loubee

Well-Known Member

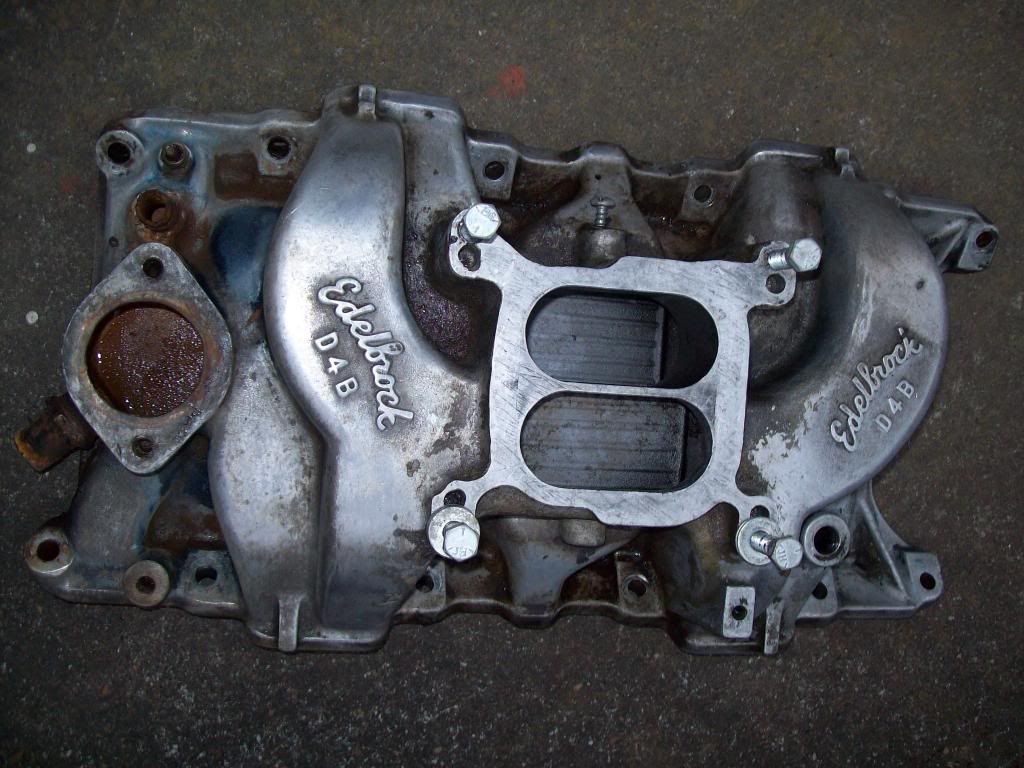

Does anyone make an aluminum 4 barrel manifold for a 64 with a 273. I currently have an Edelbrock Performer but it has managed to crack at a plug near the thermostat housing. However, I understand the Performers were for 66 and later models and have larger ports and slightly different mount hole angles. My second question is how complicated is it to drill/ream out the later manifold. Cause I don't believe this one can be welded. Any sage advice greatly appreciated.