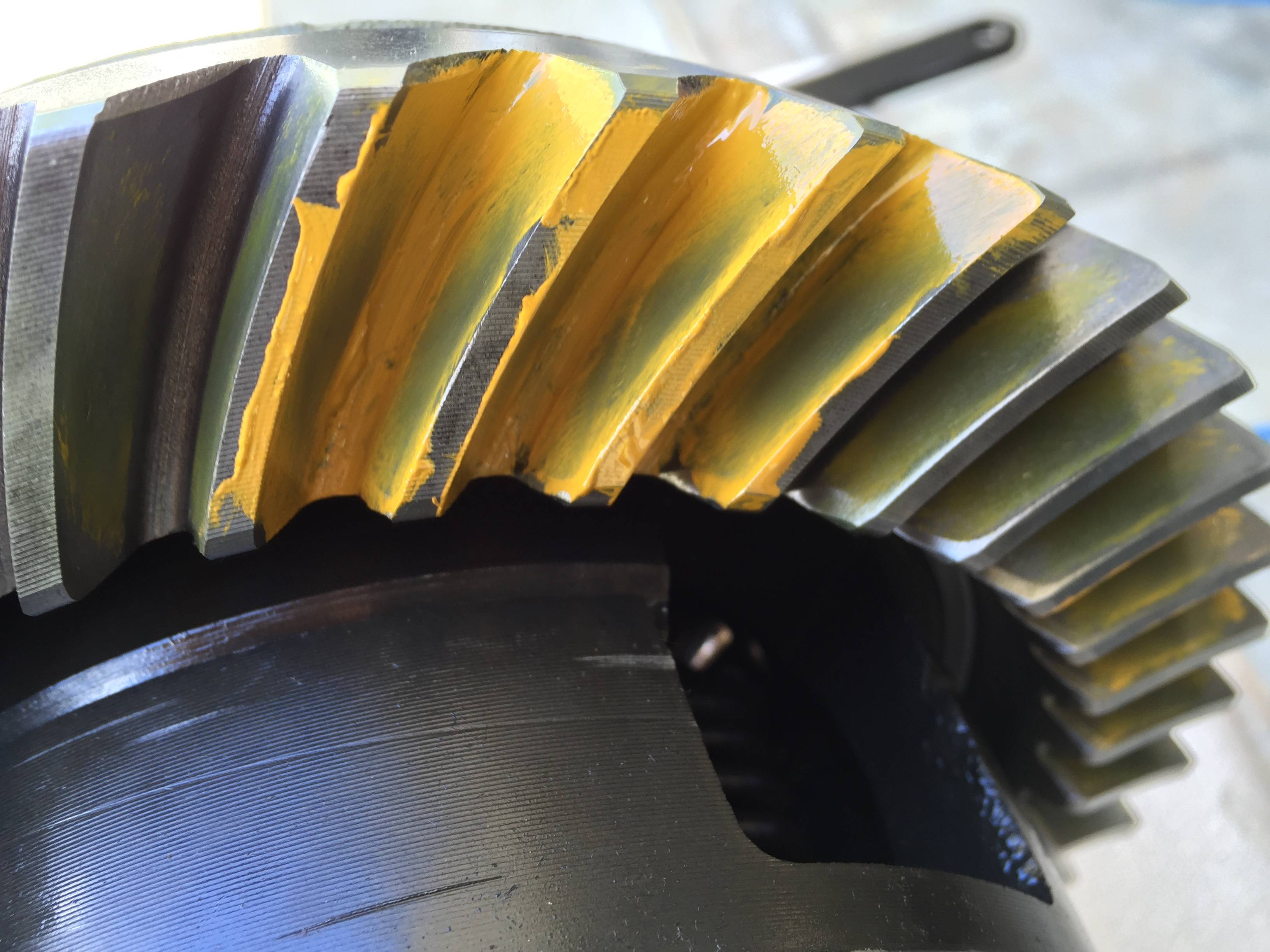

Swapping gears in my 742 case! Pulled the center and removed the 4.56 gears. Installed new koyo pinion races and new 3.55 pinion with koyo setup bearing. Ran the pattern and got the pictured. Looked good to me. So I do the pinion freeze and bearing heat and it dropped right on! Happy and go for re-assembly and darn the pinnion is dragging on the center section! What happened? I recheck my backlash and it still hits. So I make the descion to press off the pinion bearing thinking there is a race issue. I put the set-up bearing back on and still have interference. I removed the races and confirmed they were seated and no obstrutions. Installed new races again then reduced the shim by 10 thousands and get a good pattern. I am concerned that only reducing by .010 might lead to contact at temp. Opinions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did I do wrong?

- Thread starter 1969383S

- Start date

-

RustyRatRod

Caput villa stultus

Looks a little deep to me. I never in my life have heated a pinion bearing or froze a pinion. It's not THAT bad of a press fit. Hopefully you didn't damage anything there.

