Just to make sure I'm reading this correctly you used a 383 crankshaft, turned into that stroke, lol I thought u used a 383 block and got a .125 overbore . Lol I really misread that, good work rob !Yes I've heard of it. In fact I have one i'm building for my bodyshop buddy's '72 RoadRunner. I turned a 383 forging to 3.545" stroke x 4.375" bore= 426.33 ci. I'm using a 6.7" Rod with a Mahle piston with a 1.32" CHT. < Correction it is a 1.480" CHT-I've got a lot of builds going on--LOL.I've got a nice solid lifter Hughes grind going in it. The plan is to build HP up to and beyond 7000 rpm for some roadracing style fun. The bottom end photos show how the short stroke and long rod doesn't pull the piston skirt out of the bore at BDC. Judging how easy this thing is to turn over I think this should make some power AND last a long time. J.Rob

View attachment 1716115724

View attachment 1716115725

View attachment 1716115726

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

400/426 Stroker. Ever heard of one?

- Thread starter slimjim

- Start date

-

400 block and turned 383 crankJust to make sure I'm reading this correctly you used a 383 block @ 4.375 in bore ? Did you sleeve it ? Or is it a 400 block?

Reason I'm asking is because that's a .125 overbore and if you got that bore from a 383 I can see a resurgence in 383 popularity.

Also if you did sleeve a 383 could you pm me the sleeve p/n you used.

Be much appreciated!!!

Thanks

You caught it before I edited my post. Thanks400 block and turned 383 crank

On a quick overview of the 340 to your offset low deck crank build, they’re kind of similar with big bore and short strokes. I’m sure the low deck will spin quick and high.Not necessarily after fit. The lighter weight is a plus but, I’m mainly after engine characteristics. I LOVE the free spinning nature of the 340. I’m hoping to achieve the same characteristics with extra cubes for a bigger punch

Considering the low $5K budget, home porting OEM cylinder heads seems like the best option. Also @ .474 lift, the best and most gain you’ll find in flow is in the bowl area and short side. After that, I’m sure you’ll find gains in flow but not a lot and I’ll call it not worth the pursuit. Once you go up into the port, it’s focusing on high lift/flow areas.

I’d bet even a set of new valves would be within the budget and really help a lot.

Food for thought? Yea?

Contact member PRH for a tip on this.

What do you have for an intake?

Why not just build a 451 ? A few extra cubes won't hurt. My 451 spins like a small block and has lots of grunt.

It just seems the better one to build would be the 451 by dropping in the 440 crank.

Ron, I gotta tell ya, I agree but, since you whet the bigger is better, why didn’t you suggest a larger engine like a 470 or the big crank for a 498/500 or bigger ye 512 build?Why not just build a 451 ? A few extra cubes won't hurt. My 451 spins like a small block and has lots of grunt.

View attachment 1716116372

Not for nothing, he did state he knows about these set ups, he mentions in his video 440source.com about it. I know you watched the video right?

He also mentions he wants a to do something different which seems to be a problem for you and others. Why is that?

So a guy chooses to spend his money the way he wants to and tells everybody so and yet everyone side steps that noted comment by the builder and act as if it’s not a fact only to suggest spending his money on something he doesn’t want to do which is actually the waste of money.

Am I missing something here?

So far I get it’s not;

OK to be creative

Do something different

Spend your money the way you see fit

Have fun your way

But instead follow the herd;

Purchase what is popular (even though you don’t want to)

Do a build you don’t want to do

Etc….

I don’t get it. I do know it sucks doing things differently than what the herd does. Lord knows I got it on most every thing I did and do. Things like;

Run a MoPar

Run a small block

Use a TQ instead of a Holley

And the list goes on & on & on…..

The real waste of time is not doing what you want to do and follow others on what there doing and ignoring your inside and trying to be creative or different while having fun.

I get this crap **** from Chevy guys. They all have their list of reasons which boil down to the Chevy being popular and cheap.

If popular and cheap fit you, God bless you but don’t devil shame me for using what I want and not being of the same mind set especially being cheap and running what’s popular because it’s plentiful and cheap. Even more so just to save money.

Last edited:

slimjim

Well-Known Member

I’m trying to score a set of 915 heads which, is difficult to do here in CA. Ideally, I’ve got about $800 max to throw at the heads. New valves and maybe even valve seats would be priority if budget allowed.On a quick overview of the 340 to your offset low deck crank build, they’re kind of similar with big bore and short strokes. I’m sure the low deck will spin quick and high.

Considering the low $5K budget, home porting OEM cylinder heads seems like the best option. Also @ .474 lift, the best and most gain you’ll find in flow is in the bowl area and short side. After that, I’m sure you’ll find gains in flow but not a lot and I’ll call it not worth the pursuit. Once you go up into the port, it’s focusing on high lift/flow areas.

