That’s a heavily machined to fit intake flange.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old Race 340 Teardown

- Thread starter Super Sleeper

- Start date

-

Ironracer

Gearhead

I didn't really read the whole article till just know. Yes. Makes sense. It was for a W-2, but who knows whT machine work was done? And what is angle head milling?That’s a heavily machined to fit intake flange.

Exactly! Heck of a mill though.

Ironracer

Gearhead

After a close look w/ my half blind eyes, the existing flange is GONE! (Well, not really, but Damn near it!)Exactly! Heck of a mill though.

pishta

I know I'm right....

I bet its milled >400 thou. Run a tape across the china wall where it intersects the head and the intake, both my 273 and 360 measure very close to 7.5 inches. If its milled this will be <7.5. did you mention rod length? Those BME rods can be custom made to any length as the big end has a lot of room to offset. Even the little end looks to be forged long and they drill it to final length.

Super Sleeper

Well-Known Member

Pishta, if I'm understanding correctly the dimension across the intake manifold valley, between the two head lands, I measured as 6.848". So considerable milling, consistent with the work done on the manifold? Seems like way too much.I bet its milled >400 thou. Run a tape across the china wall where it intersects the head and the intake, both my 273 and 360 measure very close to 7.5 inches. If its milled this will be <7.5. did you mention rod length? Those BME rods can be custom made to any length as the big end has a lot of room to offset. Even the little end looks to be forged long and they drill it to final length.

View attachment 1715804382

The rod length is a little harder to estimate with the piston still assembled. I used a straight edge to extend the rod mating surface parallel to the wrist pin and measured to my eyeballed center of the wrist pin and got a measure of ~6.075" The rod mating surface is serrated, so I assume the actual measuring surface would be at half the tooth depth. Unfortunately, the BME receipt I have doesn't have any part no. details.

I have the original receipts from Brooks Racing Components (BRC) which calls out the piston as 10-1-55-251. Google says that the current shop RaceTec (in Huntington Beach) is the second generation of BRC so I thought maybe they could decode the number and give me some piston dimensions. They're pretty close to you, do you know anybody there?

Last edited:

pishta

I know I'm right....

I pass by that part of town (aerospace side) frequently. Ill check if I can look them up.

That narrow dimension of 6.848 seeps to prove that block is decked lower forcing the heads closer and making the stock intake width unuseable, hence the mod to get the mounting plane closer, we cut and weld.

That narrow dimension of 6.848 seeps to prove that block is decked lower forcing the heads closer and making the stock intake width unuseable, hence the mod to get the mounting plane closer, we cut and weld.

Rat Bastid

Dunamis Metron

Pishta, if I'm understanding correctly the dimension across the intake manifold valley, between the two head lands, I measured as 6.848". So considerable milling, consistent with the work done on the manifold? Seems like way too much.

The rod length is a little harder to estimate with the piston still assembled. I used a straight edge to extend the rod mating surface parallel to the wrist pin and measured to my eyeballed center of the wrist pin and got a measure of ~6.075" The rod mating surface is serrated, so I assume the actual measuring surface would be at half the tooth depth. Unfortunately, the BME receipt I have doesn't have any part no. details.

I have the original receipts from Brooks Racing Components (BRC) which calls out the piston as 10-1-55-251. Google says that the current shop RaceTec (in Huntington Beach) is the second generation of BRC so I thought maybe they could decode the number and give me some piston dimensions. They're pretty close to you, do you know anybody there?

I love history. Especially automotive history. It would appear (historically anyway) that about the time that that engine was built aftermarket support for Chrysler connecting rods was pretty sorry. From my research about the only steel rods at that time were offered by DC and Carrillo. And the Carrillo’s were really expensive. One option was to use a 6 inch Chevrolet rod, and decking the block about .125 to make it all go together. As I posted earlier, the pistons are out of the deck about what I thought. When I looked at the piston in that engine I saw a pretty small compression height. That means that either the stroke is pretty long (it’s not long by today’s standard) or the rod is really long (6 inches is not a long rod) or the block has been decked to make it all work. If I had that engine, I would change the rods to steel, get the compression down to a pump gas number and change the cam. Then I would go out and beat the brakes off it like I stole it.

