Funny how he says "another Red 65 Barracuda". How many can there be???

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

65 Barracuda daily driver

- Thread starter 65barracudaLA

- Start date

-

65barracudaLA

Well-Known Member

At least at the show it was the only red 65 Barracuda hahaFunny how he says "another Red 65 Barracuda". How many can there be???

65barracudaLA

Well-Known Member

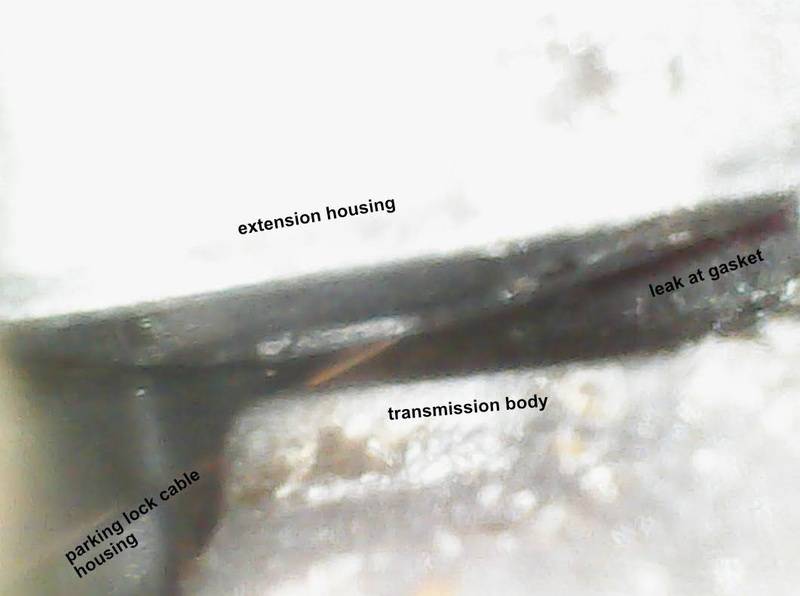

At least I figured out were the transmission fluid leak originates. No idea how to fix that though. I will post that in the transmission forum as well. I took my 10 dollar Amazon borescope and cleaned everything with brake clean. I didn't have to wait long to see it seeping out. Below you can see a screenshot. It's at the bottom of the extension housing gasket where its bolted to the transmission body. I might be just a bolt that needs to be tightened, but it appears you can only access the bolt from the inside of the parking lock cable housing. The transmission was fully rebuilt with all new gaskets (by someone else).

I still have the slant 6 a904 that was in the car before and I will take a look at that before I drain all the transmission fluid and start searching for a new parking lock cable housing gasket.

I still have the slant 6 a904 that was in the car before and I will take a look at that before I drain all the transmission fluid and start searching for a new parking lock cable housing gasket.

65barracudaLA

Well-Known Member

So I used some red RTV this time to fix the exhaust stud coolant leak. Haven't had a chance to test it yet because I drained the transmission fluid. I also used a longer bolt on the fuel pump and now it has more grip, so hopefully that oil leak it taken care of as well. I had already shimmed the engine on the passenger and adjusted the dual tti exhaust a bit more and now it's not touching anymore.

The transmission fluid leak is not addressed yet, but I think I figured out a way. I'm going to have to remove the park lock cable housing - otherwise there is no way to get to the leak. I got some transmission fluid RTV (which I didn't even know existed!). I'm going to clean it as good as I can and then just RTV around the gasket as much as I can. That's obviously not as effective as applying it to each side of the gasket and then bolting it together, but without taking out the transmission I don't see another way.

I still haven't really driven the car other than to Spring Fling and I'd love to daily drive it again as soon as possible.

Wish me luck!

The transmission fluid leak is not addressed yet, but I think I figured out a way. I'm going to have to remove the park lock cable housing - otherwise there is no way to get to the leak. I got some transmission fluid RTV (which I didn't even know existed!). I'm going to clean it as good as I can and then just RTV around the gasket as much as I can. That's obviously not as effective as applying it to each side of the gasket and then bolting it together, but without taking out the transmission I don't see another way.

I still haven't really driven the car other than to Spring Fling and I'd love to daily drive it again as soon as possible.

Wish me luck!

