dusterbd13

Well-Known Member

so, a little bit has happened since the last update.

ive put about 400 miles on the car.

weve done a family trip

my wife gave her input.

the family trip went great. we went to the NC transportation museum in Spencer, NC. spent the day looking at the exhibits, riding the train, and enjoying our time as a family. as luck would hav it, the plymouth club was having a car show there that weekend, so we put the duster in it. didnt win anything, but that wasnt the point. we had a blast.

we also learned a few things about the car, and traveling as a family in it.

1. mary has no leg room in the back seat. with her car seat, her legs are firm up against the seat back on the pass side.

2. theres a lot of noise from the trunk.

3. the turn signals dont work

4. the heater never gets completely closed off.

5. my wife feels uncomfortable with only a lapbelt, and cant wear the fixed shoulder belt because it hits her in the ear.

6. with a full tank of gas, stroller and assorted stuff, and the family, the right rear tire comes into contct with the fender lip

we also had the shifter come apart. the bolts that hold the stick to the box loosened, and one fell out. when i put it back together at home, i cleaned, adjusted, greased, and locktited everything.

all in all, a great outing. i wouldnt trade it for the world.

so ive started working on that list some. as well as my other priorities.

the first one to start on was the trunk, mostly because it annoyed me and i had most of the stuff to do what i wanted to do.

i pulled everything out, cleaned all the metal, and started to sound deaden it. my wife came down to the shop for something, and made the comment about the battery being in a very inconvienient spot for fitting luggage in the trunk. that was all the encouragement i needed. i had been debating moving it over the axle centerline for a little better weight distribution, but couldnt justify it. well, we all know what comes next. the snowball effect.

thankfully, i have plenty of supplies stashed away. like battery cable, wiring, etc. moving the battery to the center of the package tray area allowed me to upgrade my amp wiring, upgrade my MSD power and ground wiring, and free up a lot of trunk space. unfortunately, it also made my current subwoofer enclosure unusable. so im thinking about that, and have something to try before i make a decision.

to lay down the sound deadening, i had a few sheets of the mcmaster carr adhesice backed elastomeric left over from when i did my mazda. so i used it.

heres what the current product looks like:

used a heat gun and a j-roller to get it to fit well.

i also decided while i was in there to finally get a spare tire and jack for the first time since 1998. while i was at beavers honda salvage up in moorseville picking up an engine, i spotted a jack, wrench, and carrier assembly from an 07 civic coupe. had the right measurements according to the tape measure, so i bought it for 35. fits right in, but my spare doesnt. the 235/60/15 i have doesnt fit the wheelwell, and the 255/40/17 sticks up a rediculous amount. so im going to find a donut spare from a 1998 mustang cobra.

heres what im talking about:

theres only about 6 inches from the top of the assmbly to the trunk lid.

