Agree. Maybe he's talking about turns in on the idle stop screw (aka idle speed screw, throttle position screw, ...)Sounds like he's talking about idle mixture screws. 3 1/2 might be a bit rich but it shouldn't produce ported vacuum unless it's idling too fast.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pulling V.A at idle

- Thread starter Ironracer

- Start date

-

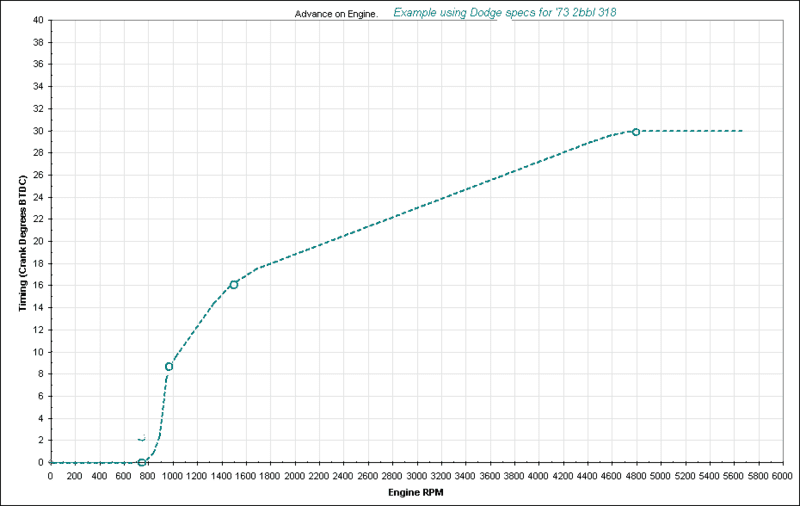

Timing at RPM

Example 1

Using a factory '73 318 distributor, timing at 1000 rpm is 9* BTDC, initial is zero.

Example 2

Setting a factory '69 318 distributor so the engine had 18* BTDC at 1000 rpm, the initial is 11* BTDC. But we can't measure that until the engine is slowed to 700 rpm or less.

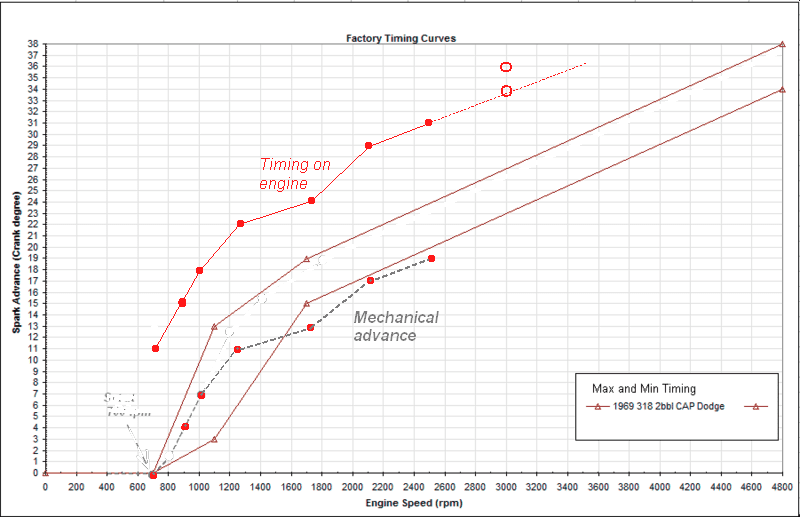

Some examples of factory small block high performance timing curves in this post.

1968 340 timing

But bottom line is get the idle sorted out, then deal with any adjustments to the timing curve that may be needed.

Example 1

Using a factory '73 318 distributor, timing at 1000 rpm is 9* BTDC, initial is zero.

Example 2

Setting a factory '69 318 distributor so the engine had 18* BTDC at 1000 rpm, the initial is 11* BTDC. But we can't measure that until the engine is slowed to 700 rpm or less.

Some examples of factory small block high performance timing curves in this post.

1968 340 timing

But bottom line is get the idle sorted out, then deal with any adjustments to the timing curve that may be needed.

Last edited:

I hate giving specific setup advice but in this case is close enough to mine so I will.

I'd try the timing where I said above.

Crack the secondary throttles either a 1/4 or a 1/2 turn further open.

Then adjust the idle mix screws. Start with them 1 1/2 turns out. Turn in and if the engine rpm drops turn out. 1/8 turns at time. When its warmed up, try turning in again. As soon as it looses rpm, or misses, turn back out 1/4 or 3/8s. If timing has changed, reset timing. Readjust mix. Now test in gear.