65barracudaLA

Well-Known Member

Long story short: The RTV didn't do a whole lot to stop the leak. Ended up making my own transmission diaper. Not pretty, but it works. The park lock cable snapped and I didn't want to spend 300 bucks and wait 3 weeks for one from Imperial Services. So I got this eyelet thing, had to shorten it on both sides, drill a new hole and crimped it the last 1/8" of cable that were sticking out. There is 1-1/8" between the park lock pivot and the bracket that holds the housing in place. The cable snapped at around 7/8" from the pivot and the groove is about 1/8" in, so that left 1/8" to engage. Probably not explaining it right, but it works!

Noticed that the shift cable is attached with wire and a zip tie. I wonder why, but I don't really want to mess with it, because it works. Just needs to be adjusted a bit, but on the transmission side.

Took her for a spin. Was pinging a bit, but advancing the timing helped. I'm a little confused, because I thought retarding the timing helped with pinging, but whatever works, right? Stoked to be able to drive my Barracuda again!

Noticed that the shift cable is attached with wire and a zip tie. I wonder why, but I don't really want to mess with it, because it works. Just needs to be adjusted a bit, but on the transmission side.

Took her for a spin. Was pinging a bit, but advancing the timing helped. I'm a little confused, because I thought retarding the timing helped with pinging, but whatever works, right? Stoked to be able to drive my Barracuda again!

65barracudaLA

Well-Known Member

So it turns out it might not be pinging, but has more of a lifter tick. It gets worse the more you step on it. There was also a tiny bit of white fluid on the back of the dipstick. I think that might be condensation. No oil in the coolant. The engine has been mostly sitting since February of last year and only fired up and driven sporadically since April or so. There was a lot of rain when the exhaust wasn't fully connected, so condensation is possible. At startup there is water vapor coming out of the exhaust. It could also come from the coolant leak at the exhaust manifold that is now fixed.

Anyways, I changed the oil and filter (and added some Marvel Mystery Oil - I don't think that does much, but just in case...).

It didn't change anything. It appears to be only coming from the driver side.

So now I think I might have to check or replace the lifters. On the old slant 6 ('83 hydraulic lifter engine) I replaced the lifters and that was pretty straight forward, but I've never done that on a small block. On the slant 6 I replaced all the lifters, but I'd prefer only to replace the bad ones this time.

How do you tell which ones are bad? Is there a way to test them once they are out of the engine?

Anyways, I changed the oil and filter (and added some Marvel Mystery Oil - I don't think that does much, but just in case...).

It didn't change anything. It appears to be only coming from the driver side.

So now I think I might have to check or replace the lifters. On the old slant 6 ('83 hydraulic lifter engine) I replaced the lifters and that was pretty straight forward, but I've never done that on a small block. On the slant 6 I replaced all the lifters, but I'd prefer only to replace the bad ones this time.

How do you tell which ones are bad? Is there a way to test them once they are out of the engine?

JDMopar

Well-Known Member

It might be a good idea to cut open the oil filter that you just removed to see if there is anything worrisome in it. Hopefully the engine hasn't wiped a cam lobe. You could also take the drivers side valve cover off, check to see if the rocker arm shaft is installed correctly. I forget if the notch is down in the front or rear on the drivers side head? Info should be easy to find in the smallblock section or in @krazykuda small block assembly tutorial on here. If that checks out, check for a bent pushrod or a rocker arm going bad. I've had them make pecking noise and found the pushrod end of the rocker cracked and the pushrod about to poke thru. Torn a few down that had a pushrod poked thru! If you take the coil wire off and spin the engine over with a screwdriver on the starter relay, you can watch the drivers side rocker arms and try to determine if they are all rising to the same height. If you see one or more that obviously isn't, pull the rockers off to see why. If the rocker looks ok and the pushrod isn't bent (roll it on a piece of glass) then it could be a wiped cam lobe. You can shine a light down thru the head and see. Sometimes it seems a vehicle wants to fight us every step we make. I've got an 04 Dodge Dakota that has done me that way. I think I have it beaten into submission though, so don't give up!

are you sure it's lifter tick and not an exhaust leak there at the manifold?

