so I've spent a little time over the last week working on the duster.

first order of business was getting the seats fit and wired into the car. decided that id start with the drivers side, as that's the most important for comfort and fit. (makes sense, as I'm the ONLY person that drives this thing.)

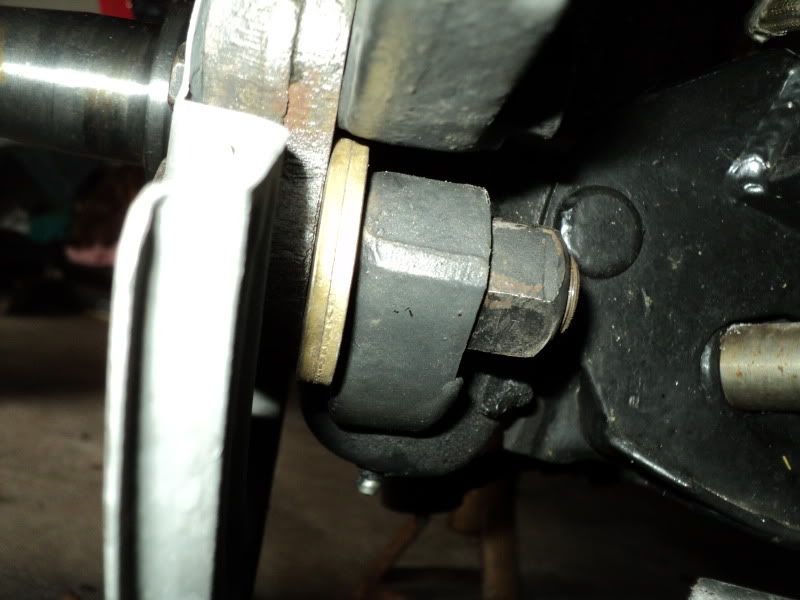

when i started out, the seat was awfully high in the front, causing some discomfort between me, the roof, the steering wheel, and the clutch pedal. i had it lowered as much as i could. heres what the stock Lincoln mount looked like:

i used the back mounting hole for the bench seat to base things off of. put a spare carriage bolt through the back outboard Lincoln mount point and the factory hole. that's how the seat was sitting in that picture.

wound up figuring out that the front leg of the seat was not sitting flush to the contours of the floor pan, and that if i trimmed it a bit, it would allow the front edge of the seat to drop dramatically, alleviating most of the fitment problems.

so i got out the harbor freight sawzall that my old boss gave me for Christmas one year (my good craftsman was broken by my brother, and i haven't fixed it yet) and started a cuttin'.

heres what i wound up with.

now i have a lot more clearance at all the tight spots. just about perfect seat bottom angle as well, and that's with the tracks all the way bottomed out in their travel.

this is when i started to over think things and screwed up.

when doing this, never try to use a tape measure and estimate the center line of the car. wound up moving the whole seat 1.5 inches towards the door, and mounting it there. seemed good in the garage, so i took it up the road for a test. it just didn't sit right. was offset to the steering wheel, which made my hips twist on the pedals, etc. went back to the shop, and tried the bench mounting point again. only put the one bolt in it, as i already had a couple of spare holes in the floor pan now.

went back up the road, and it fit me like a glove. so, i figure the few holes now count as weight reduction.

i took the car down to troy, up through the uwharries, and back home. before i even got the rest of the install completed, i knew it was the best money and time I've spent on the car in a long time. i also knew that i had a few new problems to contend with.

problem 1. when i was adjusting the seat, i heard something sound like it was cracking, and my front component speakers stopped working. apparently the seat motors and the amp were attempting to occupy the same space at the same time now, and the seat won. dammit.....

problem 2. i have no cup holder. for the last 16 years, I've been putting my coffee cup in between my side and the armrest on the bench. fit great and NEVER spilled.

problem 3. i lost my armrest

all solvable.

first though, i had to finish installing the seats.

drilled the new front mounting hole for the door side, and moved on to the inside. the tracks on that side needed to come up a hair in the back, and a bunch in the front. for the back, i used a steel wheel lug nut from an 86 dodge diplomat as a spacer. the tapered side fit perfect in the ford mounting hole, and it leveled the seat out to .1 degree at the back. to get the front the same, i wound up using 1/8 wall 1X1 square tubing to make a spacer. length of 1.75 inches.

also, made some floor washers/seat reinforcements out of some 1/4 plate i had laying around. 3X3 squares with a hole drilled in them. also, for hardware, i used some carriage bolts i had bought down at Lowe's with nylock nuts. total in hardware was 5.86

to power the seats, i had left a 20 amp lead in my harness along the door sills for eventual power windows or locks. so i pulled those over to where the seats were to power the seats.

to fix my amp problem, i wired the components directly to the head unit. they actually sound better now that they're not powered by the old audiovox amp.

also learned that after powering the passengers side seat, it has a micro-switch in it. when you tilt the seat back forward for rear seat access, it automatically slides the seat forward with the electric adjusters. when you put it back upright, it goes back to exactly where it was set before. really nice unexpected feature. thanks ford!

heres pics of both seats mounted, and the mounts i made. (both seats mounted the same way, with the same hardware and measurements)

after i got done with the seats, i went back to the trunk. i permanently mounted the amp and subwoofer enclosure, as i dint want them sliding around at high rates of lateral acceleration. use #10 screws and fender washers up through the trunk floor to mount the sub box, and some s10 screws with captured washers to mount the amp. all these parts came out of my magic bolt box.

last on the list is my news of the week:

I'm going autocrossing with this car and my dad on Sunday. Tarheel Sports Car Club is having their test and tune day down at Maxton, and its time to see what this old girl can really do. I'm excited. hopefully ill have some time to get the carb fine tuned between now and then.

total is 1717.64

stay tuned, ill have action shots good lord willing.

michael