Long overdue update!

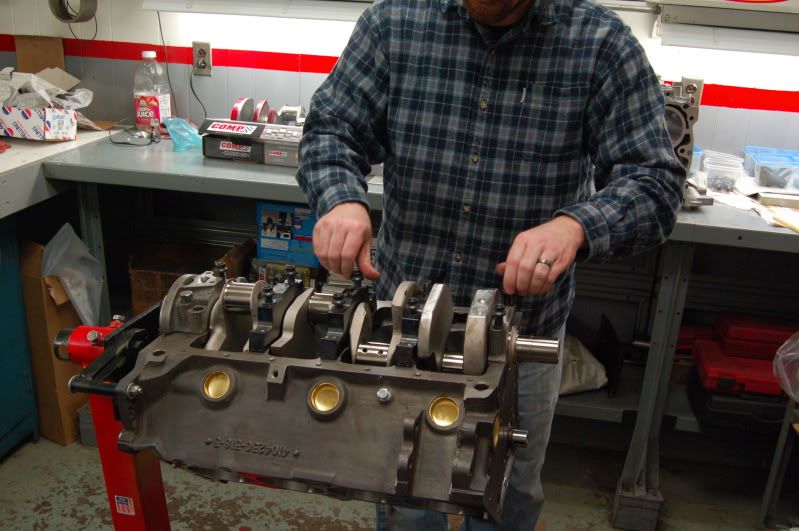

I've been plugging away at the motor, bottom end is assembled and we're getting on the top end soon... cant wait!

Both stock and ported eddy's were CC'd ( intake, exhaust, & chambers ) before we flowed them

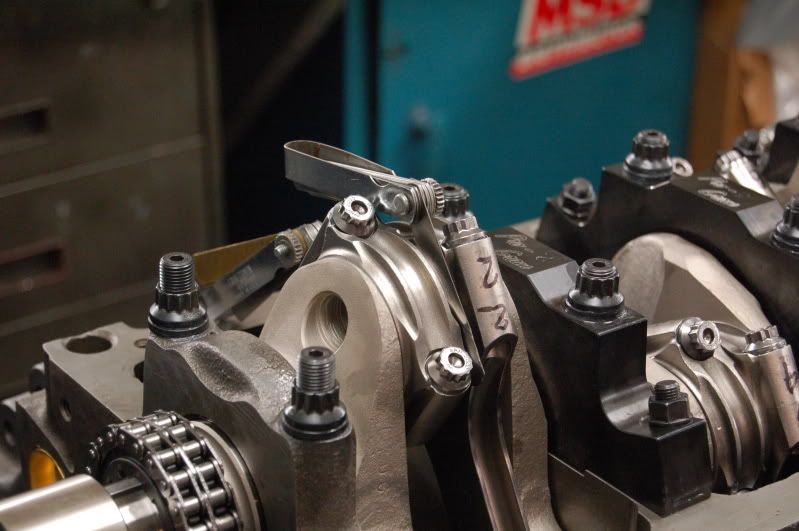

Also got the crank balanced - we needed almost 170 grams off both sides and instead of drilling the hell out of the crank we milled off the weight. There are a bunch of ways to get this done but this is a better result then the drill at that amount.

You can see this SBF was drilled to death - not the most professional way to get it done.

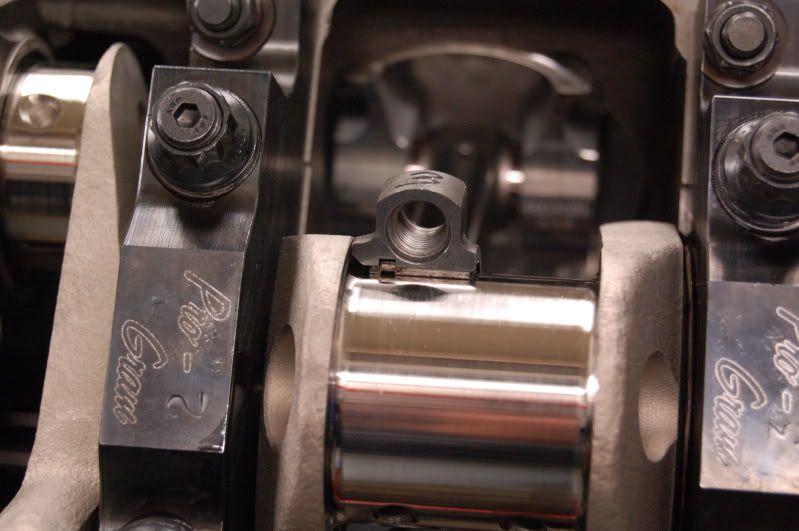

With assembly right around the corner I whittled away at the oil pump and passages - the filter area and rear cap took the most work - here is a progress shot.

