I love this thread showing the play by play steps you are taking! Car is simply awesome and I love the fact that your daughter is right there with you as you rebuild this gem! I will reference a lot of this information as I slowly work through the steps on my 70 Duster.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

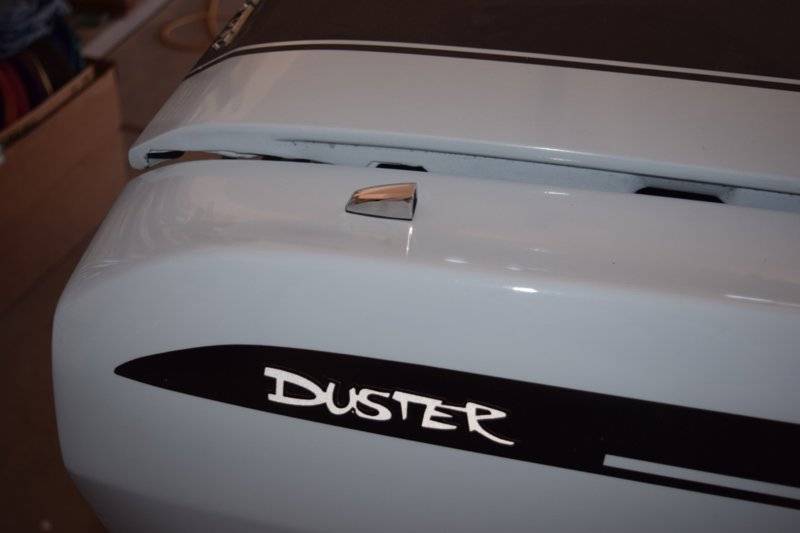

1972 Duster Build with my Daughter

- Thread starter Jim Kueneman

- Start date

-

I love this thread showing the play by play steps you are taking! Car is simply awesome and I love the fact that your daughter is right there with you as you rebuild this gem! I will reference a lot of this information as I slowly work through the steps on my 70 Duster.

With the Coronet thread on FBBO a few likened it to looking forward to grabbing a beer and "coming over to my garage every weekend". I do it for myself too. Now I have a record of what we did and when things needs changing/fixing its nice to have this as a reference.

Warning to all the haters out there. Very shortly the '64 Mustang fluted rocker moulding will be on the Duster and there will be no negative comments.... We held them up to the car tonight and they look awesome.

Princess Valiant

A.K.A. Rainy Day Auto

Ditto, as above mentioned.

This thread is getting me motivated to tear into my B1 72 demon. The two cars are so similar except for one being a Plymouth and the other a dodge version.

Thanks for this thread

This thread is getting me motivated to tear into my B1 72 demon. The two cars are so similar except for one being a Plymouth and the other a dodge version.

Thanks for this thread

Spring break! And Kaelyn has the flu.... I took the rest of the week off so it figures. I ended up working on the car anyway and she came out to sit in the seat and talk for 2 hours straight

Seat Tracks

Here are the cool sliders/rollers. This soft plastic that have ball bearing captured on the sides and a roller on the top... The bearings caused lots of galling on the track so make sure you file it smooth before painting.

Now slide the top track on and over slide it. Then you can put the second plastic bushing on and then slide the upper track back over it and your done.

Here you can see the dimples from the bearing on the track..

All done.

Restored the mirror and visors. Are these the right visors for this car?

Reworked the headliner in this area and made it much tighter. Looks a lot better. You can play a tune on it like a drum it is so tight.

Same on this side.

Glued the insulation under the package shelf and installed the seat back for good.

I mark the seat hole buy pushing an o-ring pick from the bottom.

Seat Tracks

Here are the cool sliders/rollers. This soft plastic that have ball bearing captured on the sides and a roller on the top... The bearings caused lots of galling on the track so make sure you file it smooth before painting.

Now slide the top track on and over slide it. Then you can put the second plastic bushing on and then slide the upper track back over it and your done.

Here you can see the dimples from the bearing on the track..

All done.

Restored the mirror and visors. Are these the right visors for this car?