Doctor Diff Gears Marked for .095.

That is what I started at (.094) and thought it was real close with minor backlash change. What most surprised me after installing the real bearing of the same manufacture that it was contacting the center section. Thought I would save some effort and learn a new trick with the freeze/heat method. It seemed to be so easy!!! Not happy on final assembly though! Pressed off the bearing and will not re-use it even though it looks fine. Dropped the pack down to .084 and have basically the same pattern. Is this enough for heat expansion??? I am a concerned! I have a new bearing ready to go but do not want to do this again!!

That is what I started at (.094) and thought it was real close with minor backlash change. What most surprised me after installing the real bearing of the same manufacture that it was contacting the center section. Thought I would save some effort and learn a new trick with the freeze/heat method. It seemed to be so easy!!! Not happy on final assembly though! Pressed off the bearing and will not re-use it even though it looks fine. Dropped the pack down to .084 and have basically the same pattern. Is this enough for heat expansion??? I am a concerned! I have a new bearing ready to go but do not want to do this again!!

RustyRatRod

Caput villa stultus

I don't know. That seems like it would be mighty close to the carrier. Are those contact marks I see on it in the first picture? The dotted lines?

No.I don't know. That seems like it would be mighty close to the carrier. Are those contact marks I see on it in the first picture? The dotted lines?

It would not turn basically and after attempting re-adjusting backlash I could see some half semi-circles where it dragged. I did not take pics of that.

Close is my concern. I am going to pull a .020 shim and replace with an .010 shim and re-pattern because of this concern. Will post up the change Tomorrow night. That will put me at .074 total.

RustyRatRod

Caput villa stultus

Maybe contact Cass at Dr Diff and see what he says. Seems kinda screwy to me.

Maybe contact Cass at Dr Diff and see what he says. Seems kinda screwy to me.

Talked to Cass after I got the Gears and he said to start at 095. Yes it is way screwy to get that pattern for it to change that much. Belief me I was loosing some sleep last Sunday over it. For a minute I thought maybe I did not tighten the carrier caps or something, but proved that in my mind after pressing the bearing off and starting over.

Maybe contact Cass at Dr Diff and see what he says. Seems kinda screwy to me.

By the way, thanks for the responses! Seems like a simple thing I have done lots of times short of the freeze/Heat trick. Maybe if reducing another 10 gives a close pattern I will press the bearing the old fashioned way. Just nervous about contact with the carrier at this point!

Just to double check your assembly, You said it set up good with the checking bearing but when you press the new pinion bearing on the pinion face was hitting the carrier? Are you sure the new bearing was pressed ALL the way on?

john-9

Well-Known Member

Swapping gears in my 742 case! Pulled the center and removed the 4.56 gears. Installed new koyo pinion races and new 3.55 pinion with koyo setup bearing. Ran the pattern and got the pictured. Looked good to me. So I do the pinion freeze and bearing heat and it dropped right on! Happy and go for re-assembly and darn the pinnion is dragging on the center section! What happened? I recheck my backlash and it still hits. So I make the descion to press off the pinion bearing thinking there is a race issue. I put the set-up bearing back on and still have interference. I removed the races and confirmed they were seated and no obstrutions. Installed new races again then reduced the shim by 10 thousands and get a good pattern. I am concerned that only reducing by .010 might lead to contact at temp. Opinions?

View attachment 1714929574

View attachment 1714929575

Had this same issue last year with the pinion gear contacting the carrier with a fellows 8-3/4 --- tranny shop could not figure it out ( they ruined his original case trying to make it work ) and it ended up with me to sort out --- gears were Doctor Diff brand 3.55 for 742 case --- what I did was remove .030 off the pinion face ,,, this does not compromise the gear or contact pattern at all --- no issues after that, gears set up ok ( with .095 shim ) with plenty of clearance for the carrier .

Just to double check your assembly, You said it set up good with the checking bearing but when you press the new pinion bearing on the pinion face was hitting the carrier? Are you sure the new bearing was pressed ALL the way on?

Yes, My thought exactly but confirmed the bearing was all the way down with feeler gauges measured at .094. It did not rub at 1st set-up WTH.

That's why I knocked out the races and confirmed all was good there. No burrs or anything so I put new ones back in and removed the bearing to start over.

Had this same issue last year with the pinion gear contacting the carrier with a fellows 8-3/4 --- tranny shop could not figure it out ( they ruined his original case trying to make it work ) and it ended up with me to sort out --- gears were Doctor Diff brand 3.55 for 742 case --- what I did was remove .030 off the pinion face ,,, this does not compromise the gear or contact pattern at all --- no issues after that, gears set up ok ( with .095 shim ) with plenty of clearance for the carrier .

Interesting!!

Wonder if the contact with the carrier was there from the start? Mine seemed to pattern fine at 095 with no clearance issue on first attempt. What I do not understand is why it changed after final install of the pinion bearing.

Kinda calls into question weather your checking bearing and the new bearing were of the same dimensions?

fishy68

Tyr Fryr's Inc.

Kinda calls into question weather your checking bearing and the new bearing were of the same dimensions?

My thoughts too. I'd double check the bearings to see if the new bearings and races are correct. If you have a depth mic or pinion set up gauge you can see if both the checking bearings and new bearings provide the same pinion depth. If not something if wrong. Most likely a problem with the rear bearing or race would be my guess

john-9

Well-Known Member

Interesting!!

Wonder if the contact with the carrier was there from the start? Mine seemed to pattern fine at 095 with no clearance issue on first attempt. What I do not understand is why it changed after final install of the pinion bearing.

with the new bearing races installed into the case ,,, I use set up bearings for the initial assembly to get the correct gear pattern -- I always do a repeat set up using the New head bearing to double check the gear pattern ,,, and sometimes , not always, there are minor changes to the pattern requiring a slight shim change ,,,.then on to final assembly of all components .

this leads me to believe that there are slight dimensional differences in bearing cones and races.

Thanks for all the responses!

I pressed the old bearing off the 4.56 gear and checked dimensions on it, the setup up bearing, the new one I put on with heat/freeze and the 2nd new one I ordered to replace the first one I had to remove. No more than 001 difference. The new and set-up are all koyo HM803149N, the original is a Bower.

