Yes Rob, here is what I have found:

That info is not accurate if you do the calculations... Those are book numbers, and not actual...

I tried to do the compression calculations with those numbers and they don't work out... The only way to know for sure is to measure an actual set...

I have a set of 67 920 heads which are listed to be 57 cc in that book (I have a copy of it myself) but actually measure 63 cc's after my head guy went through them and may have done a clean up mill cut to square them back up... You can't trust the book numbers - they do not add up...

The X and J heads are listed at 65 cc and I've measured them at 70 - 72 cc...

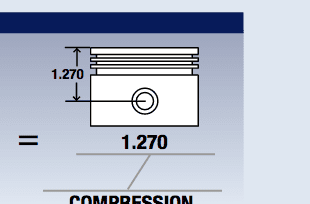

To calculate your true compression for your particular set of components, see my How-to Check Compression thread:

How to Check Compression

Chrysler likes to run to the fat side of their tolerances...

Example: The engine that I worked on had aluminum heads and cast iron block... If there was a complete engine with a defect that couldn't be shipped, it went to be torn down and the parts recycled... The heads would sometimes get scratches on the head gasket face and need to be re-milled to get the scratches off and the surface back to the smoothness spec... So we ran the first time heads just to the top (fat side) of the tolerance so we could do a mill cut or two to bring them back to usable condition... We would save them until we had a few pallets of them and batch them through the head line where the block face was re-milled... We would adjust the machine to run a light clean up cut on that face, then set it back up for the first time through heads afterwards... It saves us from having to scrap heads for light scratches in them...

We also ran the block head decks to the top of the tolerance for the same reason, but they weren't scratched as easily as the aluminum surfaces on the heads as they were cast iron...

That early edition of How to Rebuild a Small Block Mopar is a great book, I've had one and used it for years and learned alot from it especially when I first started out building engines... I like the early edition with the gold cover better than the revised edition as they removed the parts ID chapter in the later editions... A must have in my opinion for anybody starting out on SB LA engines...