Try again at different primary throttle openings (within the range of .020 to .040" on trnasfer slots. Refer to your notes so as not to exceeed this.) If it strongest with at .040 or more, then try opening the secondary throttles another 1/4 or 1/2. Repeat above as needed.

If going over 1 turn on the secondary throttles I'd consider drilling the primary throttles.

You'll then need to reduce the idle air bleeds. Stick some wire in each one. You can search for posts where I've shown that as I've got to hit the road.

I'd try the timing where I said above.

Crack the secondary throttles either a 1/4 or a 1/2 turn further open.

Then adjust the idle mix screws. Start with them 1 1/2 turns out. Turn in and if the engine rpm drops turn out. 1/8 turns at time. When its warmed up, try turning in again. As soon as it looses rpm, or misses, turn back out 1/4 or 3/8s. If timing has changed, reset timing. Readjust mix. Now test in gear.

Try again at different primary throttle openings (within the range of .020 to .040" on trnasfer slots. Refer to your notes so as not to exceeed this.) If it strongest with at .040 or more, then try opening the secondary throttles another 1/4 or 1/2. Repeat above as needed.

If going over 1 turn on the secondary throttles I'd consider drilling the primary throttles.

You'll then need to reduce the idle air bleeds. Stick some wire in each one. You can search for posts where I've shown that as I've got to hit the road.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,914

- Reaction score

- 12,265

If your VA is plumbed to the proper spark-port, then my guess would be'

wrong /defective gasket on the metering block, or pouched parts, on account of; the primary throttles would have to be way far open to activate the VA; like 1600/1800 rpm far. Which with 18* of idle-timing, and 9inches of vacuum, does not compute, for me.

Maybe this is linked to the fat mixture; as in ruptured PV diaphragm or wrong PV gasket..

In any case, I would take the M-block off for inspection.

If perchance your secondary side has a PV, then you better check it too.

wrong /defective gasket on the metering block, or pouched parts, on account of; the primary throttles would have to be way far open to activate the VA; like 1600/1800 rpm far. Which with 18* of idle-timing, and 9inches of vacuum, does not compute, for me.

Maybe this is linked to the fat mixture; as in ruptured PV diaphragm or wrong PV gasket..

In any case, I would take the M-block off for inspection.

If perchance your secondary side has a PV, then you better check it too.

Ironracer

Gearhead

Its the older. 484, 284 MP cam.RPM idle? How nasty is your cam?

Ironracer

Gearhead

No Sir, the Lil flat head ones behind the float bowls. Primary sides only... fuel/ air mixture? Standard starting point is 1.5 turns out bottom, usually... ? At least that's what Grandpa told meAgree. Maybe he's talking about turns in on the idle stop screw (aka idle speed screw, throttle position screw, ...)

Ironracer

Gearhead

It's a 12 year old carb, I bought new, supposedly has PV blow out protectionIf your VA is plumbed to the proper spark-port, then my guess would be'

wrong /defective gasket on the metering block, or pouched parts, on account of; the primary throttles would have to be way far open to activate the VA; like 1600/1800 rpm far. Which with 18* of idle-timing, and 9inches of vacuum, does not compute, for me.

Maybe this is linked to the fat mixture; as in ruptured PV diaphragm or wrong PV gasket..

In any case, I would take the M-block off for inspection.

If perchance your secondary side has a PV, then you better check it too.

Ironracer

Gearhead

I haven't messed w/ the secondary blade adj... it's outta the box, 12 years oldI hate giving specific setup advice but in this case is close enough to mine so I will.

I'd try the timing where I said above.

Crack the secondary throttles either a 1/4 or a 1/2 turn further open.

Then adjust the idle mix screws. Start with them 1 1/2 turns out. Turn in and if the engine rpm drops turn out. 1/8 turns at time. When its warmed up, try turning in again. As soon as it looses rpm, or misses, turn back out 1/4 or 3/8s. If timing has changed, reset timing. Readjust mix. Now test in gear.

Try again at different primary throttle openings (within the range of .020 to .040" on trnasfer slots. Refer to your notes so as not to exceeed this.) If it strongest with at .040 or more, then try opening the secondary throttles another 1/4 or 1/2. Repeat above as needed.

If going over 1 turn on the secondary throttles I'd consider drilling the primary throttles.

You'll then need to reduce the idle air bleeds. Stick some wire in each one. You can search for posts where I've shown that as I've got to hit the road.

Ironracer

Gearhead

The main idle speed? No Sir, but I did set the acc pump clearanceAgree. Maybe he's talking about turns in on the idle stop screw (aka idle speed screw, throttle position screw, ...)

The 484/284 or possibly 274 cam is pretty mild . It shouldnt require any mods to the carb . I have run several over the years.

Clarification... when I say mods I mean drilling the secondaries etc..

JMO 12* initial with a 484 cam is not the best spot. That's factory 340 cam timing specs and they were light.

I'd put 18-20 on it and see how things work at idle.

Drilling a carb is always the last resort for me. Timing usually helps clean things up if inadequate.

I'd put 18-20 on it and see how things work at idle.

Drilling a carb is always the last resort for me. Timing usually helps clean things up if inadequate.

I think he said it was on 18 most recently. That's why I asked if he has ever verified TDC with a piston stop. Something's making him get into the transfer slots I believe. Retarded timing could sure be it.JMO 12* initial with a 484 cam is not the best spot. That's factory 340 cam timing specs and they were light.

I'd put 18-20 on it and see how things work at idle.

Drilling a carb is always the last resort for me. Timing usually helps clean things up if inadequate.

Ironracer

Gearhead

That's an old vid w/ the same engine, running points. The 340 is now electronic, in a Duster, pulled drivetrain, outta the 66 Sat, after my deceased wife wrecked it and bent the frame. Sorry for the muddy clarification! My Bad....JMO 12* initial with a 484 cam is not the best spot. That's factory 340 cam timing specs and they were light.

I'd put 18-20 on it and see how things work at idle.

Drilling a carb is always the last resort for me. Timing usually helps clean things up if inadequate.

Ironracer

Gearhead

Yessir, you are Correct, I'm at 18° ( maybe 19°) currently. Thank You Rusty! Dude, The Truck You Built is Sick, Vixen is coming Along Nicely too! Glad You and Kittle are rollin Her! Love it!!!!!I think he said it was on 18 most recently. That's why I asked if he has ever verified TDC with a piston stop. Something's making him get into the transfer slots I believe. Retarded timing could sure be it.

Ironracer

Gearhead

So, I guess I have another question.. is it an Issue to Run that Way? Or can I get Detonation? Or am I screwing myself out of initial timing, therefore HP?

That one is often confusing becuase of the way it has been written.The main idle speed? No Sir, but I did set the acc pump clearance

The pump should move immediately as the throttle rotates off of slow idle.

The 'clearance' is when the throttle is full wide open there should be travel remaining before the spring bottoms out . In other words with the throttle wide open, a feeler gage can be forced in between the lever and the adjuster.

18* at what rpm? This is the key.

yes it may end up being too much at 2400 rpm to use vac advance, or way too much at high rpm and wide open throttle. Its under heavy load, like wide open throttle 2 and 3 rd gear that too much timing advance can be really destructive. But unless you need to go racing, work on idle and then off idle. You can even drive it around the block at light and moderate throttle.

Last edited:

With a Holley 4150/60 set the initial throttle position as shown in the post above here:

Large RPM and Vacuum drop when shifting from park to gear

Tuning for performance procedure outlined here Setup for 750DP on this 408

Yup. We're on the same page. What caught Mike's attention was the 3.5 turns out. That's an awful lot.No Sir, the Lil flat head ones behind the float bowls. Primary sides only... fuel/ air mixture? Standard starting point is 1.5 turns out bottom, usually... ? At least that's what Grandpa told me

If you caught it above my suggestion was the same as your Grandpa's. Then when warmed up, adjust by turning in (leaner) until it looses rpm. Then turn it richer. Much easier to detect performance drop going from rich to lean. The reason to turn it richer once that point is established is because the test was in neutral and with load the engine will need a richer mix.

Great! So now if/when you crack them open you can keep track of how to return to factory. That's by taking notes on how many turns or fractions of the stop screw.I haven't messed w/ the secondary blade adj... it's outta the box, 12 years old

Same concept with the primary throttles. With the carb on the bench, measure the transfer slop length visible below the throttle plates when the idle stop screw is just touching. Then note how many turns it takes to open the throttles so .020 .030 and .040" of the slots are revealed. This way you will know how much the transfer slots are exposed by counting the turns on the idle speed screw. Saves a lot of time removing and reinstalling the carb after each adjusment.

I drew an illustration of how that effects the idle mix, along with a photo of measuring with drill bits in this post. Some other posts there about too rich issues too.

MOPAROFFICIAL

Oogliboogli

Well, I'm using a Matco dial back, I figuredit was a good light, traded a chainsaw fer it, got it from a mechanic pal o mine...Not 100% sure that my damper is "dead on" TDC.... been driving that mill for 12 years, some years daily.. Hmmm Rob, don't know if Ya remember, but remember the Detonation scare? Could the thing have spun, showing Less ?

