Link to my prior post

http://www.forabodiesonly.com/mopar/showthread.php?t=176755&highlight=Modernized

Since then, I found a maybe better part (MBRP400100CT, photo below), to use on my Valiant. Bigger than I expected. I will cut in two and bolt together flipped for a forward drop either charging or discharging the battery.

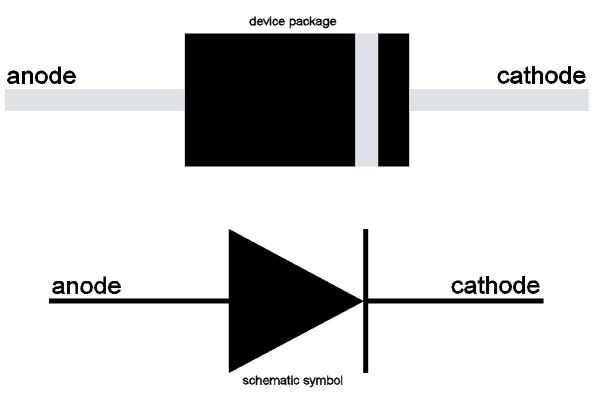

Re design, cudajim is correct that common silicon diodes have a nominal 0.7 V forward drop. Both diodes I used are Schottky types (less drop). Anyway, it is actually a curve that depends on current flow. Max is 0.7 V (@ 200 A) and dV decreases with temperature so kind of fail-safe. This matches what I measured I need. Read the post for more details. For some reason, the theory of i, dV, and R ticked off one reader. To specifically answer 4woody, the 2nd diode should give a 0.4 V min drop, so all alternator current should flow thru the ammeter at low currents (~1/3 scale). As alternator output increases, dV across your ammeter increases to ~0.7 V at full factory scale (~40 A), but you will never peg out because current will start flowing thru the diode bypass path. You would have to exceed 200 A to peg your ammeter. Show me that alternator.

Re installation. The diode pair is a new path from the alternator output stud to BATT+. Leave the existing wiring to your ammeter in place also. In my Dart, I ran across the SB timing cover, using a cable from a Magnum engine (as factory). Haven't decided the path in my slant. Most people could run a 6 awg wire to the starter relay big stud (BATT+). Either end is a suitable heat sink to bolt the diodes to (70 W max heat).I will use a modern relay box, as in my Dart.

Much mis-information on how your ammeter works. It is the only path to BATT+ from the dash, so all current flow into or out of the battery goes thru the ammeter. Under-hood loads like the starter, horn, and starter relay don't pass thru the ammeter, but they are transient loads so no need to meter. If your alternator is supplying all loads, you won't see any draw from the battery ("discharge" on ammeter).

I could sell these, but $13 for the diode pair, more for 6 awg cable, connectors, shipping, so probably $30 before any profit. Add in my labor, and little profit plus the grief/risk in dealing with angry, unskilled buyers. I would have to charge $100, and who would pay? For now, I give you the knowledge to make your own. That is much simpler than buggering with your ammeter in my opinion. Of course, also fix your bulkhead connector (as 67Dart273 laments) or you will smoke things even with the diode protection. Though, if you have a 65 like me, your bulkhead has the (apparently) 1-year only power feed-thrus (photo in prior post), so no melted bulkhead.