TT5.9mag

Two atmospheres are better than one

Wish I could hit the agree button multiple times.I love history. Especially automotive history. It would appear (historically anyway) that about the time that that engine was built aftermarket support for Chrysler connecting rods was pretty sorry. From my research about the only steel rods at that time were offered by DC and Carrillo. And the Carrillo’s were really expensive. One option was to use a 6 inch Chevrolet rod, and decking the block about .125 to make it all go together. As I posted earlier, the pistons are out of the deck about what I thought. When I looked at the piston in that engine I saw a pretty small compression height. That means that either the stroke is pretty long (it’s not long by today’s standard) or the rod is really long (6 inches is not a long rod) or the block has been decked to make it all work. If I had that engine, I would change the rods to steel, get the compression down to a pump gas number and change the cam. Then I would go out and beat the brakes off it like I stole it.

I love history. Especially automotive history. It would appear (historically anyway) that about the time that that engine was built aftermarket support for Chrysler connecting rods was pretty sorry. From my research about the only steel rods at that time were offered by DC and Carrillo. And the Carrillo’s were really expensive. One option was to use a 6 inch Chevrolet rod, and decking the block about .125 to make it all go together. As I posted earlier, the pistons are out of the deck about what I thought. When I looked at the piston in that engine I saw a pretty small compression height. That means that either the stroke is pretty long (it’s not long by today’s standard) or the rod is really long (6 inches is not a long rod) or the block has been decked to make it all work. If I had that engine, I would change the rods to steel, get the compression down to a pump gas number and change the cam. Then I would go out and beat the brakes off it like I stole it.

Man! I love your reply! Right behind ya.

My favorite part of your post which just about gets me standing up and fist pumping is the very end!

Absolutely 100%! All day long my man, all day long!Then I would go out and beat the brakes off it like I stole it.

To the OP. Enjoying this thread and look forward to this dissection to rebuilt completion.

When I first started racing this stuff was just coming out, the kit car engines were the new thing and were really looked up to in circle track racing. I have raced the 355 engines for many years. There were aluminum rods for drag guys and the standard heavy I beam for the circle guys. A set of these were for sale on here alittle while ago, these were all stock length, I guess maybe someone could of had something trick made. Mopar and Keith black were the cranks we ran. To go with a longer stroke it was either custom or offset ground. The w-2 heads were new and the Bible is what you had to digest it all with. A friend of mine seen the D.C. Book and crapped his pants that the factory had a 2" thick book about building engines, he was a chevy guy. This brings up a lot of good memories, life was good back then if you had a mopar.

Not sure when the x block came out, the big rage for us was a t/a block and putting aftermarket 4 bolt caps on them, they had a solid main web.

Dartswinger70

Well-Known Member

I bet it was hard to compete against an small block engine like that in the late 70s. Ford had Cleveland heads but what would a Chevy run ?

I dunno... I guess you could call Jenkins Competition and ask them...

Super Sleeper

Well-Known Member

...If I had that engine, I would change the rods to steel, get the compression down to a pump gas number and change the cam. Then I would go out and beat the brakes off it like I stole it.

Man. I think we are all on that wavelength, huh?

A56

Street Survivor

Yep, I believe we're all imagining that beast in our A body'sMan. I think we are all on that wavelength, huh?

What year is that publication from ?Here is a shot of a 1993 Mopar Performance catalogue showing the forged crankshafts available at the time. Yours should be the P4120312 or equivalent. The last 3 digits were often punched into the front counterweight face.

View attachment 1715804279

Thanks Chris

stixx

Well-Known Member

1993 he wrote...

I bought a 360 of similar vintage that was built by someone who ended up being quite big in Slant 6 racing apparently. it was obvious that they spent too much time reading about rod ratio, as it had 6.625" long BME aluminium rods in it. BME rods from the early 80's aren't as durable as what is available now, the set in this engine hadn't done a bunch of work, but the big ends on two had started to distort. The bolts should thread in and easily, if they are starting to bind up slightly, they are on their way out.

There was some cool stuff in the engine, but it was very much outdated. I ended up parting it out. The rods I sold individually, people buy them for man caves or steering column clamps for hot rods etc.

Best of luck with your project.

There was some cool stuff in the engine, but it was very much outdated. I ended up parting it out. The rods I sold individually, people buy them for man caves or steering column clamps for hot rods etc.

Best of luck with your project.

Joe Mc

No Car Like A MoPar!

Cool thread. Subscribed. My condolences on the loss of your brother. My thoughts on the engine, as a tribute to your brother, keep it exactly as it is/was put it in a body what you & he were thinking and go race it. Just my thoughts.

