a trunk mount battery grounded to the body, you must use large enough cables, and get the engine / trans combo grounded well enough that the thing will crank.

You can measure THAT too!!!!

Clip your meter to the battery neg post, and to the engine block and crank the engine long enough for the meter to settle down, say, 4 seconds, and read the meter during cranking. How much voltage you read? That is the voltage drop you have through all the connections, cables, and the body, to the engine block.

4.....Same deal on the "hot" side

Carefully clip your meter to the "big" battery stud on the starter, or maybe the alternator stud, and run you meter extension probe back to the battery "hot" post. Again crank the engine, and read the meter while cranking. This is the drop across your no4 cable.

Do this with engine warm, as it takes more "juice" to do so, and you get a better picture of what is required