Trick Flow quoted me "less than" $1900 per pair. I'm hoping that these will be all I ever need on my

470 low-deck stroker street motor that I have under construction. Compression ratio will be 10.09:1.

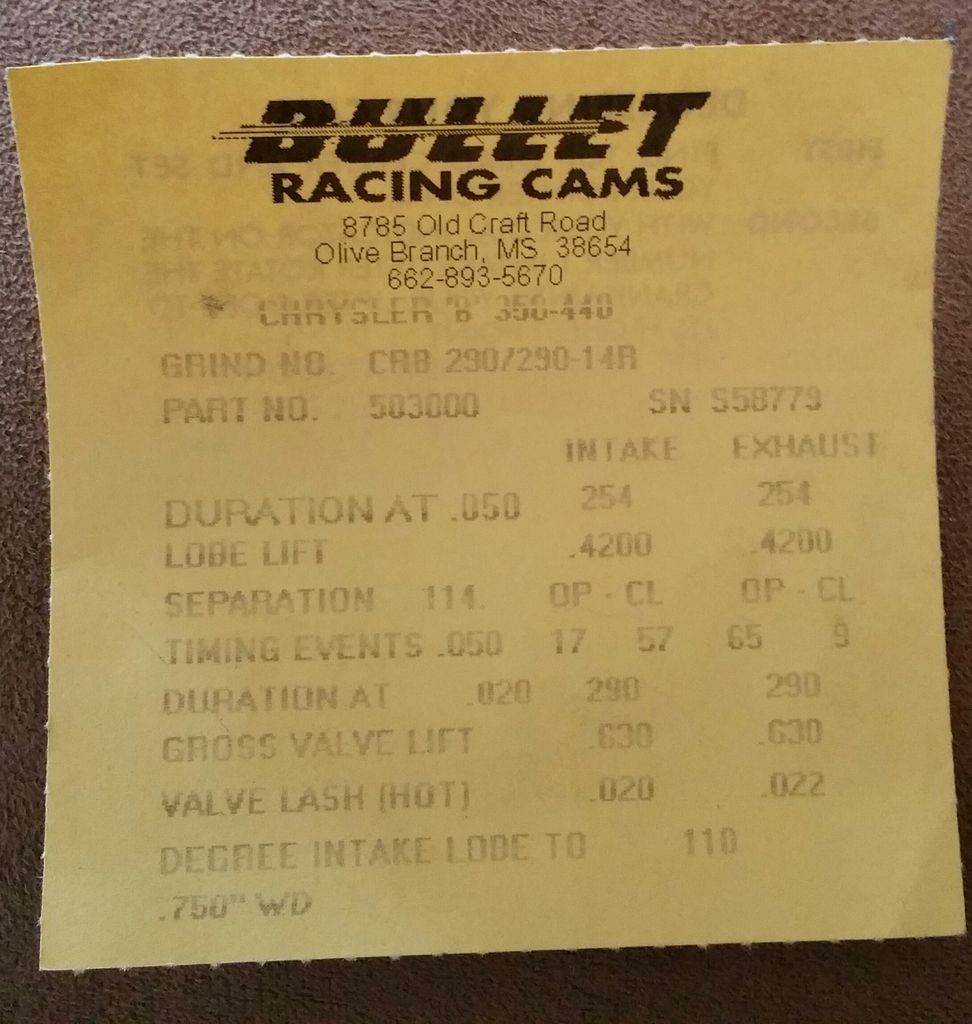

I'm considering either the largest Comp hydraulic roller (.544 int lift) or a small solid roller in the area

between .570 and .620 lift. Opinions on the camshaft selection will be much appreciated. I

probably won't be going to the race track.

Link: http://www.trickflow.com/pressreleases/powerport240cylinder/

I will never run another hydraulic roller cam without bushing the lifter bores. So, maybe this cam? Comp Cams XR292R solid roller, 254/260 @ .050, .620/.627 lift with 1.6 rockers.

In a 451 stroker, 9.5:1, ported 452 iron heads.......588 lb-ft and 621 HP

Oh yeah, I forgot. The 452 heads were flowing 290 cfm @ .700 lift. With the TrickFlow heads you should be able to run a smaller cam for the same results.