Yep, I’m doing what I know I can do without the body screaming at me and the dash is one of them. I had to call in some favors owed me by my bodyman friend to finish both the passenger and driver’s side quarter panels; the hips just aren’t cooperating right now. Just trying to work smart!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

65 Dart Wagon Conversion to a Sedan Delivery

- Thread starter 65 Dartman

- Start date

-

JDMopar

Well-Known Member

I started to assemble the dash today by assembling and adjusting the glove box lid to its hinges with new hardware. I will need new glovebox lid bumpers. The 2 holes seen in the pic is 2 of the 4 holes needed for the plastic maintenance card that’s pop riveted to the lid. Got to find some short rivets due to the depth between the 2 halves. The same hardware is used to secure the trim for the glovebox and end panel trim.

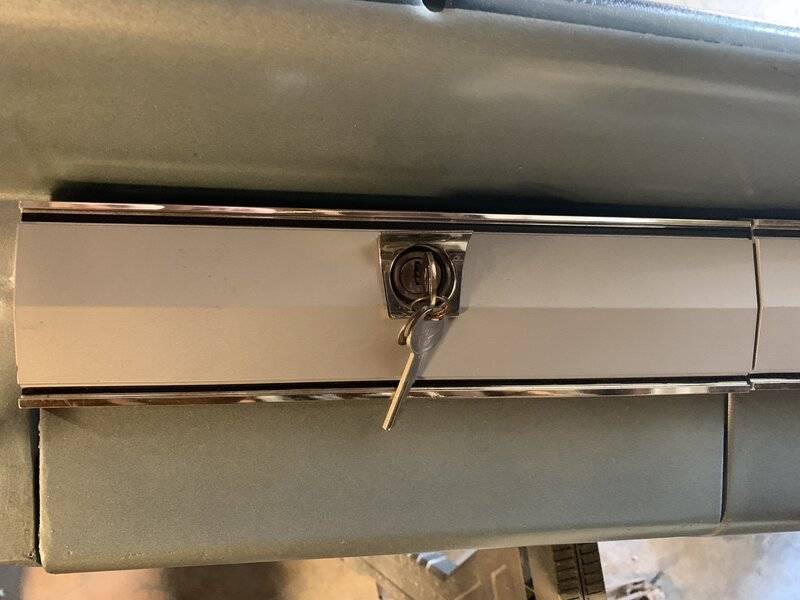

I found in my storage a NOS glovebox lock assembly and installed it.

I also found a NOS lighter assembly which included a NOS bezel that says, what else but LIGHTER.. We don’t smoke so it’ll be used for charging cell phones or whatever will plug in. That goes in the center panel on the right side next to the glovebox. Also in that panel is the passenger and driver’s heated seats controls. In between them are some idiot lights i found online for DOOR AJAR and FASTEN SEATBELTS. On the left is the rear power window switch and bezel

Under the instrument panel area are a pair of momentary switches used to set up the parameters for the instruments in the Dakota Digital cluster.

Still to install are the NOS headlight switch and NOS early A variable speed wiper Switch and glovebox. I decided not to install the instrument cluster until I get the headlight and wiper switches, the center midrange and outer tweeter speakers installed on top along with their wiring and get the dash harness installed and hooked up to the various switches and components. Without the cluster and glove box it gives me the added room to get my hands in there

I found in my storage a NOS glovebox lock assembly and installed it.

I also found a NOS lighter assembly which included a NOS bezel that says, what else but LIGHTER.. We don’t smoke so it’ll be used for charging cell phones or whatever will plug in. That goes in the center panel on the right side next to the glovebox. Also in that panel is the passenger and driver’s heated seats controls. In between them are some idiot lights i found online for DOOR AJAR and FASTEN SEATBELTS. On the left is the rear power window switch and bezel

Under the instrument panel area are a pair of momentary switches used to set up the parameters for the instruments in the Dakota Digital cluster.