Reworked the headliner in this area and made it much tighter. Looks a lot better. You can play a tune on it like a drum it is so tight.

Same on this side.

Glued the insulation under the package shelf and installed the seat back for good.

I mark the seat hole buy pushing an o-ring pick from the bottom.

Carpet knife around the pick and your done.

Install the cross wire to release the tracks on both sides of the seats.

All installed ready for the seat (need to take them off to do that)

Cleaned up the brackets and painted them with SEM satin black.

Seat back latch spring. I NEED ANOTHER, ANYONE HAVE ONE OF THESE?

All done. Anyone have knobs for this? Need both sides.

Seats assembled and trim restored with the bead blaster and Herb's Bright Blue spray dye.

It IS blue.

Install the cross wire to release the tracks on both sides of the seats.

All installed ready for the seat (need to take them off to do that)

Cleaned up the brackets and painted them with SEM satin black.

Seat back latch spring. I NEED ANOTHER, ANYONE HAVE ONE OF THESE?

All done. Anyone have knobs for this? Need both sides.

Seats assembled and trim restored with the bead blaster and Herb's Bright Blue spray dye.

It IS blue.

Kaelyn was feeling better so she came out. All she did was sit in the seat and talk for 2 hours

She did help me slide in the dash so we could see where to mount the Bluetooth stereo out of the way.. Then she sat in the car again....

New AMD bumper gets the license bracket and light.

Then we mounted it.

She did help me slide in the dash so we could see where to mount the Bluetooth stereo out of the way.. Then she sat in the car again....

New AMD bumper gets the license bracket and light.

Then we mounted it.

View attachment 1715306383

Restored the mirror and visors. Are these the right visors for this car?

Bummer about the Flu, you need the longer ones that have the rubber tip that goes into the mirror.

Restored the mirror and visors. Are these the right visors for this car?

Bummer about the Flu, you need the longer ones that have the rubber tip that goes into the mirror.

View attachment 1715306383

Restored the mirror and visors. Are these the right visors for this car?

Bummer about the Flu, you need the longer ones that have the rubber tip that goes into the mirror.

Thought they were wrong. They are trashed anyway so that will be a future upgrade to the correct ones

Only got a half day in today after taking the girls to town for Breakfast.

Sprayed undercoating in the front wheel wells. Only put it where the wheel directly throws stones...

We then got the seal kit out and got the inner fender shield ready to install by installing the seals. Also installed the flap on the starter shield that was in the kit.

We also had GREAT luck with the decals. The trick is fresh decals I think. The others where ordered then it got cold and they sat around for a few months. Also cutting the rear trim in half (top/bottom) then pealing just the center and getting that set before working towards the ends helped a lot... It came out 100% better than last time. And we bought hardware to mount the license plate. Kaelyn is stoked ;)

Next we installed the front and back glass trim clips.

We started to pull the steering column apart and got stuck. Need to do a youtube search.. Dinner time anyway.

Tomorrow take the dash back out and finish up the electrical and install the dash for real.

Sprayed undercoating in the front wheel wells. Only put it where the wheel directly throws stones...

We then got the seal kit out and got the inner fender shield ready to install by installing the seals. Also installed the flap on the starter shield that was in the kit.

We also had GREAT luck with the decals. The trick is fresh decals I think. The others where ordered then it got cold and they sat around for a few months. Also cutting the rear trim in half (top/bottom) then pealing just the center and getting that set before working towards the ends helped a lot... It came out 100% better than last time. And we bought hardware to mount the license plate. Kaelyn is stoked ;)

Next we installed the front and back glass trim clips.

We started to pull the steering column apart and got stuck. Need to do a youtube search.. Dinner time anyway.

Tomorrow take the dash back out and finish up the electrical and install the dash for real.

