You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A couple reasons why I hate doing port work after others

- Thread starter pittsburghracer

- Start date

-

Well I started tubing the second head today and this must have been the second head the guy ported as he stopped short of having to tube the heads. The pinch varies from .990-1.025 so now I can just do my thing and tube them instead of replacing his tubes. My son Matt is bringing the valves this weekend when he comes to visit over Christmas. Pretty sure he’s bring new Pac springs and retainers too. Vic has lots of connections in the racing community so I guess we are going to be trying a smaller diameter, lighter weight spring. Not sure how much visiting and bs’ing Matt and I will be doing on his week home but I may have some flow numbers next week from the first head. This head should be ported and ready for a valve job too. I’m finding out if I come down to the shop more often I can actually turn out some work. I may end up with time this winter to finish my set of heads and get my hands dirty on my 8 sets of LS heads sitting here. Ohhhh he went through the exhaust port into the header bolt holes again. I may try to mark them and try to talk Vic into running studs in at least those holes.

When you are tubing the pushrod holes, are you porting first and then tubing? Or the other way round?

I always tube first so I can port over till I just touch the tubing.When you are tubing the pushrod holes, are you porting first and then tubing? Or the other way round?

What size cross section you getting with tubing ?I always tube first so I can port over till I just touch the tubing.

I was also wondering, I was watching a Eric Weingartner video and he said he finds peak flow and the short side csa generally correlate Eg. 300 cfm and 3.0" short side area do you notice a similar correlation?

Dartswinger70

Well-Known Member

I got out of the wrench business years ago mainly due to customers. Near the end of my 20 year career ( I was out by my early 40s) I used to say "There isnt anything that constitutes an an emergency unless my car doesnt start when I go to leave here at 5 o clock..."I am Done working on other people's stuff!!

If they bring it to my shop, I will fix it for free if I can do

it in less than an hour for no charge given they leave

it for a few days until I can find the time.

Beyond that, I will give them my opinion, but I will not

put my hands on it! If they argue with me about my

advise (common) that will be the last time they receive

any from me.

At 75 year old, I have come to the realization that I have more

money than I have time at this point. I have lost patience with

time wasters and folks that grind me to death on the price of something!

And then they are late or don't show up.I got out of the wrench business years ago mainly due to customers. Near the end of my 20 year career ( I was out by my early 40s) I used to say "There isnt anything that constitutes an an emergency unless my car doesnt start when I go to leave here at 5 o clock..."Oh yeah they loved tryin to get you to stay late for "emergencies"

What size cross section you getting with tubing ?

I was also wondering, I was watching a Eric Weingartner video and he said he finds peak flow and the short side csa generally correlate Eg. 300 cfm and 3.0" short side area do you notice a similar correlation?

I listed a bunch of measurements in the speedmaster sticky posts. About the only measurement I take now is bottom

Of the intake port to roof and i

Take calipers and measure the thickness of the short turn. Those number I don’t give out and are only time savers for me to do final short turn shaping.

Ah! So you've seen some of my work, huh?Hey it's better than the old school grind till you break through then JB weld mess.

I'm "only" 59, but starting to come to this exact same realization.At 75 year old, I have come to the realization that I have more

money than I have time at this point. I have lost patience with

time wasters and folks that grind me to death on the price of something!

PRH

Well-Known Member

Ohhhh he went through the exhaust port into the header bolt holes again.

Same port/position as the other head?

Dartswinger70

Well-Known Member

Oh yes and they say "But I need a car..." and we'd hand them the phone number to the car rental guy...And then they are late or don't show up.

Well Matt finally got me the Cometic gasket size Vic’s running and it’s 4.040 bore size so my hands are really tied on how much chamber work I can do.

-Boosted-

Hard Member

Same size bore I run with my .030 pistons.Well Matt finally got me the Cometic gasket size Vic’s running and it’s 4.040 bore size so my hands are really tied on how much chamber work I can do.

Same size bore I run with my .030 pistons.

I’m running a 4.060 Cometic right now on my 4.030 bore. I did these heads back around 2008 and I’m almost positive I worked the chamber to a 1008 felpro (4.180) and I’ve never had an issue. But I think there’s performance to be gained if I go with a bigger head gasket than a 4.060

-Boosted-

Hard Member

Can't wait for the tracks to reopen so I can start tuning down to the nitty gritty.... lolI’m running a 4.060 Cometic right now on my 4.030 bore. I did these heads back around 2008 and I’m almost positive I worked the chamber to a 1008 felpro (4.180) and I’ve never had an issue. But I think there’s performance to be gained if I go with a bigger head gasket than a 4.060