Still to install are the NOS headlight switch and NOS early A variable speed wiper Switch and glovebox. I decided not to install the instrument cluster until I get the headlight and wiper switches, the center midrange and outer tweeter speakers installed on top along with their wiring and get the dash harness installed and hooked up to the various switches and components. Without the cluster and glove box it gives me the added room to get my hands in there

Since I will be installing an A500, i needed an On/OFF switch to turn the Overdrive off when needed. I found a company in Australia - Billet Specialties- that does custom billet specialty switches. I ordered their 28mm ON/OFF switch with O/D engraved on the button. The 28mm is the size if the hole needed to install it. The button’s LED can be wired to light up when on or off. The bezel is about the same size as the OEM headlight and wiper bezels

EDIT: i figured the switch ought to be on the left side of the dash as that’s what I’m used to on my Dakota. It’s a little cramped under the factory switches but it will work just fine.

EDIT: i figured the switch ought to be on the left side of the dash as that’s what I’m used to on my Dakota. It’s a little cramped under the factory switches but it will work just fine.

Last edited:

If you want the lock up converter to work you’ll need another switch to lock it and a circuit to unlock it and the o/d when the brakes are applied .

Without turning the lock up converter or the o/d off manually every time you come to a stop it will bog the engine down to almost killing it before the trans comes out of o/d on its own.

If the switches are left on the converter will lock up when shifting into second and the o/d will engage when in third and hits 45 mph .

BTW when engaging the lock up converter it feels like a shift . DON’T do this at anything over light throttle repeatedly or you get to replace the converter and hope none of the converter clutch lining contaminated the rest of the transmission. Ask me how I know .

If I put o/d in my dart it will be a Gear Vendors unit .

I put one in my Avalanche behind 4L60E and later I installed it in my Tahoe behind 4L60 with just buying the trans adapter .

If I decide to put it in my Dart it’s just a mater of the trans adapter . No floor mods needed.

Without turning the lock up converter or the o/d off manually every time you come to a stop it will bog the engine down to almost killing it before the trans comes out of o/d on its own.

If the switches are left on the converter will lock up when shifting into second and the o/d will engage when in third and hits 45 mph .

BTW when engaging the lock up converter it feels like a shift . DON’T do this at anything over light throttle repeatedly or you get to replace the converter and hope none of the converter clutch lining contaminated the rest of the transmission. Ask me how I know .

If I put o/d in my dart it will be a Gear Vendors unit .

I put one in my Avalanche behind 4L60E and later I installed it in my Tahoe behind 4L60 with just buying the trans adapter .

If I decide to put it in my Dart it’s just a mater of the trans adapter . No floor mods needed.

Last edited:

Thanks for the comments. I’ll be using the pressure switches from PATC with the OD On/Off switch In the OD electric circuit as described on their website.

Last edited:

Cool .

What’s their web url ?

What’s their web url ?

it's transmissioncenter.net You’ll have to run a search to find the 500/518 conversion. I’ve got it bookmarked to come up on that page for reference especially the wiring since that’s what I’m working on for the dash and engine compartment.

JDMopar

Well-Known Member

If you want the lock up converter to work you’ll need another switch to lock it and a circuit to unlock it and the o/d when the brakes are applied .

Without turning the lock up converter or the o/d off manually every time you come to a stop it will bog the engine down to almost killing it before the trans comes out of o/d on its own.

If the switches are left on the converter will lock up when shifting into second and the o/d will engage when in third and hits 45 mph .

BTW when engaging the lock up converter it feels like a shift . DON’T do this at anything over light throttle repeatedly or you get to replace the converter and hope none of the converter clutch lining contaminated the rest of the transmission. Ask me how I know .

If I put o/d in my dart it will be a Gear Vendors unit .

I put one in my Avalanche behind 4L60E and later I installed it in my Tahoe behind 4L60 with just buying the trans adapter .

If I decide to put it in my Dart it’s just a mater of the trans adapter . No floor mods needed.