Haven't read all the replies yet but if this is a scenario where you have a little bit of camshaft and you only have 2 Corner idle as in primary, then there's a good chance you have the throttle blades open too far and the ported vacuum is now active.Hi Everyone, Hope All Y'all, Your Family's, Friends, and any one else are all Well! I have a quick (I hope) question.

Had a Distributor done. Finally had a Bro come by to watch the tach and run the mat pedal. Before he stopped in, I checked the idle airs... 3.5 turns out ( a buddy "helped" do that when i went to the store)

So, when I set the timing ( Vac Advance disconnected, plugged hose) it was close to where it was supposed to be...

BUT, plugs were ugly, pig rich, ( pulled em and posted em here, different post)

Anyway, when I hooked up the VA, the idle snapped back to "life"! Sounded Way Tight, like it should! Question is : Why am I pulling Vac advance off Ported Vac?

Thanks Everyone!

If that were the case...you can lower the primary blades at the idle speed screw..then flip the carb over and you see a little flat head screw that adjusts the secondary throttle blades...open them just a hair more to compensate for the lowered primary idle speed... again if that's the case and there not some internal leak that's pushing fuel.

All assuming the timing is set right.

Ironracer

Gearhead

18-19° @ 900,in park...driving her ain't been an issue, even w/ the heavier car. Street driven in Tampa, Daily, for 2 years, but it's been a while for the Daily thing. Had the same Blue tag ( antique) for 12 years...That one is often confusing becuase of the way it has been written.

The pump should move immediately as the throttle rotates off of slow idle.

The 'clearance' is when the throttle is full wide open there should be travel remaining before the spring bottoms out . In other words with the throttle wide open, a feeler gage can be forced in between the lever and the adjuster.

18* at what rpm? This is the key.

yes it may end up being too much at 2400 rpm to use vac advance, or way too much at high rpm and wide open throttle. Its under heavy load, like wide open throttle 2 and 3 rd gear that too much timing advance can be really destructive. But unless you need to go racing, work on idle and then off idle. You can even drive it around the block at light and moderate throttle.

Ironracer

Gearhead

The only time I've tried to Tune er, was when I first started Streeting as a Daily Driver.. found an Article on FBBO, using a vacuum gauge, about 2500 Rpm, then bringing the screws in till highest idle, + best vacuumHaven't read all the replies yet but if this is a scenario where you have a little bit of camshaft and you only have 2 Corner idle as in primary, then there's a good chance you have the throttle blades open too far and the ported vacuum is now active.

If that were the case...you can lower the primary blades at the idle speed screw..then flip the carb over and you see a little flat head screw that adjusts the secondary throttle blades...open them just a hair more to compensate for the lowered primary idle speed... again if that's the case and there not some internal leak that's pushing fuel.

All assuming the timing is set right.

So odds are that its already advancing. When the engine slows down (transmission placed in gear) timing decreases. How much depends on how quick the primary advance is. it can be pretty dramatic as illustrated above. If you have four hands and an extra foot you can see that in the timing light and tach. Just be careful if measuring timing in gear! The extra hands and a foot on the brake is better than relying on chocks alone.18-19° @ 900,

Ironracer

Gearhead

I have a Talented gal that can watch a tach, while running the pedal.when I did the Vac GA thing, I used the idle screw and the tach, along w/ the vacc ga, solo I've had a Few of these Beasts break out on me at a high idle. SCARY MAN!!! Especially a 4 Dr D-200 w/ a Dana and 4:10s!!!!!!! Brutal Man!So odds are that its already advancing. When the engine slows down (transmission placed in gear) timing decreases. How much depends on how quick the primary advance is. it can be pretty dramatic as illustrated above. If you have four hands and an extra foot you can see that in the timing light and tach. Just be careful if measuring timing in gear! The extra hands and a foot on the brake is better than relying on chocks alone.

Pay close attention to post 44. I bet that will fix it.

Yote

Well-Known Member

Something I haven’t seen mentioned here but does vacuum can on distributor have adjustment in inlet

(Allen screw in tube) . It is my understanding that it can be adjusted to set when vacuum advance comes into play. Possibly a new can not adjusted or one messed with.

This may have been mentioned before and I missed it.

Don’t take this information as gospel as many on this forum know way MORE than I do . Just a thought.

Yote

(Allen screw in tube) . It is my understanding that it can be adjusted to set when vacuum advance comes into play. Possibly a new can not adjusted or one messed with.

This may have been mentioned before and I missed it.

Don’t take this information as gospel as many on this forum know way MORE than I do . Just a thought.

Yote

-