Last edited:

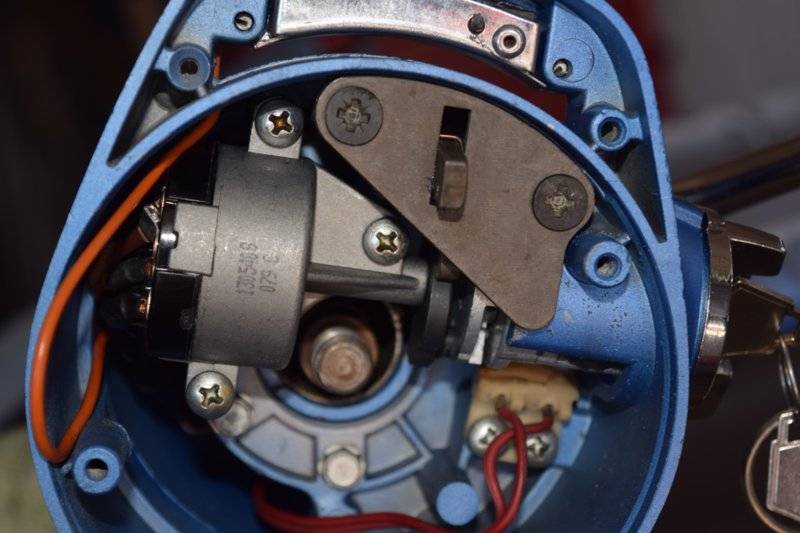

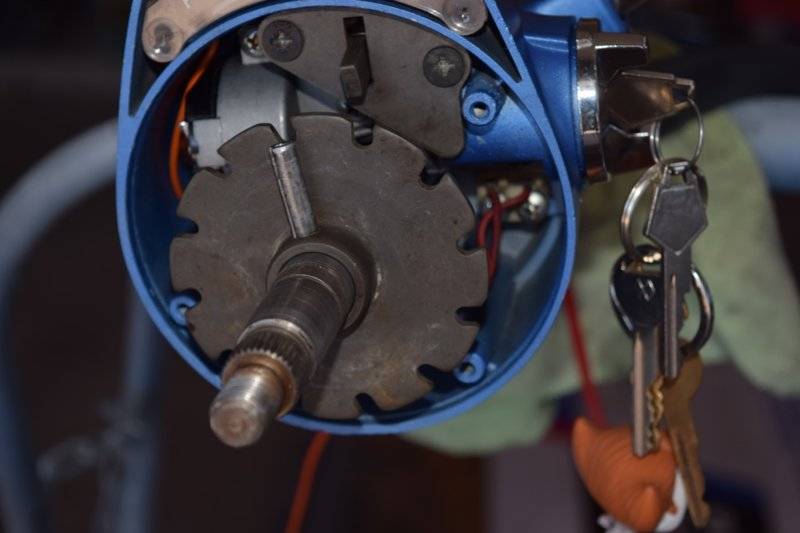

Wasn't sure what to work on today so since we started to pull the steering column apart last night we decided if we could get it apart and cleaned up ready to paint by noon we could get the dash out and wiring finished in the afternoon

.... Sort of worked out.... Once we got the column apart and realized I had all the parts we needed to restore it (I took a guess a few months ago) I got energized and fired up the paint.....

The snap rings go in front and behind the bearing in the first casting.. We will take better photos of reassembly... Disassembly sometimes get a bit disorganized as I try to figure out how things come apart...

Firewall plate orientation and gasket.

Here is why you replace all things electrical in 50 year old cars!

The lock cam is confusing so here are a lot of photos of it and the spring.. Note that it will pull out as one unit and you never have to take it apart. Just clean it and re-grease it.

With the key out press the pin in the hole and pull the lock out.

Another shot of how the wheel lock pins slide out as a unit.

.... Sort of worked out.... Once we got the column apart and realized I had all the parts we needed to restore it (I took a guess a few months ago) I got energized and fired up the paint.....

The snap rings go in front and behind the bearing in the first casting.. We will take better photos of reassembly... Disassembly sometimes get a bit disorganized as I try to figure out how things come apart...

Firewall plate orientation and gasket.

Here is why you replace all things electrical in 50 year old cars!

The lock cam is confusing so here are a lot of photos of it and the spring.. Note that it will pull out as one unit and you never have to take it apart. Just clean it and re-grease it.

