Hemiorangeswinger

Dodge Material

Hemiorangeswinger, hats off to you. Good work and I look forward to watching the Youtube segments as well. I think it is great that you are using your skills to save that H code car. There were something like 13000 of them made in 1970. it sounds like a lot but I think ( just guessing) that half of them are left and out of that half, probably half need restored. I look forward to following your build as I am also putting mine back together. I didn't have as much metal work as you though. But my car is basically at the same stage, in epoxy primer ready for prep and paint. Keep up the good work, there are many of us cheering you on!!

Thanks for the compliment! I'm glad you're enjoying the thread/vids. Yeah I don't think too many 1970 340 Darts are around anymore.. I'm lucky if I see one or two at the car shows around here. I was looking for a Hemi Orange 340 Dart for years before I came across this one and I'm glad I was patient because this one has all the options I wanted, which probably helps a lot with the motivation on restoring it since it's needed so much to bring back from the dead!

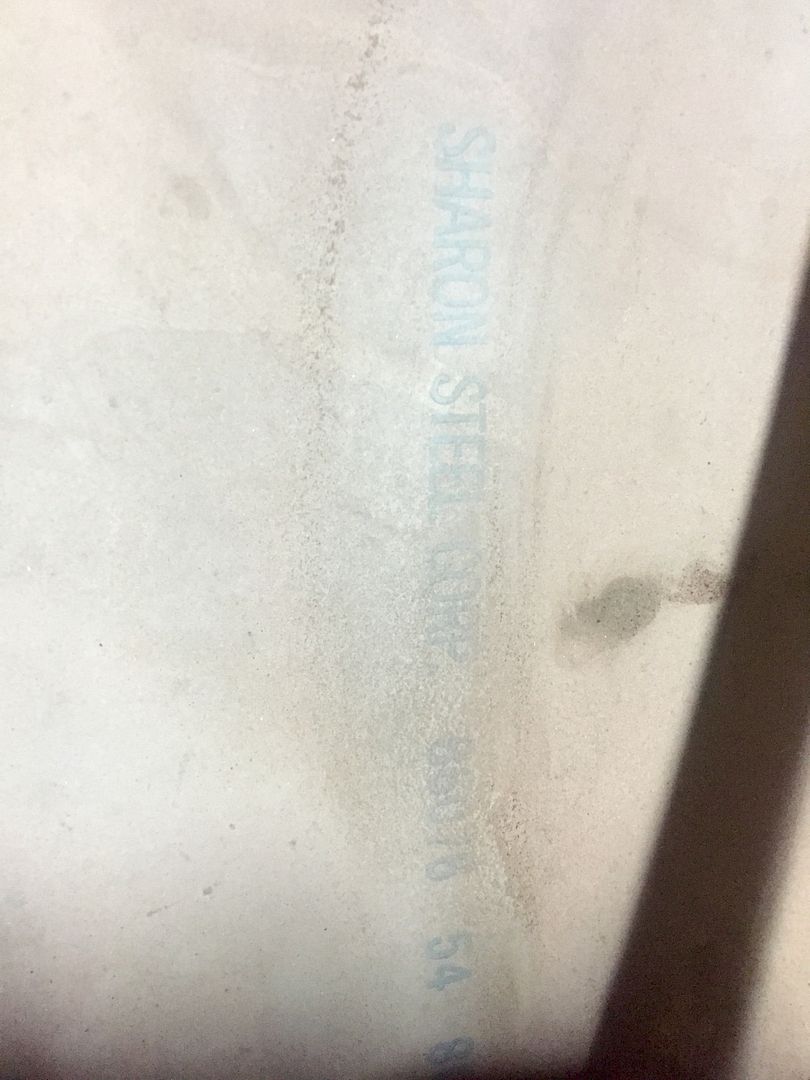

Mine is an early production car (sept 69) and I find it interesting that the early production ones never had the go wing provisions underneith the trunk lid. You have any pics of yours?

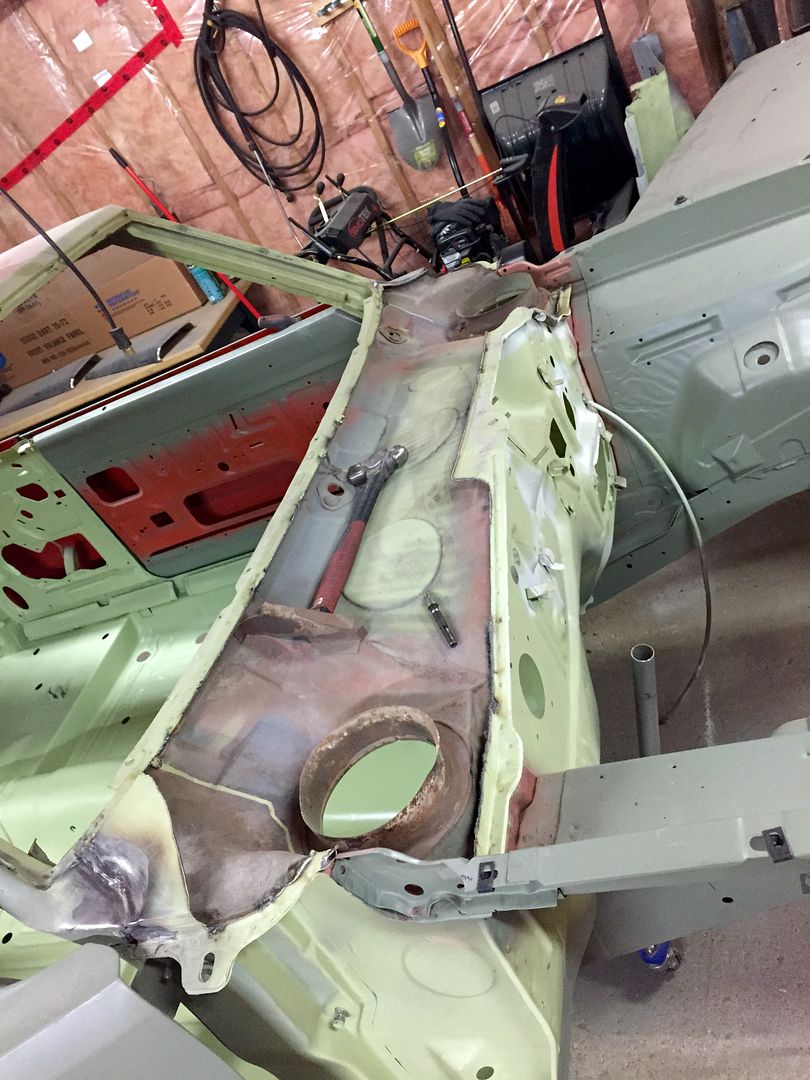

I started on removing the upper cowl assembly from my doner piece. I'm drilling the firewall/cowl seam from the bottom to retain all the original spot welds on the upper cowl so it looks factory under the hood when I panel bond (fuser structural) this lip to my car.. I will then weld the upper cowl on along the windshield seam and sides to retain the strength. When I remove the upper cowl from my car I will only drill the spot welds out thru the first layer of steel across the firewall seam so the original spotwelds will still be in place for the lower cowl/firewall.. It is a lot of work but should make for a seamless repair.