Krooser

Building Chinese Free Engines since 1959...

Randy is the guy at RaceTecPishta, if I'm understanding correctly the dimension across the intake manifold valley, between the two head lands, I measured as 6.848". So considerable milling, consistent with the work done on the manifold? Seems like way too much.

The rod length is a little harder to estimate with the piston still assembled. I used a straight edge to extend the rod mating surface parallel to the wrist pin and measured to my eyeballed center of the wrist pin and got a measure of ~6.075" The rod mating surface is serrated, so I assume the actual measuring surface would be at half the tooth depth. Unfortunately, the BME receipt I have doesn't have any part no. details.

I have the original receipts from Brooks Racing Components (BRC) which calls out the piston as 10-1-55-251. Google says that the current shop RaceTec (in Huntington Beach) is the second generation of BRC so I thought maybe they could decode the number and give me some piston dimensions. They're pretty close to you, do you know anybody there?

Krooser

Building Chinese Free Engines since 1959...

Angle milling removes more material from the head surface towards the intake...raises compression but also straightens the air path into the engine.I didn't really read the whole article till just know. Yes. Makes sense. It was for a W-2, but who knows whT machine work was done? And what is angle head milling?

Mopar small blocks have 18 degree heads. By angle milling you can lower that number a couple degrees. In my dirt world 9 to 13 degrees is the ticket.

Super Sleeper

Well-Known Member

Man, thanks for that! I have to find a way to make some accurate measurements. My gearhead friend is coming over today, I'm hoping to go over my options with him. The input from this thread helps immeasurably.Angle milling removes more material from the head surface towards the intake...raises compression but also straightens the air path into the engine.

Mopar small blocks have 18 degree heads. By angle milling you can lower that number a couple degrees. In my dirt world 9 to 13 degrees is the ticket.

Super Sleeper

Well-Known Member

Had a talk with my friend, more about his projects than mine, but it did help me make up my mind. I'm going drag racing. I can start with the Valiant with the street 360 and 4-speed I have in it right now and hopefully graduate to the 340 (355) once I have gone through it. Judging by the one rod bearing I have looked at there should be plenty of life in the rods for make enough runs to make me happy!

Funny thing, while he and his family were here this arrived:

So we both had a quick look. Really got the pulse rate up!

I also started reading this thread The Plymouth Weslake DOHC Motor from the 60's

Really good references. I was always a fig fan of the Gurney-Weslake projects, especially the Eagle F1 car. I think I will have to find a copy of the Mopar Performance Handbook by Larry Schreib.

I recognized a lot of you from that thread so please continue with the feedback.

Funny thing, while he and his family were here this arrived:

So we both had a quick look. Really got the pulse rate up!

I also started reading this thread The Plymouth Weslake DOHC Motor from the 60's

Really good references. I was always a fig fan of the Gurney-Weslake projects, especially the Eagle F1 car. I think I will have to find a copy of the Mopar Performance Handbook by Larry Schreib.

I recognized a lot of you from that thread so please continue with the feedback.

Nice book!

It’s a shame they don’t auto update LOL!

That is a excellent reference book of what they did yesteryear. Just swing in modern parts or equivalents for those worn out & you’ll be good to go.

It’s a shame they don’t auto update LOL!

That is a excellent reference book of what they did yesteryear. Just swing in modern parts or equivalents for those worn out & you’ll be good to go.

Super Sleeper

Well-Known Member

Thanks. I want to keep it as "old school" as I can. Will be looking for a set of W2 fenderwell headers for the 66 A-body. I have not yet found the pair that came off of it.

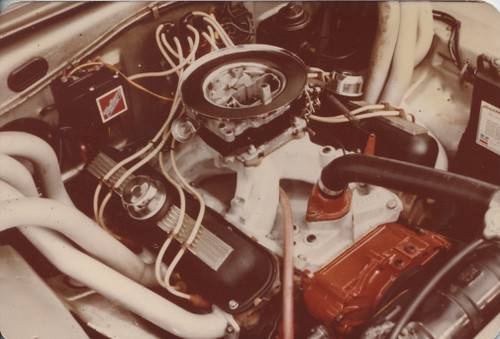

Last version without Paxton by Jim Harris, on Flickr

Last version without Paxton by Jim Harris, on Flickr

-

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 5

- Views

- 1K

- Replies

- 23

- Views

- 2K