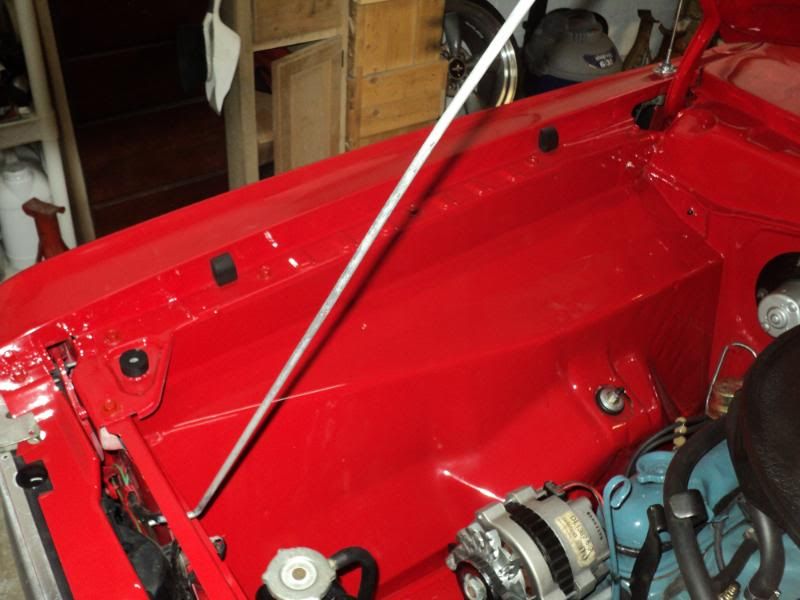

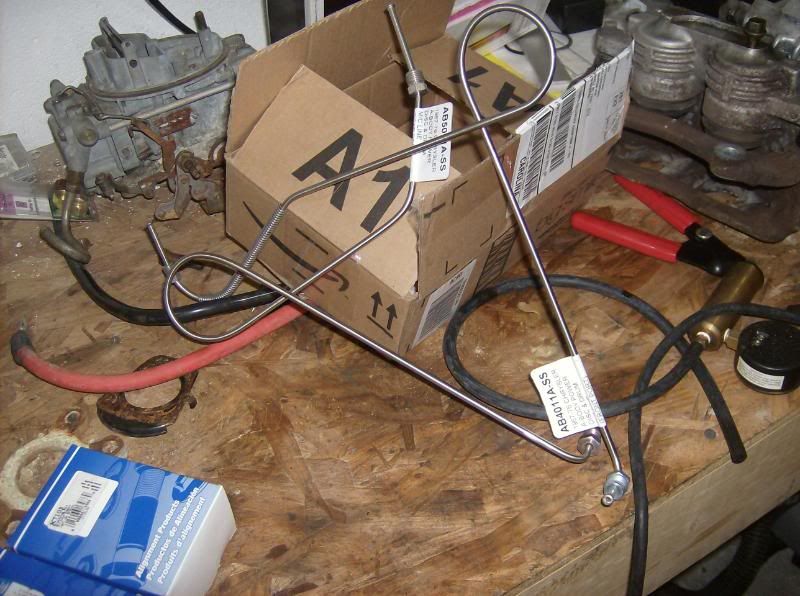

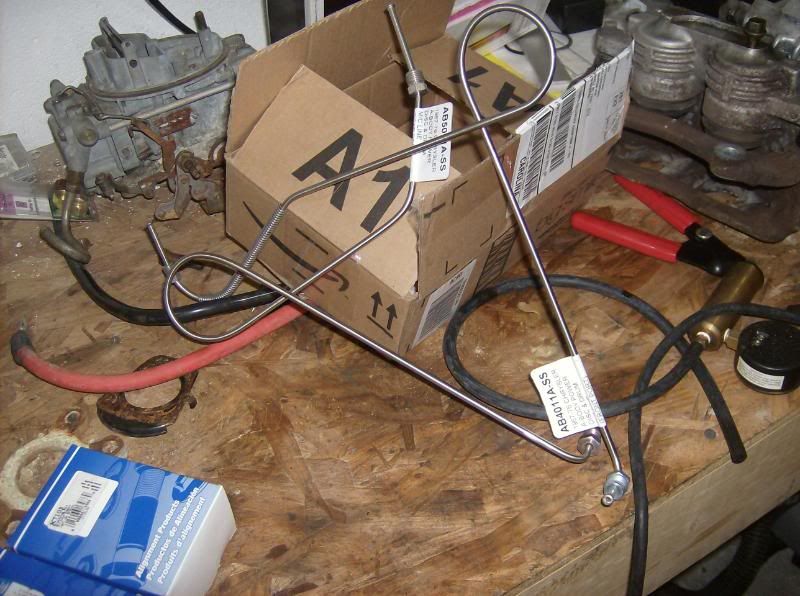

also, ive been working on my power brake cnversion. ive got my stainless lines (40)

and verified that my junkyard booster was good. (35)

im in the process of cleaning up the booster. the master was a 4 wheel drum master, so im going to toss it on the shelf and keep it for if i ever go 4 wheel disc. for the conversion, im going to retain my 1 inch bore manual master. according to my FSM from 1970, manual and power used the same bore master cyl, so i see no reason to change it. an its already paid for!

