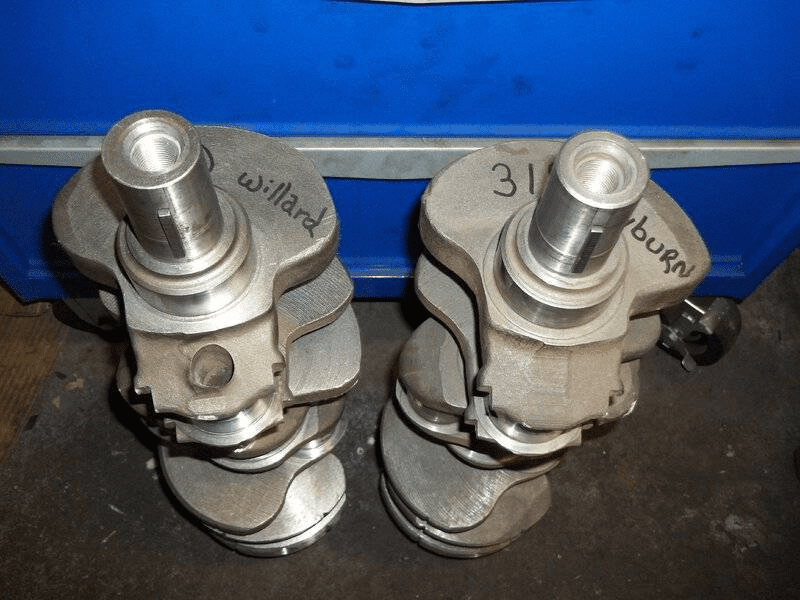

Forged crank 340 counter weights are not bigger than forged crank 318"s. they are the same casting #, BUT, rod journal 1 / 2 and journal 7/8 have a lightning hole bored into them to reduce the weight. Pics 340 left 318 right.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

273 dilemma

- Thread starter fireguyfire

- Start date

-

I thought that was just a /6 thingThe only issue you will have is the pocket in the convertor flange for the nose of the convertor. In approximately 1968 they enlarged the diameter of the recess in the crank to accommodate a larger nose on the convertor. If you can find a '67 and earlier crank, it's a drop-in; if you find a '68 or later crank, it will require a spacer bushing to be pressed into the crank to let it match up to the '67 and earlier convertor.

Not a snow balls chance in hell that they are the same other than the same stroke. Kima 318 or a 340 crank are the same, casting numbers are same. both are steel cranks

YUP. To offset the heavier connecting rods of the 340.Forged crank 340 counter weights are not bigger than forged crank 318"s. they are the same casting #, BUT, rod journal 1 / 2 and journal 7/8 have a lightning hole bored into them to reduce the weight. Pics 340 left 318 right.

View attachment 1716196562

Hot Rod magazine built a cast crank 340 using the 318-3 cast crank years back, so the cast cranks can be interchanged. The reasoning was that the 318-3 crank was primarily a truck crank and was supposedly stronger.

Wrong info in this thread.

Last edited:

I have with the 273 commando engine that is matching numbers in my 67 formula S

Sorry to be that guy but....but am having zero luck as I would love to save the matching numbers engine

There is nothing on the engine that ties it to the car except the engine build date being days to weeks before the car assy date.

Any 273 with a build date in the range will be undetectable as not being the OE engine. You will know but that is it

My 67 dart has the OE engine and was rebuilt once. But if it can't be bored again any engine built in the last quarter of 66 will work

Period correctSorry to be that guy but....

There is nothing on the engine that ties it to the car except the engine build date being days to weeks before the car assy date.

Any 273 with a build date in the range will be undetectable as not being the OE engine. You will know but that is it

My 67 dart has the OE engine and was rebuilt once. But if it can't be bored again any engine built in the last quarter of 66 will work

I have a ‘67 Cúda equipped with a 904 & have found that it has the older 18 spline count (IIRC it’s 18 spline) impossible to find a (performance) torque converter for. At the time, a company down the block from me open up and rebuilt and re stalled the OE converter that is now 650hp capable. It wasn’t a extremely pricey thing, expensive yea, but the car is up and running with the OEM converter in the OEM transmission and cheaper than getting a rebuilt newer style trans and converter by far!

Go here -> ProTorque | High Performance Drag Racing Torque Converters

Go here -> ProTorque | High Performance Drag Racing Torque Converters

jeff alder

Well-Known Member

64mopar64 has an entire 67 273 commando engine that i believe is partially tore down. give him a shout and see if he will sell you the crankshaft...goodluck and best regards

cudamark

Well-Known Member

As long as you're not going for a mega horsepower build, you can use just about any 273/318 crank. Regardless of which one you get, I would rebalance. The '64-7 273 crank would be the same as what you have....forged and with the small converter register. A 318 can be found in either forged or cast, both are internally balanced just like the 273 crank, so, rebalancing should be minimal. If you want a forged crank for added strength, look at a '62-7 318 crank. Those were all forged. '68 and later 318 forged cranks are mostly found in trucks and vans (and some industrial engines) mostly with a manual transmission. If your horsepower is below 400 HP, the cast 318 crank will work just fine. As mention, get the converter register bushing for a stock early 273/904 converter button. I used to have crank thrust surfaces welded back up, but, finding a machine shop that will actually do that work these days is getting hard to find, and the higher labor rate is something to consider too. I just had the same problem with my build, but, was lucky enough to have a spare crank. I kept the original crank in case I find a machine shop that will repair it for a reasonable cost.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,636

- Reaction score

- 13,871

the early 273s had very lightweight bushed rods and I think those ended up being used until ~69/70 in the 318LAs. By 73 the 318 was using the 340/360 rods but press-fit pins

Those later rods look nothing like the early rods.

I have available, a low-mileage 65 273 crank for the early rods, that I got in an engine back in the early 70s but it will need to go to the machine shop cuz the last time I saw it, it was a lil rusty.

Some say a guy can drive to Calgary from my place in a day, but I know for a fact that I can't ride it on a Motorcycle at any legal speedlimit and not fall asleep trying lol.

Google says ~13 hours.

Those later rods look nothing like the early rods.

I have available, a low-mileage 65 273 crank for the early rods, that I got in an engine back in the early 70s but it will need to go to the machine shop cuz the last time I saw it, it was a lil rusty.

Some say a guy can drive to Calgary from my place in a day, but I know for a fact that I can't ride it on a Motorcycle at any legal speedlimit and not fall asleep trying lol.

Google says ~13 hours.

I just can't imagine pulling a motor apart, changing the crank and not rebalancing the engine, or for that matter having the whole thing refreshed while it's out. If it's decent miles you might have a fresh motor for the cost of bearings, rings and a hone. If nothing else the bearings are a lot better quality than in 1967.

James Clews

Well-Known Member

Correct me if I am wrong but as far as I knew a 318-3 was a heavy duty truck motor and had a steel crank in it and fully floating rods as well as other strength parts.Hot Rod magazine built a cast crank 340 using the 318-3 cast crank years back, so the cast cranks can be interchanged. The reasoning was that the 318-3 crank was primarily a truck crank and was supposedly stronger.

RustyRatRod

Caput villa stultus

Nothing is ever "exactly" the same regarding balance from one engine to another. It will be best to get the reciprocating assembly balanced when replacing the crankshaft. Something a quality engine build should have done anyway.So a guy could use a 318 crank and the 273 rods and domed pistons and it would be exactly the same?

RustyRatRod

Caput villa stultus

This ^^^^^^ X 10,000.I just can't imagine pulling a motor apart, changing the crank and not rebalancing the engine, or for that matter having the whole thing refreshed while it's out. If it's decent miles you might have a fresh motor for the cost of bearings, rings and a hone. If nothing else the bearings are a lot better quality than in 1967.

but i saw this u-toob vidya where this guy said you can just mix n match all that stuff! it don matter tall!Nothing is ever "exactly" the same regarding balance from one engine to another. It will be best to get the reciprocating assembly balanced when replacing the crankshaft. Something a quality engine build should have done anyway.

I believe that 318-3 motors had forged cranks as did the first few years of LA 318s (red blocks).

64mopar64

Well-Known Member

Thanks Jeff, I think he knows but he also knows what it will cost to get it shipped half way across North America. Is there any way to know if the crank is forged or not without tearing the engine apart?64mopar64 has an entire 67 273 commando engine that i believe is partially tore down. give him a shout and see if he will sell you the crankshaft...goodluck and best regards

cudamark

Well-Known Member

It's just a matter of removing the oil pan. If the crank has the small converter register, it's a forged 273 crank.Thanks Jeff, I think he knows but he also knows what it will cost to get it shipped half way across North America. Is there any way to know if the crank is forged or not without tearing the engine apart?

Cudamark, this is a quote from one of your old posts from back in 2012 about 273 cranks. @64mopar64 read along.It's just a matter of removing the oil pan. If the crank has the small converter register, it's a forged 273 crank.

"The '64-7 273's have forged cranks.....the '68-9 273's used cast cranks. They will all swap into a 318 (or 340 for that matter) block but remember that the early 273 crank has a small register for the small snout converter those years so if you're running an automatic, you need to have a converter built or conversion parts to change to the later converter. A 318 could have either forged or cast cranks. I usually find the forged ones in trucks and manual transmission vehicles but that's not 100%. If they ran out of one or the other on the assembly line, any engine could have any crank. You should rebalance any time you swap a crank."

Inertia

Well-Known Member

Correct me if I am wrong but as far as I knew a 318-3 was a heavy duty truck motor and had a steel crank in it and fully floating rods as well as other strength parts.

I believe that 318-3 motors had forged cranks as did the first few years of LA 318s (red blocks).

The motor in my son's car in the Avatar, has a stage 3 truck crank in a 340, - should be balanced, but isn't, we threw it together with Frankenstein parts to run one weekend. Still in there several years and races later. 13.19 iirc, it ran so well we left it alone. No drama.

We're building a stroker for it .

No noticeable shake or vibration, flame on .

Pic #26 shows the difference between the standard and 340 cranks, with the hole thru the front and back throw

I am in no way suggesting not balancing is acceptable.

I often experiment with my own chit !

Last edited:

Dave_J

Well-Known Member

Its been said many times before. But if you are reusing the 273's pistons, wrist pins and rods then any Poly 318, or forged 318/340 crank will fit but still should be balanced.

It is true that in 1962-63 when they were doing the engineering of the 273 they used the Poly 318 crankshaft and connecting rods as they had them all tooled up and on the shelf.

But the mass of a Poly 318 piston bob weight is a lot more that the smaller bore 273 so they tooled up some very thick walled wrist pins to match the Poly's bob weight

But if you want the best, replace the 273's HEAVY wrist pins with some light full floating pins, do the David Vizard's crank weight reduction trick and rebalance it. They will be able to remove over 6 pounds of rotating mass

It is true that in 1962-63 when they were doing the engineering of the 273 they used the Poly 318 crankshaft and connecting rods as they had them all tooled up and on the shelf.

But the mass of a Poly 318 piston bob weight is a lot more that the smaller bore 273 so they tooled up some very thick walled wrist pins to match the Poly's bob weight

But if you want the best, replace the 273's HEAVY wrist pins with some light full floating pins, do the David Vizard's crank weight reduction trick and rebalance it. They will be able to remove over 6 pounds of rotating mass

be careful, many 318 polys had an 8 bolt crank - not hard to resolve, just use a Hemi flex plate...

-

Similar threads

- Replies

- 14

- Views

- 542