With the key out press the pin in the hole and pull the lock out.

Another shot of how the wheel lock pins slide out as a unit.

Last edited:

Some close ups of the wheel lock spring and cams.

Now press the pin and pull the lock!

Kaelyn cleaned up all the parts with Acetone while I bead blasted and prepared for paint. The upper bearing just needed to be cleaned and repacked with grease. Just like new and likely 100% better quality then any replacement.

Shot everything with reduced SPI Epoxy primers. Only wanted enough for the grip on the metal, nothing more.

We went to get lunch while the epoxy dried and then to the PO to pick up the next batch of parts. The new sill plates came in. Kaelyn installed these all by herself while I prepared for the B5 paint.

Also yesterday we installed the new OER fender blinkers...

Now press the pin and pull the lock!

Kaelyn cleaned up all the parts with Acetone while I bead blasted and prepared for paint. The upper bearing just needed to be cleaned and repacked with grease. Just like new and likely 100% better quality then any replacement.

Shot everything with reduced SPI Epoxy primers. Only wanted enough for the grip on the metal, nothing more.

We went to get lunch while the epoxy dried and then to the PO to pick up the next batch of parts. The new sill plates came in. Kaelyn installed these all by herself while I prepared for the B5 paint.

Also yesterday we installed the new OER fender blinkers...

Last edited:

The firewall plates got a coat of black then a mix of SPI Universal Clear with a 33% flat and a bit of reducer to help make the column a bit flatter than the dash. I think it hit it perfect. If we wanted to make the dash more original then this is the mix.

It was too late to work on the dash so we installed the inner fender shields. Again aftermarket (AMD) and they needed a bit of grinding on the lower bolts holes and the drivers needed a bit off the edge so it was not pushing the fender outwards... Other than that they look great. Also installed the headlight gaskets in the inner fender. Kaelyn did them all on her own. She is getting very good with tools. She did a lot of work today on her own! Proud of her!

It is always fun to see what little goodies SPI ships with orders from repeat customers ;)

We mocked up the new switches and I realized I ordered the wrong switch. Luckily O'Reilly's in Tucson has one is stock so need to get there tomorrow.

It was too late to work on the dash so we installed the inner fender shields. Again aftermarket (AMD) and they needed a bit of grinding on the lower bolts holes and the drivers needed a bit off the edge so it was not pushing the fender outwards... Other than that they look great. Also installed the headlight gaskets in the inner fender. Kaelyn did them all on her own. She is getting very good with tools. She did a lot of work today on her own! Proud of her!

It is always fun to see what little goodies SPI ships with orders from repeat customers ;)

We mocked up the new switches and I realized I ordered the wrong switch. Luckily O'Reilly's in Tucson has one is stock so need to get there tomorrow.

Ditto, as above mentioned.

This thread is getting me motivated to tear into my B1 72 demon. The two cars are so similar except for one being a Plymouth and the other a dodge version.

Thanks for this thread

Was wondering where you went @Rainy Day Auto! Thought I ticked you off or something

And just so you don't think I am smarter than I look here is a great series by a master. This is E Body but once you get past the telescoping part the columns are the same....

Princess Valiant

A.K.A. Rainy Day Auto

not a chance, I am still around and watching. Taking notes for when I get started on my demon.Was wondering where you went @Rainy Day Auto! Thought I ticked you off or something

Just let you know when you re-attach the turn signal lever, put a dab of blue loctite on the screw threads. Don't ask how I found out.

Just let you know when you re-attach the turn signal lever, put a dab of blue loctite on the screw threads. Don't ask how I found out.

I got to take my steering wheel off the Coronet twice a few weeks after I finished it too.... I understand..

383Scampman

Well-Known Member

This is IMO one of the best documented restoration builds I have ever see . the fact that you are including a family member just adds icing to the cake . Please , please keep up the photo posts until drive date and beyond . OUTSTANDING work and thanks for sharing . Later, Tom

Column time!

The lower bushing is only to keep the shift tube from being loose. Various places claim this needed for steering.. Not true. So I masked off where the bushing use to be..... seemed like a good idea but it failed.... more to follow....