JDMopar

Well-Known Member

Good point! If his motor has heads that have the air bleed holes, the factory manifold hits the head under #7 cylinder exhaust port and won't seal up. Some are worse than others. The 302 heads on my 273 would probably crack the manifold if it were cranked down without grinding clearance. The Dougs D450's clear just fine!

or as simple as something like a loose or warped manifold...Good point! If his motor has heads that have the air bleed holes, the factory manifold hits the head under #7 cylinder exhaust port and won't seal up. Some are worse than others. The 302 heads on my 273 would probably crack the manifold if it were cranked down without grinding clearance. The Dougs D450's clear just fine!

65barracudaLA

Well-Known Member

Thanks for the advice, I'm gonna check the lifters when I have a moment. This engine swap is not going as planned at all, but at least I'm learning a lot (about small blocks) haha. It's been almost a year since the slant came out. The engine previously had late 60s exhaust manifolds on it, so the head was already ground down and I ground it a bit more, but I'll check the clearance again. It just doesn't sound like something like that, though. I have some '67 closed chamber 273 heads that I'd love to swap in, but those heads will probably need to go to a machine shop. Anyways, I hope I can figure this out soon and start daily driving the car again!

The advice on double checking for an exhaust leak is good. Definitely make sure before tearing into your engine.

The engine previously had late 60s exhaust manifolds on it, so the head was already ground down and I ground it a bit more, but I'll check the clearance again.

explain "the head was already ground down" please and thank you.

Richard Sweet

Well-Known Member

If this engine has solid lifters and adjustable rockers, I'd check all the valve clearance settings first. Of course if one is gapped too wide, it will be noisy. Keep an eye on the adjusting screws and make sure that they have the proper drag and are not loose fitting.

(From post 666, I see that your engine has non-adjustable rockers for hydraulic (not solid) lifters).

(From post 666, I see that your engine has non-adjustable rockers for hydraulic (not solid) lifters).

Last edited:

65barracudaLA

Well-Known Member

explain "the head was already ground down" please and thank you.

As you can see that pad under the exhaust port had already been ground down by a previous owner to clear the manifold. The engine was in a '68 Dart before and the manifold is a bit different. The early manifolds appear to need more room, so I ground it down more.

Last edited:

65barracudaLA

Well-Known Member

So I took a little video to see whether the rockers move evenly and it appears they do?!

There is a bit of a grey on the dipstick when you wipe off the oil, so that worries me a little bit. On the other hand, I have driven the car less than a hundred miles with the new engine. I wonder if that's enough to completely wipe out a cam lobe?!

Anyways, I'll take off the rockers next to inspect the push rods. It looks a lot more complicated to get the lifters out than on the slant though...

There is a bit of a grey on the dipstick when you wipe off the oil, so that worries me a little bit. On the other hand, I have driven the car less than a hundred miles with the new engine. I wonder if that's enough to completely wipe out a cam lobe?!

Anyways, I'll take off the rockers next to inspect the push rods. It looks a lot more complicated to get the lifters out than on the slant though...

JDMopar

Well-Known Member

Did you wipe the oil out of the valve end of the rockers before the video, to keep it from getting slung out? If you didn't, there should be more oil in them, I think. If you pull the rocker arm assembly off, you can then check to see if oil is getting to the head on that side. Look down into the holes that the rocker shaft bolts go into in the head. Either the 2nd one from the front or the second one from the back will have 2 holes. One straight down for the rocker shaft bolt and the other one is a little smaller and goes at an angle. That one is the one oil should squirt out of to oil that rocker shaft. The hole in the bottom of the rocker shaft should be slightly bigger at that hole so oil can get by the bolt, up into the shaft, and then thru the little holes in the bottom of the shaft that line up with rocker arms. The bottoms of the rockers have a groove in them to let the oil get all the way around. I don't think I would crank it over without the rockers and pushrods in place to see if it oils. If you have an oil pump priming tool, you could remove the oil pump/distributer drive and do it with a drill. You would need to remove all the spark plugs so you can turn the motor over by hand with the drill running the oil pump. I'm gonna quit before someone calls me AJ....lol.