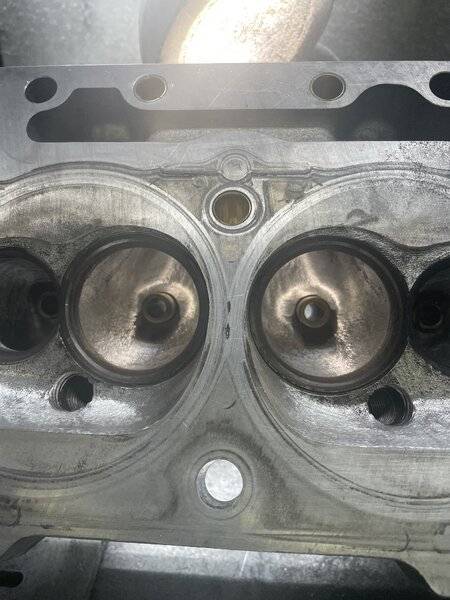

Another very productive day. Man it feels good to feel 29 again.

-Boosted-

Hard Member

Hell yeah! Looks great my friend!

mygasser

Well-Known Member

this 29 year old you're feeling sure seems to cheer you up

Hell yeah! Looks great my friend!

If I didn’t know better I would be paranoid and think that @-Boosted- is trying to get on my winter porting list just in case those TrickFlow heads don’t do the TRICK. I received another care package today with a very nice hoodie and probably the nicest hat I’ve ever owned. Thank you very much Bill.

-Boosted-

Hard Member

Merry Christmas my friend!If I didn’t know better I would be paranoid and think that @-Boosted- is trying to get on my winter porting list just in case those TrickFlow heads don’t do the TRICK. I received another care package today with a very nice hoodie and probably the nicest hat I’ve ever owned. Thank you very much Bill.

View attachment 1716181483

View attachment 1716181484

View attachment 1716181485

Nice thread apart from the strange ramblings in the middle?

I always port for myself and (maybe) sell the heads as 'done' (sometimes).

Most folks don't know diddly squat about the time and effort that goes into them!

So you are lucky to get any 'recompense' from wannabe drag racers at ALL.

A craftsman loves to craft and it don't matter if you is 29 or 69.

Flow-benches are a magical thing but a good porter knows what's right and wrong!

'Flow' high in the port is more important than low down.

Air like water, likes a straight line, any protrusions are a eddy point.

So I like to cut back the top of the port to within an ant's leg of break through.

Feel free to say ''I'm talking crap'', as most folks do...

Is this a small bulge or just a light shadow (blue arrow)?

ps How many heads do you need to port to call yourself a PROPER PORTER?

I always port for myself and (maybe) sell the heads as 'done' (sometimes).

Most folks don't know diddly squat about the time and effort that goes into them!

So you are lucky to get any 'recompense' from wannabe drag racers at ALL.

A craftsman loves to craft and it don't matter if you is 29 or 69.

Flow-benches are a magical thing but a good porter knows what's right and wrong!

'Flow' high in the port is more important than low down.

Air like water, likes a straight line, any protrusions are a eddy point.

So I like to cut back the top of the port to within an ant's leg of break through.

Feel free to say ''I'm talking crap'', as most folks do...

Is this a small bulge or just a light shadow (blue arrow)?

ps How many heads do you need to port to call yourself a PROPER PORTER?

Dale Davies

Well-Known Member

Sometimes better to tell a potential customer you do not want to do the job or that you are too busy. Better to write off the 1/2 hour to inspect up front, than try repairing a more or less losing situation.Trying to correct someones screw up usually takes twice to three times longer, rather than them bringing it to me first. I try to be fair with fellow enthusiasts, but sometimes they really try my patience and I've lost a few due to labor costs.

Nice thread apart from the strange ramblings in the middle?

I always port for myself and (maybe) sell the heads as 'done' (sometimes).

Most folks don't know diddly squat about the time and effort that goes into them!

So you are lucky to get any 'recompense' from wannabe drag racers at ALL.

A craftsman loves to craft and it don't matter if you is 29 or 69.

Flow-benches are a magical thing but a good porter knows what's right and wrong!

'Flow' high in the port is more important than low down.

Air like water, likes a straight line, any protrusions are a eddy point.

So I like to cut back the top of the port to within an ant's leg of break through.

Feel free to say ''I'm talking crap'', as most folks do...

Is this a small bulge or just a light shadow (blue arrow)?

ps How many heads do you need to port to call yourself a PROPER PORTER?

View attachment 1716181996

Ya like I said these ports are not finished. I love these rotating stands but after the valve job and after they are off my rotating stands I stand the heads upright to straighten my side walls. That way I’m finish grinding the walls horizontally and not vertically. Every part of these ports are finished and measured at that time them Off to my flowbench. During the finishing process I use two sometime three different chairs to get the right height to visually see each port at different angles.

-

Similar threads

- Replies

- 6

- Views

- 688

- Replies

- 18

- Views

- 1K

- Locked

- Replies

- 4

- Views

- 966

- Replies

- 41

- Views

- 3K

- Replies

- 30

- Views

- 2K