BigBlockMopar

BigBlockMember

Here are some pics and info about the 360ci engine I recently put together and put on my test-stand for camshaft break-in and checking for leaks or other issues.

The engine will a replacement for the stockish 318ci in my daily driven propane-powered '73 Dodge Dart.

The 318 has a wimpy 8.6:1 compression ratio. Not bad for put-putting around and while I managed to get some decent power out of it with a MegaSquirt ECU controlling timing, it's still no tyre-frier.

Goal with the freshly build 360 is to increase torque, efficiency and hopefully as a result, fuel-economy as well, as the current setup only gets me 10-12mpg.

The 360 had been run shortly before I bought it, but a scored bearing & crank issue made it seize up for the previous owner.

I rebuilt the engine with new bearings, new cam and located a freshly located .010" crankshaft.

Engine specs:

– 360ci +0.030″ overbore.

– Stock rotating assembly except for .030″ KB zero-deck pistons. Fully balanced.

– Iron heads, ‘302’ casting (closed chamber). milled to get 60-61cc chambers.

– Valves have been backcut and polished.

– Smoothed/polished Edelbrock Performer intake, w/ blocked heatriser ports.

- Gasketmatching.

– Tight piston-to-head quench-clearance of 0.025-0.030″.

– Intended rpm-range: 600-3000rpm. Max. rpm around 5000-6000 rpm.

– Fuel is Propane/LPG (±104 octane).

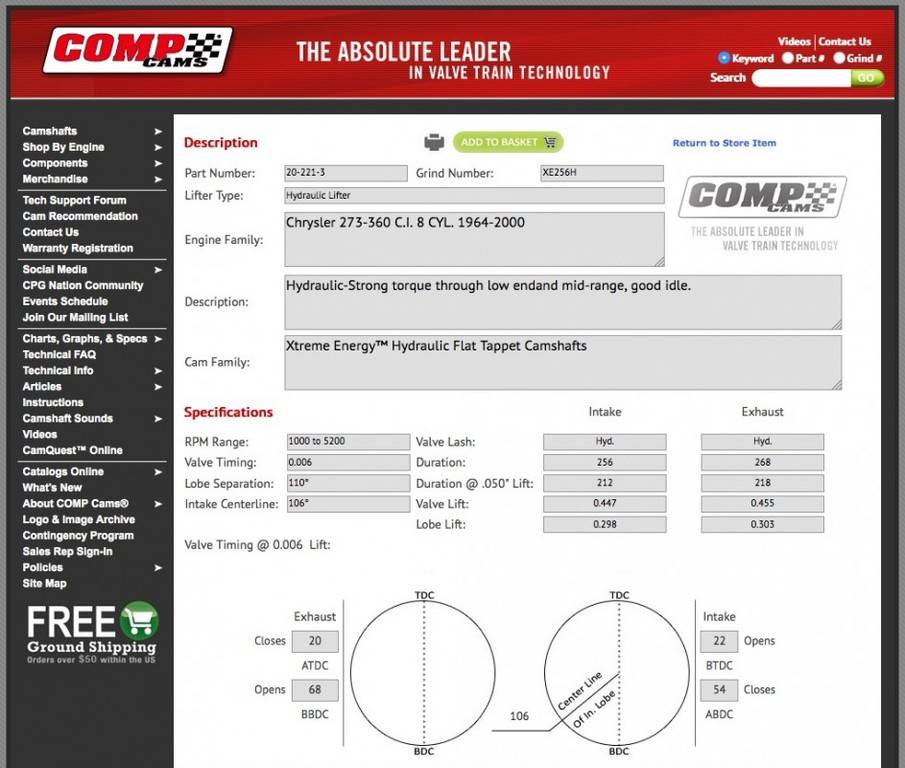

– CompCams Extreme Energy XE256H, used with 1.6 ratio rockers.

During the build I found the KB-piston ring gaps where too tight, so I corrected them to 0.025".

Did a number of other mods on the engine like;

- backcutting and polishing the valves,

- enlarging oil passages in the block,

- modify truck oilpickup to center-pan pickup,

- welded oilcontrol baffle in oilpan,

- modified/installed windage tray from other 360 engine.

- improved oil-transition channel between rear main-cap and oilpump.

- milled heads to 60cc head chamber.

The Mopar '302' heads are the Mopar '302'-casting swirl-port heads.

I gasketmatched and smoothed the runners and polished the chambers, along with some minor contouring of the swirl area.

The camshaft is a CompCams XE256H.

256° In / 268° Ex Adv. dur.

212° In / 218° Ex dur. @ .050"

With 1.6 rockers this will give resp. .4768/.4848" lift.