I wouldn't be so sure about no floor mods for the GV. I put one in a 71 Challenger a few years ago, and had to beat the living hell out of the tunnel to get clearance! An early A tunnel is smaller than an E body tunnel...so do your home work before plunking down the money for a GV.

Hey,

Is your O/D button a momentary switch or a "click on, click off" style. Only asking because I'm going to need to do the same for my A518

Is your O/D button a momentary switch or a "click on, click off" style. Only asking because I'm going to need to do the same for my A518

Hey,

Is your O/D button a momentary switch or a "click on, click off" style. Only asking because I'm going to need to do the same for my A518

it’s a click on click off switch. I will wire it so it’s on all the time like my Dakota. Click it once and it will come out of LU and OD. Click again and back into LU and OD

The switches I ordered from PATC lets the OD come in at 42 or 45MPH and the LU at 52. They also have adjustable pressure switches where you dial in yourself when you want each one to engage. I have them as well so might try both.

My buddy finished the passenger quarter the other day

and stopped by while I was working on the passenger door (taking a break from working on the underdash wiring harness. He said he’d trade his bodyman expertise for my help in putting an underdash and engine harness in his 78 truck. Good deal for both of us as he had that deer in the road look watching me with my custom harness and I’m not the fastest with bodywork. So he knocked out the passenger door and got it in primer in about an hour or so

and stopped by while I was working on the passenger door (taking a break from working on the underdash wiring harness. He said he’d trade his bodyman expertise for my help in putting an underdash and engine harness in his 78 truck. Good deal for both of us as he had that deer in the road look watching me with my custom harness and I’m not the fastest with bodywork. So he knocked out the passenger door and got it in primer in about an hour or so

If I can coordinate a day this week with my bodyman friend, maybe he might be able to knock out the passenger fender in short order. Well, maybe not in short order as the bottom of the fender needs replacing. I did buy both lower fender repair panels from Layson - thanks Rick@Layson for confirming they were in stock. I test fit the driver’s one and it was a decent fit!

EDIT: and of course forgot to add the picture! Of the patch panel! Yes, that’s a dent where i dropped a good size vice grips on it.

EDIT: and of course forgot to add the picture! Of the patch panel! Yes, that’s a dent where i dropped a good size vice grips on it.

Last edited:

JDMopar

Well-Known Member

Now that I found that and welded the deck where it was broke, it lives to die another day...and it saved me $2K on a new Cub Cadet!

Now that I found that and welded the deck where it was broke, it lives to die another day...and it saved me $2K on a new Cub Cadet!The

The vise grips was a good size type to hold decent size parts together and it just didn’t slip out of my hand. It slipped and i grabbed at it making it go higher in the air and as i tried to grab it on the way down, all I did was make it fall harder and faster! A little hammer/dolly work will fix that right up and even I can handle that lol.

Dang! Did you drop the vice grips off the top of the house?!?! LOL

. I'm sure your buddy can work that dent out pretty easily before installing the patch. We all make goof ups, so you're not alone!

The vise grips was a good size type to hold decent size parts together and it just didn’t slip out of my hand. It slipped and i grabbed at it making it go higher in the air and as i tried to grab it on the way down, all I did was make it fall harder and faster! A little hammer/dolly work will fix that right up and even I can handle that lol.

My bodyman friend showed up for a couple of days last week and knocked out both front fenders after the sandblaster guy took care of the inside of both fenders, the inside of the front lower valance, hood hinges and all 4 Of the taillight housings. I definitely need a blast cabinet for this small stuff!. We started on the driver’s side inside panel since this is definitely a 2 person job. Had to make sure the opening on the panel was correct for the shoulder belts I’m adding to the front. Got the panel spot welded in place - thank you Eastwood’s flanger/hole punch - and got the passenger side ready to weld in - except ran out of welding gas. Will get the gas tomorrow and get the panel knocked out. My wife commented there will be an awful lot of blue in the back!