I’d bet even a set of new valves would be within the budget and really help a lot.

Food for thought? Yea?

Contact member PRH for a tip on this.

What do you have for an intake?

An you yourself or have you ported a head before?

WOW, a Red X for asking a question. Harsh. KimSo where did u get this kit? Do u have a link? Thanks. Kim

Yes. Only two stock strokes in B/RB. Old 361/383/400 all same stroke. There was an oddball RB 383, AKA same stroke as RBIs the 400 stroke the same as a 383? (Shorter than a small block Chevy) what is the stroker crank stroke.

All factory RB same stroke, 413, 426, 440

Bingo.

B engines, 350, 361, 383 & the 400 all have a 3.38 stroke.

RB engines, the odd ball 383, 413, 426 and the 440 all have the 3.75 stroke.

B engines, 350, 361, 383 & the 400 all have a 3.38 stroke.

RB engines, the odd ball 383, 413, 426 and the 440 all have the 3.75 stroke.

RAMM

Well-Known Member

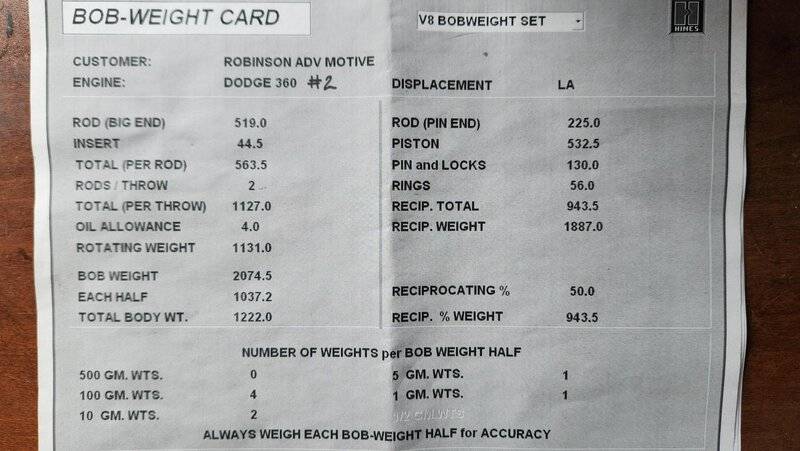

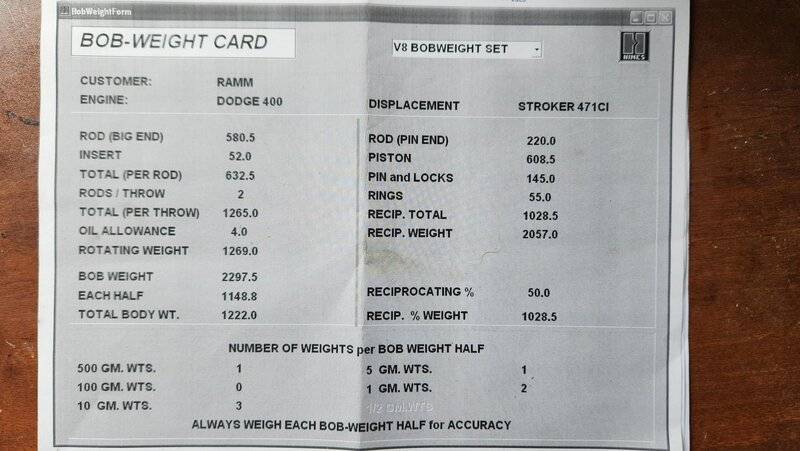

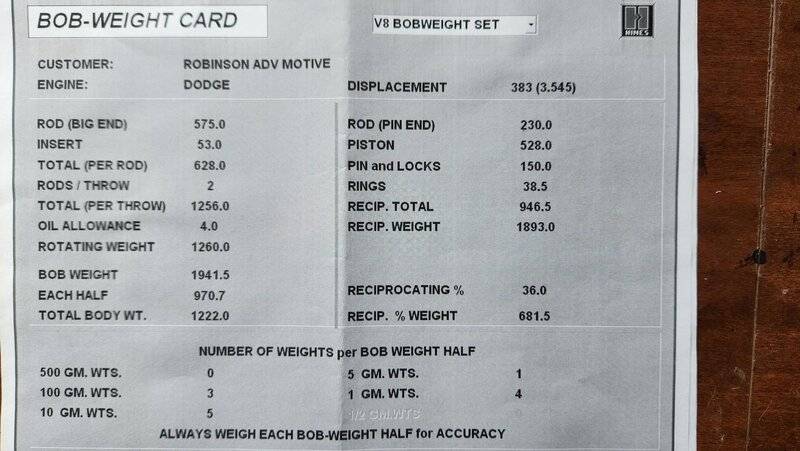

Interesting to look at some balancing information.