Lob.sep 110 - ICL 106

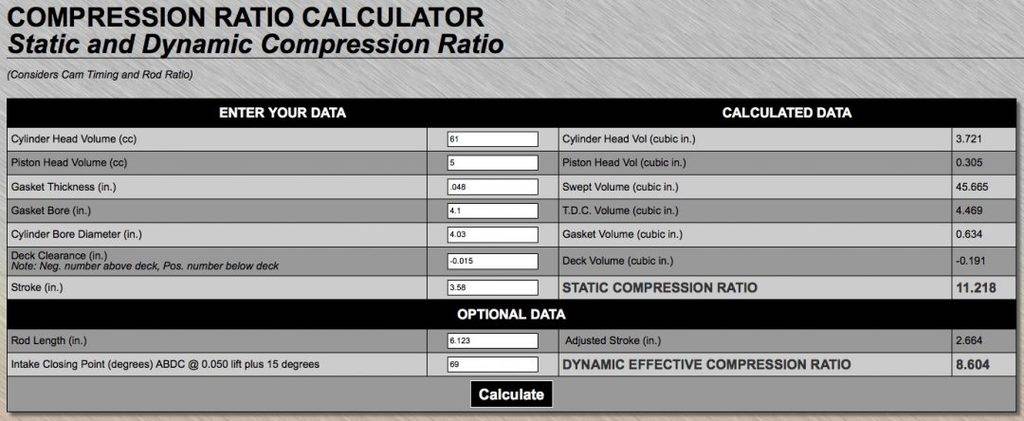

With the 11.3cr, this will give a DCR of 8.6:1.

Cam-card;

KB-DCR calculator;

To break-in the new cam I decided to built an engine-stand as well. Something I wanted to do a long time ago already, but it finally happened.

At the day of the engine's first start-up, I bought 5 gallon of 102 octane pumpgas to prevent any form of detonation.

In the car the engine will run on propane only.

The engine break-in went fairly smoothly, aside from the engine getting hot, and (probably because) one lifter failing to pump up.

So I had to stop and go ahead with the break-in after a short cool down period.

After running the engine with a different carb and distributor with quicker timing curve the engine ran pretty cool.

The engine will a replacement for the stockish 318ci in my daily driven propane-powered '73 Dodge Dart.

The 318 has a wimpy 8.6:1 compression ratio. Not bad for put-putting around and while I managed to get some decent power out of it with a MegaSquirt ECU controlling timing, it's still no tyre-frier.

Goal with the freshly build 360 is to increase torque, efficiency and hopefully as a result, fuel-economy as well, as the current setup only gets me 10-12mpg.

The 360 had been run shortly before I bought it, but a scored bearing & crank issue made it seize up for the previous owner.

I rebuilt the engine with new bearings, new cam and located a freshly located .010" crankshaft.

Engine specs:

– 360ci +0.030″ overbore.

– Stock rotating assembly except for .030″ KB zero-deck pistons. Fully balanced.

– Iron heads, ‘302’ casting (closed chamber). milled to get 60-61cc chambers.

– Valves have been backcut and polished.

– Smoothed/polished Edelbrock Performer intake, w/ blocked heatriser ports.

- Gasketmatching.

– Tight piston-to-head quench-clearance of 0.025-0.030″.

– Intended rpm-range: 600-3000rpm. Max. rpm around 5000-6000 rpm.

– Fuel is Propane/LPG (±104 octane).

– CompCams Extreme Energy XE256H, used with 1.6 ratio rockers.

During the build I found the KB-piston ring gaps where too tight, so I corrected them to 0.025".

Did a number of other mods on the engine like;

- backcutting and polishing the valves,

- enlarging oil passages in the block,

- modify truck oilpickup to center-pan pickup,

- welded oilcontrol baffle in oilpan,

- modified/installed windage tray from other 360 engine.

- improved oil-transition channel between rear main-cap and oilpump.

- milled heads to 60cc head chamber.

The Mopar '302' heads are the Mopar '302'-casting swirl-port heads.

I gasketmatched and smoothed the runners and polished the chambers, along with some minor contouring of the swirl area.

The camshaft is a CompCams XE256H.

256° In / 268° Ex Adv. dur.

212° In / 218° Ex dur. @ .050"

With 1.6 rockers this will give resp. .4768/.4848" lift.

Lob.sep 110 - ICL 106

With the 11.3cr, this will give a DCR of 8.6:1.

Cam-card;

KB-DCR calculator;

To break-in the new cam I decided to built an engine-stand as well. Something I wanted to do a long time ago already, but it finally happened.

At the day of the engine's first start-up, I bought 5 gallon of 102 octane pumpgas to prevent any form of detonation.

In the car the engine will run on propane only.

The engine break-in went fairly smoothly, aside from the engine getting hot, and (probably because) one lifter failing to pump up.

So I had to stop and go ahead with the break-in after a short cool down period.

After running the engine with a different carb and distributor with quicker timing curve the engine ran pretty cool.

Last edited: