It looks right. I'll be ordering the corresponding throttle cable too. Thanks again!On non stock applications etc the summit kickdown cable is the way to go. Trying to find the stock rod and bellcrank arrangements and making it work with non stock intakes and carbs is impossible, and that stuff is hard to find anymore, and can get expensive. Best left to the resto crowd.

You should double check that part number to be sure though

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

66 Dart GT HT Whatsitgonnabe?

- Thread starter 360DartGT66

- Start date

-

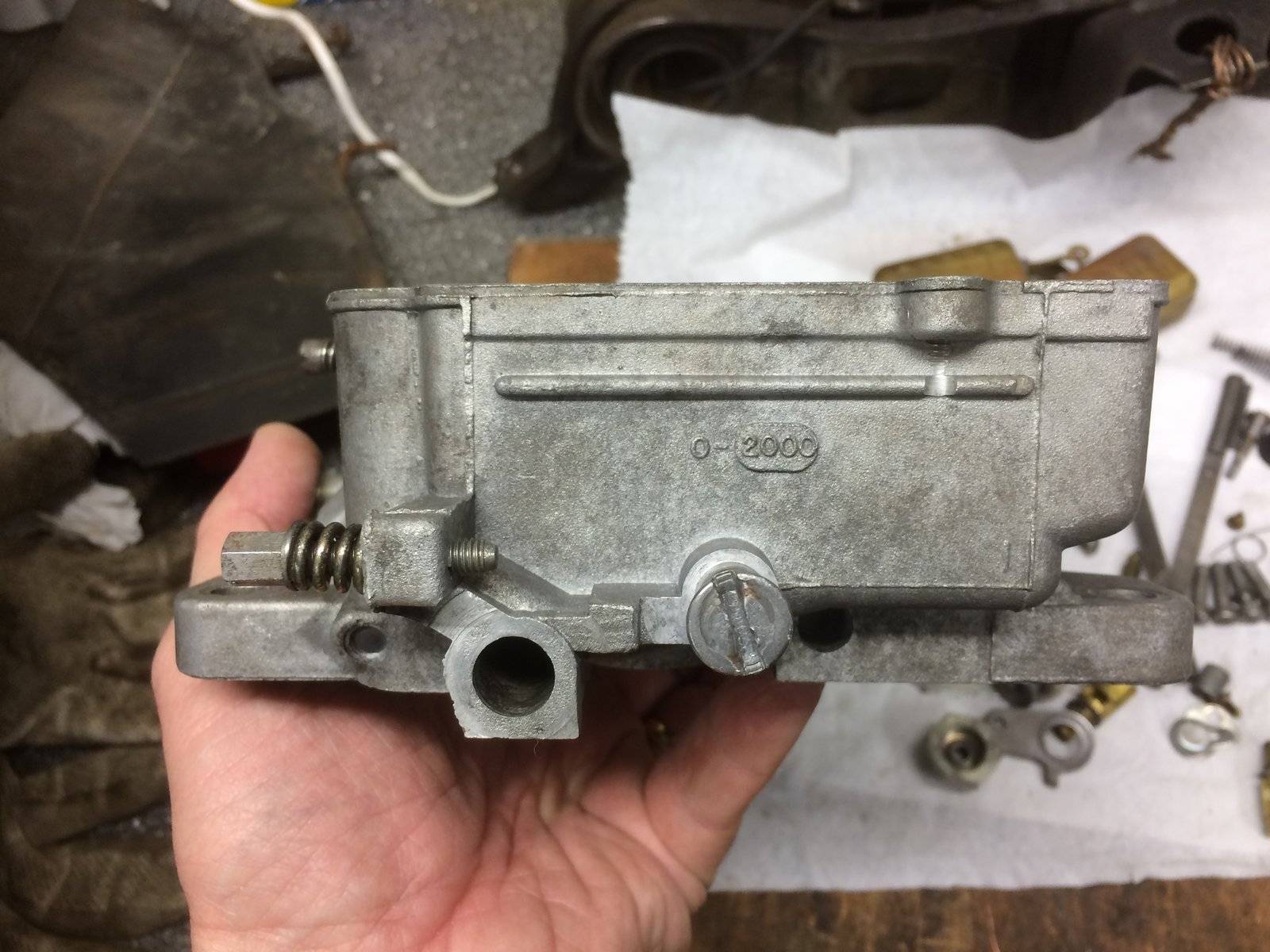

I've placed a couple of orders in the States, one with Carburetor Rebuilds Carburetor Restorations Carburetor Repairs. I bought a reamer/drill bit and some bushings for the main shaft of the AVS I just got. I also got a rebuild kit from them along with a set of screws for the butterflies. Great people to deal with! I had a ton of correspondence with them and they were great!

Summit will have the great honor of supplying me with new frame bump stops for the UCA:s, throttle cable, kick-down cable, a master cylinder rebuild kit (for the power brake assembly I got at the auction a few months back) and a brake booster check valve kit (for the same deal).

The stuff will go through halifaxhops.

Oh, and @jaws offered me a free junk AVS so I can take the missing linkage from it. I am much obliged, jaws! It, too, will pass by halifaxhops and he'll be gutting it, removing anything useful but discarding the housing which will only add weight.

Summit will have the great honor of supplying me with new frame bump stops for the UCA:s, throttle cable, kick-down cable, a master cylinder rebuild kit (for the power brake assembly I got at the auction a few months back) and a brake booster check valve kit (for the same deal).

The stuff will go through halifaxhops.

Oh, and @jaws offered me a free junk AVS so I can take the missing linkage from it. I am much obliged, jaws! It, too, will pass by halifaxhops and he'll be gutting it, removing anything useful but discarding the housing which will only add weight.

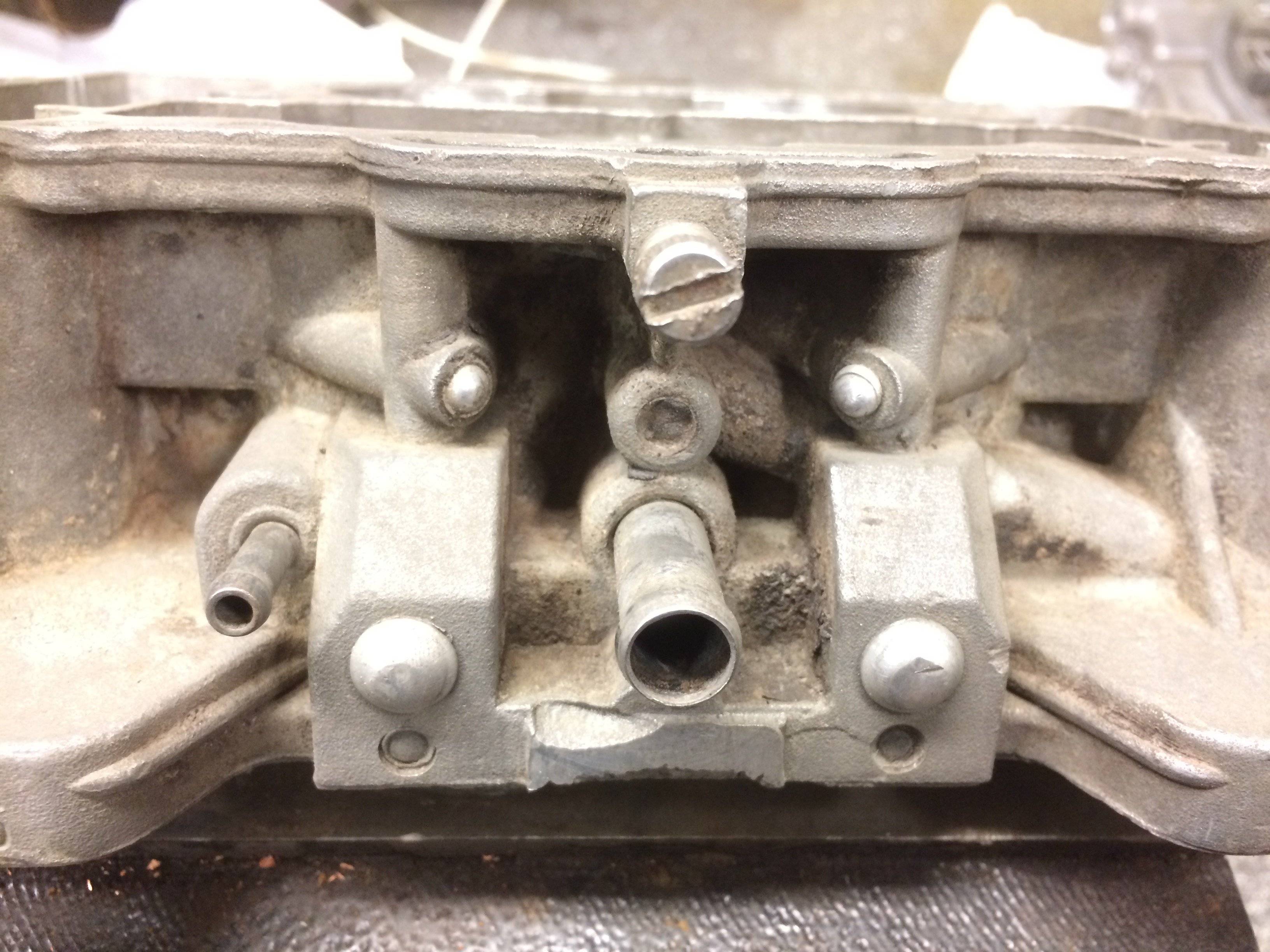

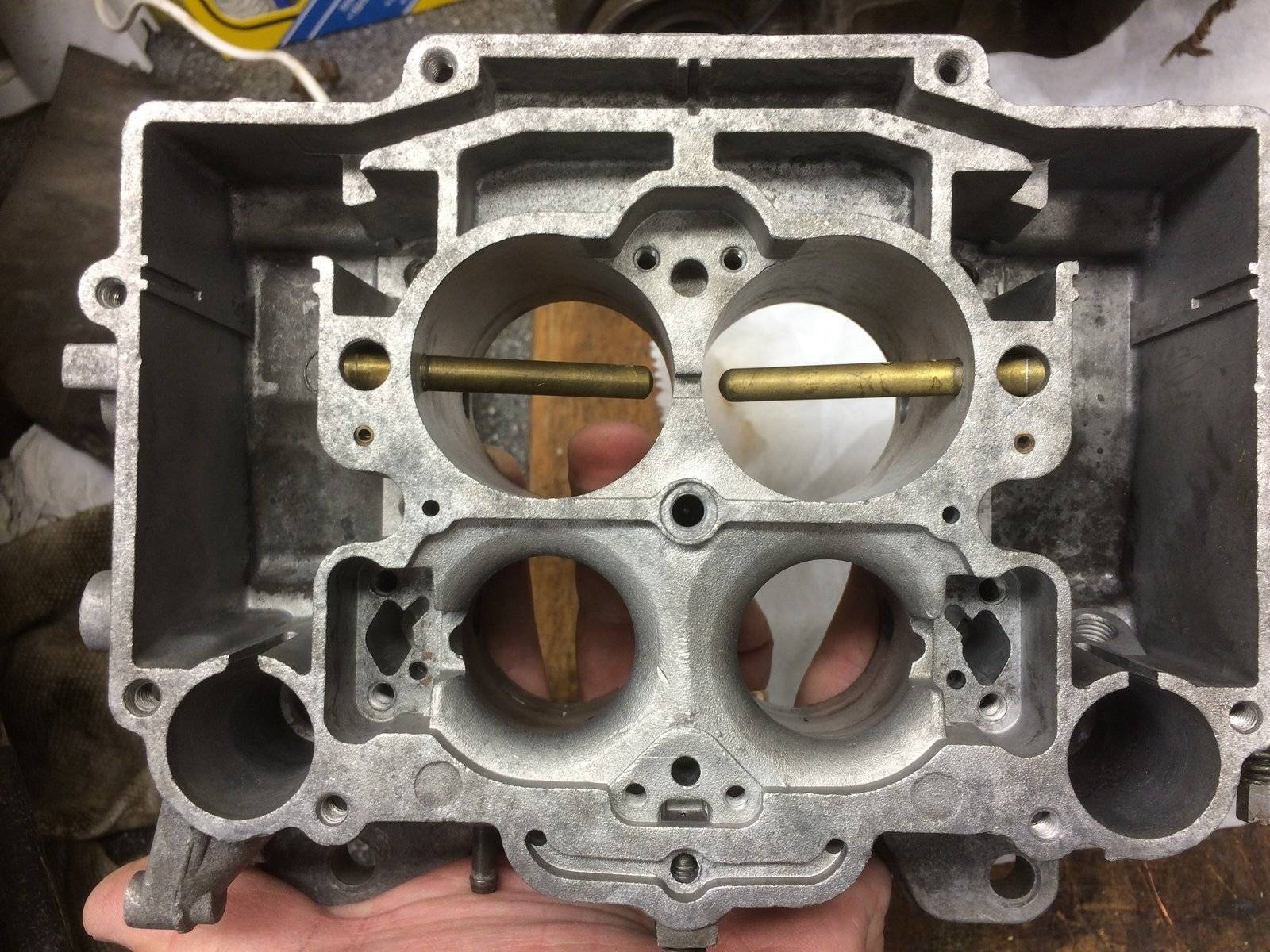

Day before yesterday I cleaned the parts in the base of the AVS, all but the base itself. It is very sooty so I think it's had its fair share of carb fires.

The internal parts actually came out pretty nice:

As you can see, I managed to bend one of the metering rods but I'll get 'new' ones from the jaws carb.

I'm thinking of glass bead blasting the case to remove all the stubborn crap on the outside. We'll see. The housing isn't really oxidized that much. There's just a lot of caked crud on it.

The internal parts actually came out pretty nice:

As you can see, I managed to bend one of the metering rods but I'll get 'new' ones from the jaws carb.

I'm thinking of glass bead blasting the case to remove all the stubborn crap on the outside. We'll see. The housing isn't really oxidized that much. There's just a lot of caked crud on it.

I have blasting soda in my ears ... This is how it turned out. The cool thing about soda blasting is that it dissolves in water.

Nice now just pop those plugs off to get at the adjustment screws. Want new ones? I prob have them but better to leave them off.

You mean the covers? Nah, I'll leave them off, I think. If a prospective buyer wants it to look OEM, they can add them themselves.

People, I seem to be out of luck on the rebuild kit for the master cylinder I got in the Tom&Dee auction back in April. If anyone of you happen to have a rebuild kit laying around, please take the time to look at my Wanted ad:

[WANTED] - Raybestos MK697 or equivalent M/C Rebuild Kit

[WANTED] - Raybestos MK697 or equivalent M/C Rebuild Kit

1967 'cuda

Dropped on Head as a Baby

People, I seem to be out of luck on the rebuild kit for the master cylinder I got in the Tom&Dee auction back in April. If anyone of you happen to have a rebuild kit laying around, please take the time to look at my Wanted ad:

[WANTED] - Raybestos MK697 or equivalent M/C Rebuild Kit

I just checked Summit's site a minute ago and it shows it available and will ship tomorrow. Hmmm...

I placed an order there and got everything but this kit right away. After a week I contacted them and the - very friendly - reply I got was that their supplier - upon their request for an ETA - would ship third week of October.I just checked Summit's site a minute ago and it shows it available and will ship tomorrow. Hmmm...

zkx14 found it on Summit's own eBay shop, though. I've contacted them to see what they say.

I should probably edit my post - and the wanted thread - since I've ordered a kit from Auto Parts Canada Online | TheWrenchMonkey Canada but I want to wait until I get an actual confirmation that they've shipped.

Alright, Matt! Now I've finally been able to lay my mittens on a keg of molasses! 15 kilograms of the stuff. I'm going to sink the other LCA into that stuff right now (1:9 mix) and leave it until at least Sunday afternoon. If it needs more, I'll let it sit over next week.This is a process called Chelation. Its 1 part feed grade molasses to 9 parts water. Softer ferrous metals i have found it will eat. Stamped steel sheetmetal it wont eat. I lost a whole batch of sems fender screws and nuts because i wasnt paying attention. Luckily i found a wholesale supplier to replace these with new, however i still need to find the 5/16 wide washered nuts. It also eats off the crappy factory black dipped paint too

You need a plastic tub with a lid or large plastic trash can with lid depending on what you want to dip. You need enough solution to completely submerge the part. I found a rectangular 35 gallon trash can i plan on buying and using for wheels and my K frames.

Depending on the rust some parts clean up in a few days some in a little over a week. I had an oem mopar battery tray that took 8 days but was clean pitted steel when done. No brown corrosion spots. I tend to check on everything every few days. My sems body bolts i forgot about for 2 weeks, thats what killed them.

Once the parts are all cleaned of rust, you cannot let the air get to them or flash rust will occur. The trisodium phosphate powder mixed in solution with water in a pump type plant sprayer is what you need to use. 1/4 cup TSP to a gallon of water. Take 1 part at a time lift it from the molasses mixture and before the molasses water mixture dries on it you have to hose it off right away thoroughly with the water/tsp mix, then let air dry. I plan on making a drying rack with hooks to hang parts to air dry. The TSP in solution with the water allows rinsing of the molasses mixture and prevents flash rust. You can buy the tsp at lowes or home depot in the paint supplies section. A small box is about $3

Prep work for paint after it dries, well there is no prep work. As long as the part did not go into the solution greasy , and has residue still on it, just prime and paint. To be sure just wipe the parts down with a bit of laquer thinner and a clean cloth, or paper towel.

The molasses solution is non toxic, and can prob be used as plant or grass fertilizer when not needed anymore as it has a high iron content when it disolves rust.

(I'd recommend trying it on a spot first)

The bad part is the stink. This stuff stinks BAD!!!! Wear heavy duty rubber or chemical resistant gloves when working with it, as it absorbs into your skin then no matter how much you wash, your hands smell like it for days.

Anders you mentioned finding molasses, check a local agricultural feed store. A gallon cost me $10. For $20 more and a large trash can i will be dipping steel wheels and K frames LOL.

This'll be exciting! I'm wondering, how important is the TSP for post-process cleaning? What does it do, chemically?

moparmat2000

Well-Known Member

Alright, Matt! Now I've finally been able to lay my mittens on a keg of molasses! 15 kilograms of the stuff. I'm going to sink the other LCA into that stuff right now (1:9 mix) and leave it until at least Sunday afternoon. If it needs more, I'll let it sit over next week.

This'll be exciting! I'm wondering, how important is the TSP for post-process cleaning? What does it do, chemically?

It prevents flash rust on the bare metal. I scrub the part with a wire brush to make sure everything is clean before i remove it for good, then rinse with the TSP / water mixture (before) the molasses / water mixture dries, and the part wont flash rust. Let it air dry, or heat lamp it afterwards, primer, and paint it. I live in a somewhat dry environment so i actually have parts i pulled from the mixture , sprayed with the tsp, let dry on my workbench and have not primered with anything for months.

moparmat2000

Well-Known Member

Ok Anders, whats your verdict on the stinky assed molasses derusting solution? I was skeptical myself when i did this the first time. I await your results.

Good morning Matt!

I glanced at it this morning when I left for 'work' but I couldn't see much and the brake booster clamping ring looked unaffected. Didn't rinse it off, though.

Say, isn't there supposed to be any sort of sign of activity? Foam or bubbles? It all looks ... perfectly still.

Oh, and since I haven't got a sense of smell, it's hard for me to tell whether or not it stinks.

I glanced at it this morning when I left for 'work' but I couldn't see much and the brake booster clamping ring looked unaffected. Didn't rinse it off, though.

Say, isn't there supposed to be any sort of sign of activity? Foam or bubbles? It all looks ... perfectly still.

Oh, and since I haven't got a sense of smell, it's hard for me to tell whether or not it stinks.

moparmat2000

Well-Known Member

Did you use feed grade or whats called unrefined molasses.

It may take a few days to break down and ferment. Then you will see bubbles on top where its attacking the rust.

Its a good thing you dont have a sense of smell, this stuff stinks so bad, you cannot get the smell of it out of your nose for hours after working with it.

It may take a few days to break down and ferment. Then you will see bubbles on top where its attacking the rust.

Its a good thing you dont have a sense of smell, this stuff stinks so bad, you cannot get the smell of it out of your nose for hours after working with it.

It's used as animal feed from what I'm reading on the jug.

Here is a pic of what my vat looks like and what the parts look like now. It's definitely doing something but needs a few more days.

I didn't remember to take a before-pic of the LCA but it was pretty rusty.

View attachment 1714976422

Here is a pic of what my vat looks like and what the parts look like now. It's definitely doing something but needs a few more days.

I didn't remember to take a before-pic of the LCA but it was pretty rusty.

View attachment 1714976422

moparmat2000

Well-Known Member

Also sometimes the rust is hanging on after a week, and a quick rub with a brush and it comes right off as if you are rubbing dirt off.

I know there's some rust protection compound on that LCA where the mixture probably won't be able to get at the steel. But there is likely no rust under it anyway.

moparmat2000

Well-Known Member

Did you do your mix ratio 1 part molasses to 9 parts water? In the pic it looks a bit clear, or it may be that mine is pretty filthy by now.

BTW i did a bit more work on my fan shroud mould. I will post more pix and info later today.

BTW i did a bit more work on my fan shroud mould. I will post more pix and info later today.

Roughly 1:9, yes. It's standing outside and it's not very warm. I suppose the temperature is a parameter. It usually is in chemistry.

Google "DIY electrolytic rust removal" all you need is a battery charger water and bake baking soda at 400* before putting in the water! work like a camp and only in a few hours... part will look brand new..

Hi Madness!Google "DIY electrolytic rust removal" all you need is a battery charger water and bake baking soda at 400* before putting in the water! work like a camp and only in a few hours... part will look brand new..

Actually, I did some electrolytic rust removal a couple of pages back in the thread. It works great but has some drawbacks. Mainly, it is primarily 'line of sight' which means it doesn't work great on intricate parts such as an LCA. It is a good tip, though, no doubt about that!

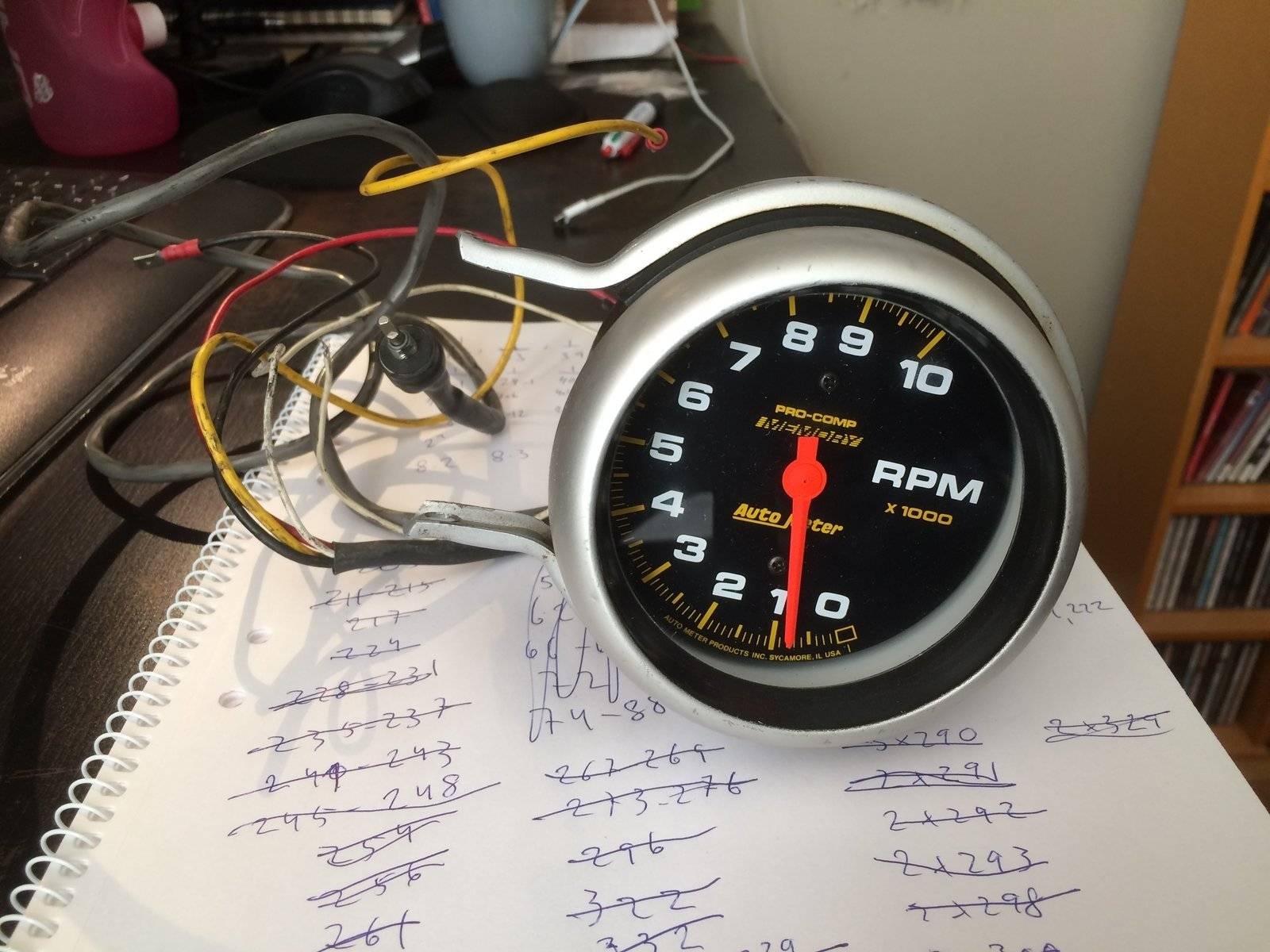

Well look what I got!

It's a Pro-Comp 6602 designed to work with Vertex AOC magnetos. Now, I don't have a magneto on my car but I figure it really couldn't be all that hard to adapt the signal.

It was a bargain at $65 or so (list price in the US roughly $310 but it isn't sold any longer) so I just had to have it.

Does anyone have specific knowledge of what the input on one of these tachs looks like, electrically?

Before you start googling, I've done a lot of that already.

It's a Pro-Comp 6602 designed to work with Vertex AOC magnetos. Now, I don't have a magneto on my car but I figure it really couldn't be all that hard to adapt the signal.

It was a bargain at $65 or so (list price in the US roughly $310 but it isn't sold any longer) so I just had to have it.

Does anyone have specific knowledge of what the input on one of these tachs looks like, electrically?

Before you start googling, I've done a lot of that already.

Sooo ... I pulled my crap out of the molasses vat today. That makes total exposure two weeks. The results are a little confusing. On most of the items I notice no improvement at all but on the LCA, it seems all rust is gone where there isn't still rust protectant shielding the steel.

I can think of only three possible reasons. 1: it's been too cold. 2: the mixture was somehow wrong. 3: Wrong kind of molasses.

I'm inclined to think there is something that is supposed to happen, you mentioned fermenting, @moparmat2000. I really don't think much has happened at all in that sense. Not having a sense of smell doesn't help here.

I think I'll give it another go, this time indoors as the weather is getting colder every day. We've been scraping the windshield a couple of mornings already.

Anyway, here are pictures of the carnage. Nowhere near you results, Matt, as you can see.

I can think of only three possible reasons. 1: it's been too cold. 2: the mixture was somehow wrong. 3: Wrong kind of molasses.

I'm inclined to think there is something that is supposed to happen, you mentioned fermenting, @moparmat2000. I really don't think much has happened at all in that sense. Not having a sense of smell doesn't help here.

I think I'll give it another go, this time indoors as the weather is getting colder every day. We've been scraping the windshield a couple of mornings already.

Anyway, here are pictures of the carnage. Nowhere near you results, Matt, as you can see.

moparmat2000

Well-Known Member

Not sure anders. The stuff i used was animal molasses. Or whats called raw unrefined molasses. They use it to get cattle to eat the food the ranchers put out for em, or to bait for deer or wild hogs. You would never use this to bake or anything like that.

Cold weather could retard the process too. All i know is that stuff would be clean after a week in my tank.

Cold weather could retard the process too. All i know is that stuff would be clean after a week in my tank.

Last edited:

I'm pretty confident I have 'feed grade' molasses. Like I said, I'll try it again, be a little more careful when diluting it, maybe go 1:8 in stead, and keep it a little warmer.Not sure anders. The stuff i used was animal molasses. Or whats called raw unrefined molasses. They use it to get cattle to eat the food the ranchers put out for em, or to bait for deer or wild hogs. You would never use this to bake or anything like that.

Cold weather could retard the process too. All i know is that stuff would be clean after a week in my tank.

Just to be clear: I am in no way questioning you or your results, Matt, I just want to know what I'm doing wrong.

-

Similar threads

- Replies

- 9

- Views

- 351

- Replies

- 10

- Views

- 585

- Replies

- 142

- Views

- 8K