471 W/ ICON dished pistons and Eagle 6.535" Rods = 2297.5 Bobweight

360 W/KB Hypers and OEM Magnum Rods(lighter than an LA) = 2074.5 Bobweight

426 W/Mahle and Eagle 6.7 Rods = 1941.5 Bobweight

J.Rob

471 W/ ICON dished pistons and Eagle 6.535" Rods = 2297.5 Bobweight

360 W/KB Hypers and OEM Magnum Rods(lighter than an LA) = 2074.5 Bobweight

426 W/Mahle and Eagle 6.7 Rods = 1941.5 Bobweight

J.Rob

WHOA! Very nice.

slimjim

Well-Known Member

Finally got the short block assembled!

DIY Mopar 426 STROKER - FULL Short Block Assembly

DIY Mopar 426 STROKER - FULL Short Block Assembly

I love your build. Question. How much hp and rpm's do you think the 383 crank will hold after grinding and would a 440 crank ground the other way be stronger? I understand you would also have to grind the mains. Just wondering what the limits may be. Anyone's guess appreciated.Same stroke. Reason for the 383 crank is to get a forged unit. When the rod journals are offset ground it increases the stroke from 3.38 to 3.545. Rod journals are now 2.2”

Just do like I did when I was 16. Walk up to that beeotch on your time, chuck one up on it and start playin around. I went through 5 or 6 old 305 and 350 Chevy cranks and then I figured it out. ....but of course, you have to have a boss that will actually let you do that.My pussy boss needs to teach me how to use the crank grinder.

He's afraid the stone is going to blow up lol.Just do like I did when I was 16. Walk up to that beeotch on your time, chuck one up on it and start playin around. I went through 5 or 6 old 305 and 350 Chevy cranks and then I figured it out. ....but of course, you have to have a boss that will actually let you do that.

I do need to check the thing out for visual cracks.

That is a good idea, we have a lot of junk to practice on.

He'll let me ill just tell him I want to make him more money

What kind of grinder is it? The one I learned on was a Van Norman 477. I know there are way more "modern" machines now, but it was a nice old grinder and did a really good job. That old guy kept it in tip top condition. There were digital dial attachments available for it even back then (about 1980-81) but he swore he'd never get them and he never did. He said keeping "fresh" on reading analog dials and mics made a better machinist out of you and that the digital stuff made you lazy. lolHe's afraid the stone is going to blow up lol.

I do need to check the thing out for visual cracks.

That is a good idea, we have a lot of junk to practice on.

He'll let me ill just tell him I want to make him more money

Yeah I believe it is exactly.What kind of grinder is it? The one I learned on was a Van Norman 477. I know there are way more "modern" machines now, but it was a nice old grinder and did a really good job. That old guy kept it in tip top condition. There were digital dial attachments available for it even back then (about 1980-81) but he swore he'd never get them and he never did. He said keeping "fresh" on reading analog dials and mics made a better machinist out of you and that the digital stuff made you lazy. lol

I agree Im not a digital guy.

....and there's nothing wrong with the digital age, I'm not knocking it. There are some VERY sophisticated machines out there now. Snake had a point, though. I could roll a mic over anywhere in its travel and hand it to him and he'd rattle off what it was in a flat second. He was a retired WWII old Navy guy. I miss guys like him.Yeah I believe it is exactly.

I agree Im not a digital guy.

No there isn't anything wrong with digital.....and there's nothing wrong with the digital age, I'm not knocking it. There are some VERY sophisticated machines out there now. Snake had a point, though. I could roll a mic over anywhere in its travel and hand it to him and he'd rattle off what it was in a flat second. He was a retired WWII old Navy guy. I miss guys like him.

No matter how much of a small block Chevy circle track guy my boss is he has a wealth of knowledge ( which I don't ever equate with Chevy guys lol) and he gets pretty happy when I ask him questions or say hey, "is this how you would go about this? "

We're both old school type guys now if I can just get him away from "safe" size camshafts lol .

slimjim

Well-Known Member

I’m using off the shelf rods and pistons with my 426 combo.At least source a 440 crank and build a 451. Then it's a crank and a set of off the shelf pistons.

-

Similar threads

- Locked

- Replies

- 13

- Views

- 4K

- Locked

- Replies

- 1

- Views

- 664

- Replies

- 30

- Views

- 11K

- Replies

- 2

- Views

- 703

- Replies

- 0

- Views

- 125