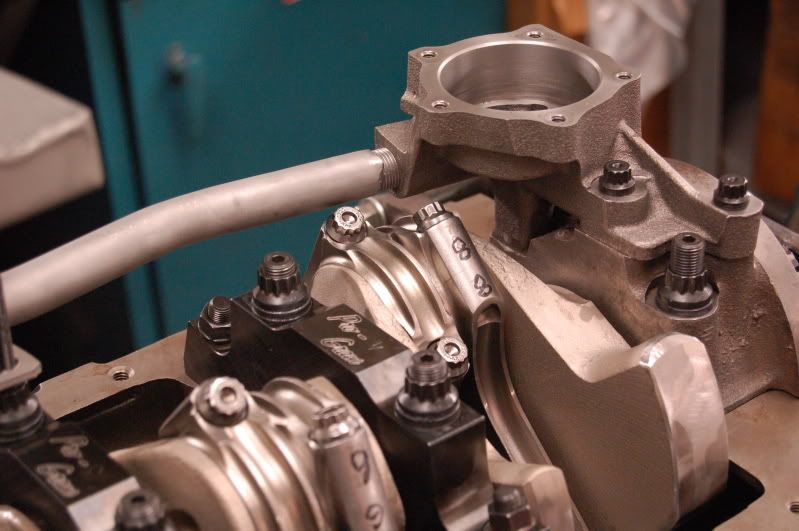

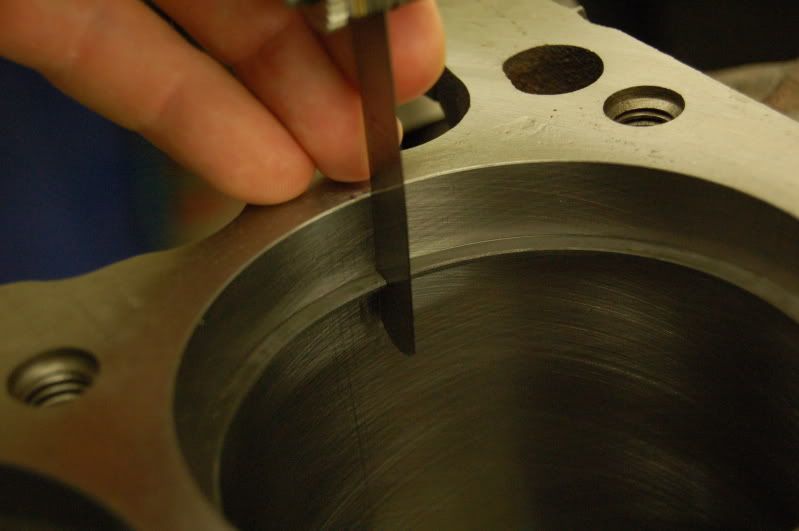

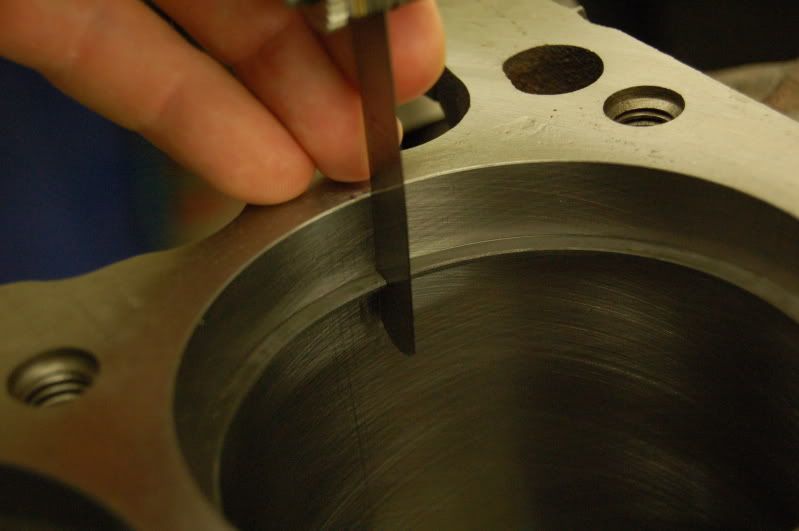

With everything clean we file fit the rings... getting there!

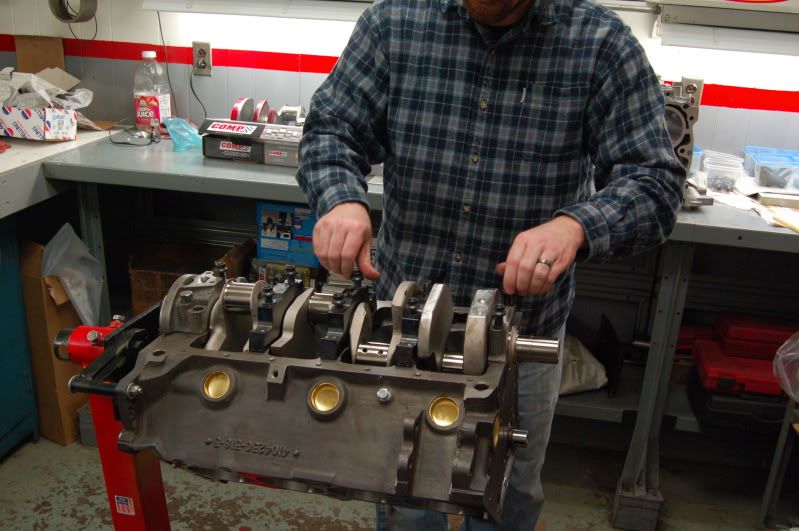

HOME SWEET HOME!!!

I've been plugging away at the motor, bottom end is assembled and we're getting on the top end soon... cant wait!

Both stock and ported eddy's were CC'd ( intake, exhaust, & chambers ) before we flowed them

Also got the crank balanced - we needed almost 170 grams off both sides and instead of drilling the hell out of the crank we milled off the weight. There are a bunch of ways to get this done but this is a better result then the drill at that amount.

You can see this SBF was drilled to death - not the most professional way to get it done.

With assembly right around the corner I whittled away at the oil pump and passages - the filter area and rear cap took the most work - here is a progress shot.

With everything clean we file fit the rings... getting there!

HOME SWEET HOME!!!