JDMopar

Well-Known Member

See AJ's post #5 in the thread linked below, about which way the notch in the bottom of one end of the rocker shaft should go. It points down, and is on the drivers side front of the head and the passenger side rear.

www.forabodiesonly.com

www.forabodiesonly.com

Stock 340 Rocker Arm Order

I have 34LT and 35 RT rocker arms on the 340 I am rebuilding after someone else had it torn apart. I am told the notch in the rocker arm shaft goes to the front of the left head and to the rear on the right head. Does anyone know what order the rocker arms go on from front to back on each...

www.forabodiesonly.com

www.forabodiesonly.com

65barracudaLA

Well-Known Member

They were all covered in oil, I just wiped it off to keep the mess to a minimum. The rockers were already assembled when I bought the engine, but I'll double check. I haven't taken off the rockers yet, but will do that now. If the pushrods look okay, I'll probably take off the intake before spending hours trying to get to the lifters some other way.Did you wipe the oil out of the valve end of the rockers before the video, to keep it from getting slung out? If you didn't, there should be more oil in them, I think. If you pull the rocker arm assembly off, you can then check to see if oil is getting to the head on that side. Look down into the holes that the rocker shaft bolts go into in the head. Either the 2nd one from the front or the second one from the back will have 2 holes. One straight down for the rocker shaft bolt and the other one is a little smaller and goes at an angle. That one is the one oil should squirt out of to oil that rocker shaft. The hole in the bottom of the rocker shaft should be slightly bigger at that hole so oil can get by the bolt, up into the shaft, and then thru the little holes in the bottom of the shaft that line up with rocker arms. The bottoms of the rockers have a groove in them to let the oil get all the way around. I don't think I would crank it over without the rockers and pushrods in place to see if it oils. If you have an oil pump priming tool, you could remove the oil pump/distributer drive and do it with a drill. You would need to remove all the spark plugs so you can turn the motor over by hand with the drill running the oil pump. I'm gonna quit before someone calls me AJ....lol.

JDMopar

Well-Known Member

They are more than likely oiling correctly then since you had to wipe it out. There is a tool made to pick lifters out with, but they are just so-so to use and the lifters fall off of it half the time. A magnet works just as good, stuck to a long screwdriver. In my experience with that task, you waste as much time trying to retrieve them after dropping them as you would have spent removing the intake so you can get to them. If you have a piece of flat glass, or a nice flat counter top you can roll the push rods on, if any are bent they will be easy to find. Slightest wobble is easy to see.

65barracudaLA

Well-Known Member

Pushrods are out. I don't have a glass table, but an extra quarter window... They all seem to have a slight wobble, which is more audible than visible:

I haven't cleaned all of them, but there is also some discoloration on them from heat?!

With the rockers and pushrods out of the way the lifters look a little more accessible. Will give it a shot, if it's a pain to get them in, I can still pull the intake.

I haven't cleaned all of them, but there is also some discoloration on them from heat?!

With the rockers and pushrods out of the way the lifters look a little more accessible. Will give it a shot, if it's a pain to get them in, I can still pull the intake.

JDMopar

Well-Known Member

They don't sound bent. I bet if you clean em up good with a scotchbrite pad they will sound different. Did the areas on the rockers where the pushrods contact them look ok?

65barracudaLA

Well-Known Member

I haven't taken out the lifters completely, but I've been able to look at the bottom side of most of them and I can't see any wear on them. They look almost new. I forgot to check the rocker arms, but will do tomorrow.

On the slant I replaced all the lifters without really checking them, but it solved the problem aka it stopped the ticking. Could they just be bad internally? And how do you test that? I've been looking here on FABO, but haven't found an answer yet. Will keep looking.

JDMopar

Well-Known Member

Honestly, I've never had to check lifters. I've just replaced them when I pulled a motor apart and rebuilt it with a new cam/lifter set. You could check the tension of the internal spring if you had a piece of round rod you could round the end on and stick it down thru each pushrod hole and see if any feel weaker than others. If you're not having any trouble getting them out with that magnet, pull them out one at a time and check em on the bench. You might even be able to disassemble them and clean them internally and then relube them and put them back together and re-install them one at a time so you don't mix them up in their respective bores. It's a pain trying to see how to get them lined up on the magnet to pull them out, but it's do-able. I replaced a cam that way once upon a time, without pulling the intake. Somebody told me I couldn't do it.....lol.

sireland67

Well-Known Member

Ticking as the engine is reved higher, or put under load, sounds like an exhaust leak not a lifter.

-