You can buy a split bushing so you can install it without disassembling the entire column so that started an idea. Why not just split the original and shim it out with electrical tape. If I need to replace it with a split type in the future it is doable but this saved me $30 and is likely better.

There we go... so I think.....

The shift casting goes on next..

Guess what...the original did not have the clip to hold the bushing so it worked it way up into the tube so my tape is in the WRONG place... damn...

There is a depression in the tube so tighten the allen just a bit then slide the casting around until it loosens up and the allen falls in the depression. Then snug it down.

Bend the edges of the tube to keep it from turning if the allen comes loose.

Lube up the cam for the shifter lever to ride on. This is the casting for the key cylinder.

Install the 4 bolts an torque them down.

The lower bushing is only to keep the shift tube from being loose. Various places claim this needed for steering.. Not true. So I masked off where the bushing use to be..... seemed like a good idea but it failed.... more to follow....

You can buy a split bushing so you can install it without disassembling the entire column so that started an idea. Why not just split the original and shim it out with electrical tape. If I need to replace it with a split type in the future it is doable but this saved me $30 and is likely better.

There we go... so I think.....

The shift casting goes on next..

Guess what...the original did not have the clip to hold the bushing so it worked it way up into the tube so my tape is in the WRONG place... damn...

There is a depression in the tube so tighten the allen just a bit then slide the casting around until it loosens up and the allen falls in the depression. Then snug it down.

Bend the edges of the tube to keep it from turning if the allen comes loose.

Lube up the cam for the shifter lever to ride on. This is the casting for the key cylinder.

Install the 4 bolts an torque them down.

Last edited:

Notice all the scratches in the shift indicator... Looked horrible.

Wet sand the deep scratches out with 800

Now use 1500 wet to get the 800 scratches out. If I had 3000 I would have used it but I did not have any.

Now VERY VERY carefully buff it with a soft wheel. If you get it to hot you will melt the plastic and you will be staring over....

Masked off to paint the black

SEM satin black

Just like newish....

Cleaned and installed the indicator light housing from the rear.

Wet sand the deep scratches out with 800

Now use 1500 wet to get the 800 scratches out. If I had 3000 I would have used it but I did not have any.

Now VERY VERY carefully buff it with a soft wheel. If you get it to hot you will melt the plastic and you will be staring over....

Masked off to paint the black

SEM satin black

Just like newish....

Cleaned and installed the indicator light housing from the rear.

Son of a $itch.... Don't for get the damn spring washer.... Took it back apart and greased and installed the spring washer...

Bead blasted the wheel/horn pad/wire cover and scrubbed with Acetone. Took it outside and sprayed with Herb's dye. Have I mentioned this stuff is amazing?

Now is the time to put the firewall plates on. Added tape so it won't scratch the paint when handling it.

Lubed and installed the steering wheel lock. Don't forget to latch the spring to the notch just above on the right...

Buffed out the shift lever and installed it. Don't forget the spring.

Here is the new cylinder and the button you push to remove it.

Cylinder installed just push in the pin and shove it home.

Installed the steering lock cover plate then washed the Coronet and took it to Sierra Vista to pick up the new Standard Ignition switch..

Switch installed.

Wheel lock plate slide on, just drive the roll pin home.

Bead blasted the wheel/horn pad/wire cover and scrubbed with Acetone. Took it outside and sprayed with Herb's dye. Have I mentioned this stuff is amazing?

Now is the time to put the firewall plates on. Added tape so it won't scratch the paint when handling it.

Lubed and installed the steering wheel lock. Don't forget to latch the spring to the notch just above on the right...

Buffed out the shift lever and installed it. Don't forget the spring.

Here is the new cylinder and the button you push to remove it.

Cylinder installed just push in the pin and shove it home.

Installed the steering lock cover plate then washed the Coronet and took it to Sierra Vista to pick up the new Standard Ignition switch..

Switch installed.

Wheel lock plate slide on, just drive the roll pin home.

Now install the 2/3 clip for behind the upper bearing

slide on the cover to keep the roll pin from every coming out.