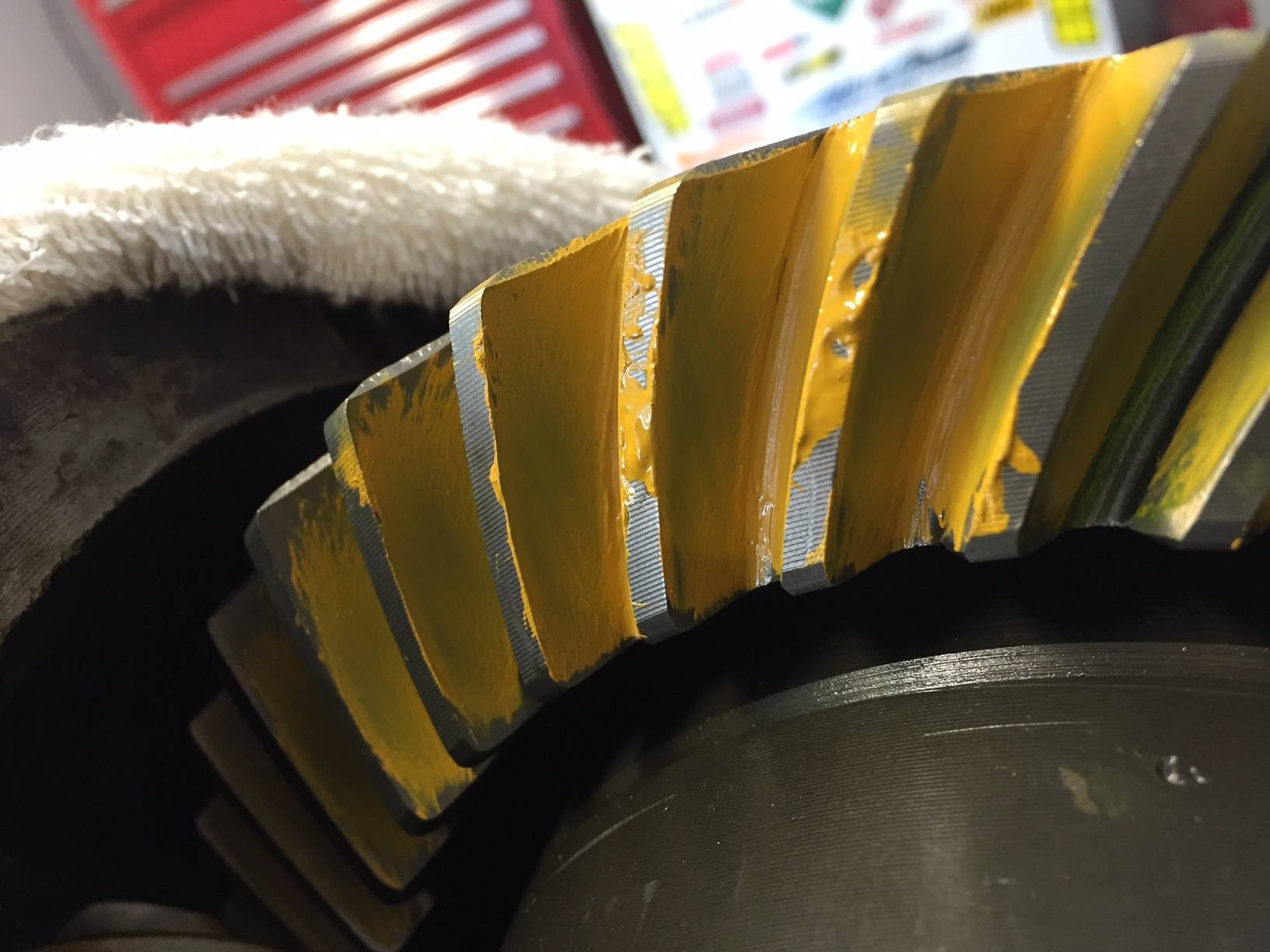

With my shim stack now at 084 and here is the pattern (not as good as 094 IMO). Notice the marks on the carrier were it hit at 094. I checked distance between the pinion head and carrier with the 084 stack and have about 015 in clearance. Hard to check but I was a using a feeler gauge then confirmed it with my calipers. It seems tight to me and honestly I would not have ever checked it had this not happened so I do not know what a safe distance is!

I pressed the old bearing off the 4.56 gear and checked dimensions on it, the setup up bearing, the new one I put on with heat/freeze and the 2nd new one I ordered to replace the first one I had to remove. No more than 001 difference. The new and set-up are all koyo HM803149N, the original is a Bower.

With my shim stack now at 084 and here is the pattern (not as good as 094 IMO). Notice the marks on the carrier were it hit at 094. I checked distance between the pinion head and carrier with the 084 stack and have about 015 in clearance. Hard to check but I was a using a feeler gauge then confirmed it with my calipers. It seems tight to me and honestly I would not have ever checked it had this not happened so I do not know what a safe distance is!

fishy68

Tyr Fryr's Inc.

Setup looks a little shallow now. BTW: next time don't go so crazy with the checking compound. You have so much slopped on it the pattern is somewhat hard to read

Setup looks a little shallow now. BTW: next time don't go so crazy with the checking compound. You have so much slopped on it the pattern is somewhat hard to read

Sorry bout that, My Lovely assistant got a little carried away with the marker paste.

By "Shallow" I assume you mean the pinion needs to have shim added. My concern is the clearance for the carrier, at 015 now it seems tight. Is my only choice to have the pinion shaved? A spool is out of the question..

Probably has to do with the 742 came with the Dana Clutch SG. It is somewhat smaller in diameter than the cone SG. But after building these for many years, I can't say I have ever run into the interference problem your having.

Probably has to do with the 742 came with the Dana Clutch SG. It is somewhat smaller in diameter than the cone SG. But after building these for many years, I can't say I have ever run into the interference problem your having.

It did have the DANA in it originally. I was having issues sometime around 1986 and swapped the carrier. Forgot I had done that and when I was restoring the car recently I was surprised when I saw it was the cone unit. It's all coming back to me now. I ran it that way for years with the 4.56 gears and never had an issue at temp. The 4.56 pinion head is much smaller though! Increased my shim to 090 and it looks close enough. The 4.56 pinion had an 090 on it. Now my carrier clearance is about 007. What to do???

Last edited:

Probably has to do with the 742 came with the Dana Clutch SG. It is somewhat smaller in diameter than the cone SG. But after building these for many years, I can't say I have ever run into the interference problem your having.

Thanks for the insight you win the "chicken dinner".

I remember when moving from GA to FL I had to put the original 489/3.23 back in. When I got to FL I could not find the rub spool cause the roll pin was always loose. Frustrated I put the 4.56 ring gear on the cone center from the 489. Bet if I choose a 3.73 or higher to put in now I would have never even had this issue! What are your thoughts on shaving the 3.55 pinion? It seems to contact or almost contact right on the edge where it is chamfered furthest from the ring gear. The power lock is long gone and a new one is $600 pricey!!! Not really interested in a used one that I have no way of trusting. The cone came out of my 28k car and maybe has 35k of use now so I trust it and it has always been tight!

fishy68

Tyr Fryr's Inc.

I'd have it shaved down. .007 is pretty darn close and you need to run the proper shim for the correct pinion depth or it'll most likely howl like a banshee

fishy68

Tyr Fryr's Inc.

Dr. Diff sells new powerlok's for about 350.

Like fishy68 said, that is pretty close. Cutting the face of the pinion certainly won't hurt a thing. Though I might consider turning the SG down a little. Softer metal and easier to cut.

RustyRatRod

Caput villa stultus

Probably has to do with the 742 came with the Dana Clutch SG. It is somewhat smaller in diameter than the cone SG. But after building these for many years, I can't say I have ever run into the interference problem your having.

That IS a cone style he has.

-

Similar threads

- Replies

- 11

- Views

- 925

- Replies

- 2

- Views

- 769

- Replies

- 4

- Views

- 750