Got a bit accomplished yesterday - bent some 1/8th inch flat stock, fabricated and welded the front and both side mounts to a tunnel support for a buddy seat AKA an armrest. The buddy seat is from a 68 B Body and fits just fine between the 66 narrow buckets

With me assisting my bodyman friend, got a lot accomplished - got the passenger side top inner panel spot welded in place, welds ground on both the driver and passenger top inner panel and a skim coat of filler applied and sanded over each weld. you can see way in the back where i need to fabricate the compound curve end panel.

I’m a pretty fair metal fabricator So got the driver’s side extreme rear panel At the D pillar bent on an inside curve, fitted, cut out for the rear cargo lights (which will be a pair of 64/66 side courtesy lights) and welded in place. We’ll start on the passenger extreme rear panel tomorrow.

With me assisting my bodyman friend, got a lot accomplished - got the passenger side top inner panel spot welded in place, welds ground on both the driver and passenger top inner panel and a skim coat of filler applied and sanded over each weld. you can see way in the back where i need to fabricate the compound curve end panel.

I’m a pretty fair metal fabricator So got the driver’s side extreme rear panel At the D pillar bent on an inside curve, fitted, cut out for the rear cargo lights (which will be a pair of 64/66 side courtesy lights) and welded in place. We’ll start on the passenger extreme rear panel tomorrow.

Got the passenger side rear inside panel fabricated, spot welded in place, ground and skim coat of filler applied to both sides. The hole on the right side is for the Rear courtesy light housing. I put aluminum foil Over the wiring and housing on the driver’s side covers Will protect the wiring and housing when the inside is painted I will install the rest of the wiring after paint is completed.

The sandblaster guy started on the rear and got part of the Body tailgate area done but had to stop - rain and sand don’t mix! He pointed the tailgate jam is gonna need some work - a smattering of rust through - all on the driver’s side that was under the seal. More fabrication.

The sandblaster guy started on the rear and got part of the Body tailgate area done but had to stop - rain and sand don’t mix! He pointed the tailgate jam is gonna need some work - a smattering of rust through - all on the driver’s side that was under the seal. More fabrication.

You're doing great Don! Will it be just two seats in the front? In that case you a d Judy can go camping with your delivery!! Cool!Got the passenger side rear inside panel fabricated, spot welded in place, ground and skim coat of filler applied to both sides. The hole on the right side is for the Rear courtesy light housing. I put aluminum foil Over the wiring and housing on the driver’s side covers Will protect the wiring and housing when the inside is painted I will install the rest of the wiring after paint is completed.View attachment 1715580918

View attachment 1715580919

The sandblaster guy started on the rear and got part of the Body tailgate area done but had to stop - rain and sand don’t mix! He pointed the tailgate jam is gonna need some work - a smattering of rust through - all on the driver’s side that was under the seal. More fabrication.View attachment 1715580925

You've done a great work with the rust issues! Is it any more except on the picture?

You're doing great Don! Will it be just two seats in the front? In that case you a d Judy can go camping with your delivery!! Cool!

A pair of 66 buckets with the buddy seat -I mean folddown armrest - and the standard stock Barracuda folddown rear seat - which I anticipate will be left in the down position all the time. All upholstered in the 66 Pattern in the 65 light blue metallic color.

Camping - with 3 dogs no camping. She does go camping with her daughter though with me dog sitting!

“65dartcharger said:You’ve done a great work with the rust issues! Is it any more except on the picture?

As far as I can tell, this is the last of it - thank goodness!

Last edited:

You've done a great work with the rust issues! Is it any more except on the picture?

Looking back on the rust issues, it was the driver and passenger front floors, the passenger rear floor, passenger A Pillar, both rear lower quarter panels and both lower rear front fenders - luckily there are repair panels for these commonly rusted areas! Unfortunately no repair panel for this last but of rust damage! The other stuff - swap to an AC firewall and 2 door sedan delivery conversion is all because that was my vision from the start!

-

Similar threads

- Replies

- 2

- Views

- 141

- Replies

- 8

- Views

- 321

- Replies

- 38

- Views

- 1K