The final casting goes on next.

The indicator was dipped in my Coronet Orange earlier in the day so it was installed and aligned.

Now the upper bearing goes in. the original was in perfect condition after cleaning it with Acetone and repacking.

After tapping it in install the snap ring and use to seat it the rest of the way. I use a socket to drive it home.

When the bearing is all the way in the snap ring ends will come together as it falls in the groove.

Install the hazard light

Work the new turn signal harness down the column.

slide on the cover to keep the roll pin from every coming out.

The final casting goes on next.

The indicator was dipped in my Coronet Orange earlier in the day so it was installed and aligned.

Now the upper bearing goes in. the original was in perfect condition after cleaning it with Acetone and repacking.

After tapping it in install the snap ring and use to seat it the rest of the way. I use a socket to drive it home.

When the bearing is all the way in the snap ring ends will come together as it falls in the groove.

Install the hazard light

Work the new turn signal harness down the column.

Install the plate and screws.

Buffed out the turn signal arm and lined it up with my o-ring pick... Use lock tight on this screw or you will be sorry..

Wheel goes on next. Thought I was cool marking it but this wheel and shaft are indexed with a flat spot so it only goes on one way...

Horn mechanism bead blasted and cleaned.

Horn pad blasted and clear coated.

Like new'ish...

Horn wire connected.

Horn pad snapped on.

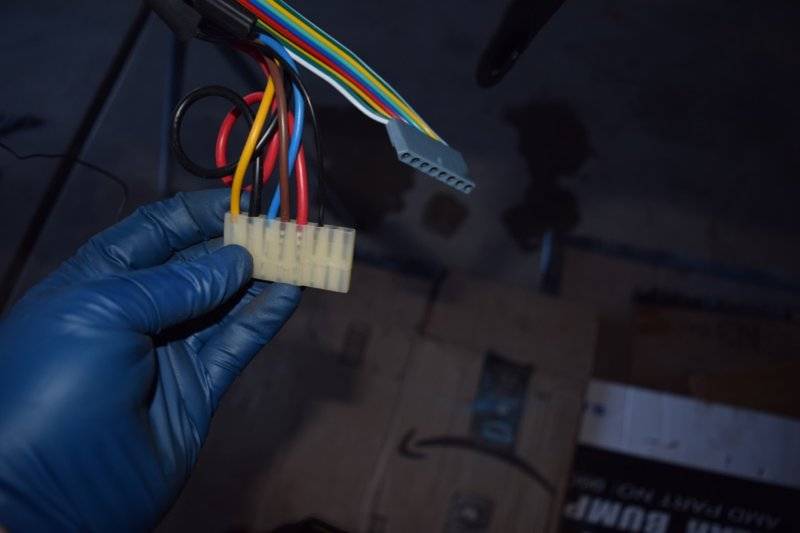

Someone at a desk thought a big heat shrink tube around the ignition switch wires was a good idea. Not in practice. Cut it back so it would fit in the harness cover.

Switches are universal so for a '72 the main power feeds just go to the main connector. Snapped them in.

Buffed out the turn signal arm and lined it up with my o-ring pick... Use lock tight on this screw or you will be sorry..

Wheel goes on next. Thought I was cool marking it but this wheel and shaft are indexed with a flat spot so it only goes on one way...

Horn mechanism bead blasted and cleaned.

Horn pad blasted and clear coated.

Like new'ish...

Horn wire connected.

Horn pad snapped on.

Someone at a desk thought a big heat shrink tube around the ignition switch wires was a good idea. Not in practice. Cut it back so it would fit in the harness cover.

Switches are universal so for a '72 the main power feeds just go to the main connector. Snapped them in.

Last edited:

Some stuff to sort out. The new switch has a black wire where the original had the light for the shifter.... Not sure what to do about that yet...

Cleaned and installed the plastic cover with zip ties.

What can you do... you have to mock it up after all that work don't you?

Cleaned and installed the plastic cover with zip ties.

What can you do... you have to mock it up after all that work don't you?

Last edited:

-