also, i ordered my new UCA bushings, moog K7103. got them for 52.74 from amazon.com. cheapest o could find them.

after i get the brakes sorted out, ill get those put in.

so budget total is 1027.86

next stop is going to be getting the booster in, and finish my trunk.

michael

ive put about 400 miles on the car.

weve done a family trip

my wife gave her input.

the family trip went great. we went to the NC transportation museum in Spencer, NC. spent the day looking at the exhibits, riding the train, and enjoying our time as a family. as luck would hav it, the plymouth club was having a car show there that weekend, so we put the duster in it. didnt win anything, but that wasnt the point. we had a blast.

we also learned a few things about the car, and traveling as a family in it.

1. mary has no leg room in the back seat. with her car seat, her legs are firm up against the seat back on the pass side.

2. theres a lot of noise from the trunk.

3. the turn signals dont work

4. the heater never gets completely closed off.

5. my wife feels uncomfortable with only a lapbelt, and cant wear the fixed shoulder belt because it hits her in the ear.

6. with a full tank of gas, stroller and assorted stuff, and the family, the right rear tire comes into contct with the fender lip

we also had the shifter come apart. the bolts that hold the stick to the box loosened, and one fell out. when i put it back together at home, i cleaned, adjusted, greased, and locktited everything.

all in all, a great outing. i wouldnt trade it for the world.

so ive started working on that list some. as well as my other priorities.

the first one to start on was the trunk, mostly because it annoyed me and i had most of the stuff to do what i wanted to do.

i pulled everything out, cleaned all the metal, and started to sound deaden it. my wife came down to the shop for something, and made the comment about the battery being in a very inconvienient spot for fitting luggage in the trunk. that was all the encouragement i needed. i had been debating moving it over the axle centerline for a little better weight distribution, but couldnt justify it. well, we all know what comes next. the snowball effect.

thankfully, i have plenty of supplies stashed away. like battery cable, wiring, etc. moving the battery to the center of the package tray area allowed me to upgrade my amp wiring, upgrade my MSD power and ground wiring, and free up a lot of trunk space. unfortunately, it also made my current subwoofer enclosure unusable. so im thinking about that, and have something to try before i make a decision.

to lay down the sound deadening, i had a few sheets of the mcmaster carr adhesice backed elastomeric left over from when i did my mazda. so i used it.

heres what the current product looks like:

used a heat gun and a j-roller to get it to fit well.

i also decided while i was in there to finally get a spare tire and jack for the first time since 1998. while i was at beavers honda salvage up in moorseville picking up an engine, i spotted a jack, wrench, and carrier assembly from an 07 civic coupe. had the right measurements according to the tape measure, so i bought it for 35. fits right in, but my spare doesnt. the 235/60/15 i have doesnt fit the wheelwell, and the 255/40/17 sticks up a rediculous amount. so im going to find a donut spare from a 1998 mustang cobra.

heres what im talking about:

theres only about 6 inches from the top of the assmbly to the trunk lid.

also, ive been working on my power brake cnversion. ive got my stainless lines (40)

and verified that my junkyard booster was good. (35)

im in the process of cleaning up the booster. the master was a 4 wheel drum master, so im going to toss it on the shelf and keep it for if i ever go 4 wheel disc. for the conversion, im going to retain my 1 inch bore manual master. according to my FSM from 1970, manual and power used the same bore master cyl, so i see no reason to change it. an its already paid for!

also, i ordered my new UCA bushings, moog K7103. got them for 52.74 from amazon.com. cheapest o could find them.

after i get the brakes sorted out, ill get those put in.

so budget total is 1027.86

next stop is going to be getting the booster in, and finish my trunk.

michael