So put the motor together today and got to the valve train part. When I bought this it had bad lifters and a wiped cam and bent pushrods. I repurchased the same parts assuming PO did not adjust rockers properly. Well I'm using edelbrock 6077 heads. with edelbrock 7177 cam. The heads say to use stock length 7.375. I know measuring these cup/ball can be difficult. My new pushrods measure 7.5 end to end. They are melling mpr-155. When I look those up they say they are actually 7.342 shorter than what heads recommend. But when I was trying to set my rockers...the cups hit the rocker. These are stock stamped rockers. Everything just seems like my push rods are too long. This is a pretty complicated topic for us noobs. Looked at many other threads but not sure. Help please. :???::???:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another pushrod length question.

- Thread starter 71dart318

- Start date

-

nm9stheham

Well-Known Member

Edelbrock 60779 heads? There is not such thing as a 6077 Edelbrock head.....

Stock stamped LA small block rockers use ball-ball pushrods, not ball-cup pushrods......something is confused here. Please clear up waht rockers you are using; if stock stamped rockers, then you need ball-ball pushrods. If the pushrod end of the rocker has a ball on it that fits into a cup on the pushrod, it sounds like you have 273 adjustable rockers....??? Can you share a pix of a rocker?

BTW, the cups are typically .130-.180 deep from top edge to bottom. Ball-cup measurements from the tip of the ball to the bottom of the cup ( the so-called 'effective length') will be that much shorter than the measurement from end of ball to top edge of cup. So you need to know what measurement is being spec'd.

BTW on page 2 of the instructions it clearly says you need to use adjustable rockers for cams with lift higher than stock.

ROCKER ARMS AND VALVE TRAIN: Adjustable rocker arms must be used with cams having greater than stock valve lift. We recommend original equipment or aftermarket adjustable rocker arm assemblies, along with matching pushrods (stock length, 7.375").

Stock stamped LA small block rockers use ball-ball pushrods, not ball-cup pushrods......something is confused here. Please clear up waht rockers you are using; if stock stamped rockers, then you need ball-ball pushrods. If the pushrod end of the rocker has a ball on it that fits into a cup on the pushrod, it sounds like you have 273 adjustable rockers....??? Can you share a pix of a rocker?

BTW, the cups are typically .130-.180 deep from top edge to bottom. Ball-cup measurements from the tip of the ball to the bottom of the cup ( the so-called 'effective length') will be that much shorter than the measurement from end of ball to top edge of cup. So you need to know what measurement is being spec'd.

BTW on page 2 of the instructions it clearly says you need to use adjustable rockers for cams with lift higher than stock.

ROCKER ARMS AND VALVE TRAIN: Adjustable rocker arms must be used with cams having greater than stock valve lift. We recommend original equipment or aftermarket adjustable rocker arm assemblies, along with matching pushrods (stock length, 7.375").

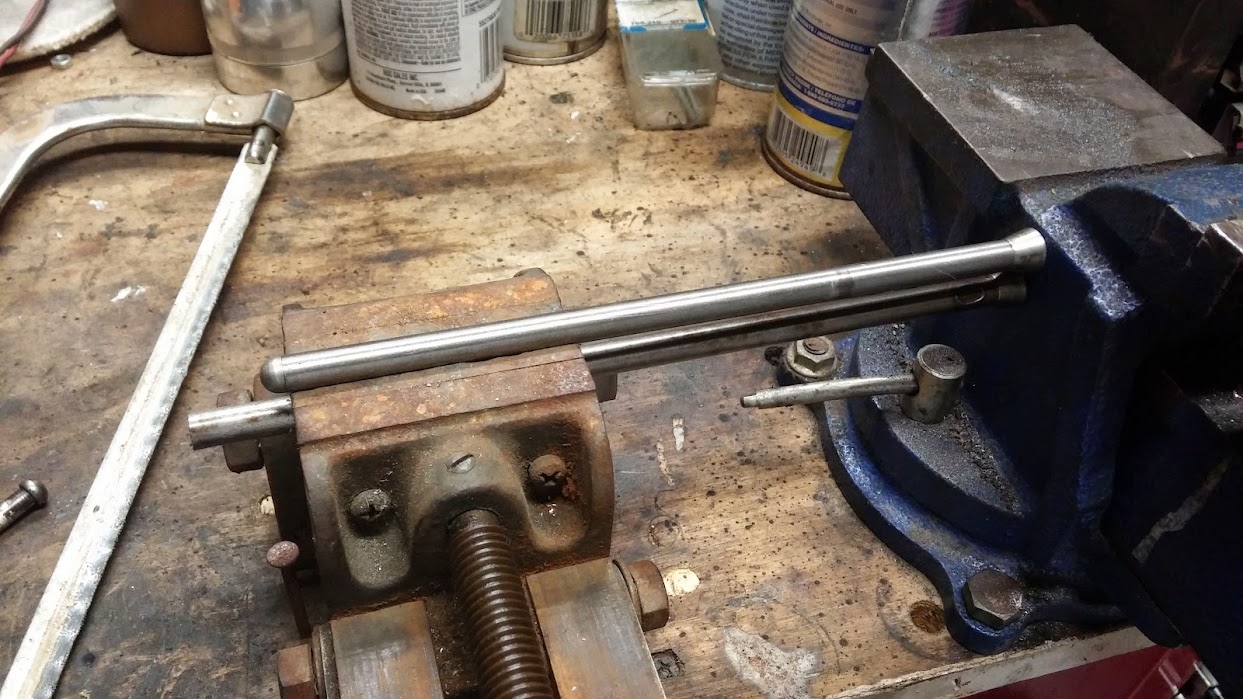

They are adjustable style and your right on 60779. it had cup/ball and got the number off them and ordered all new ones. but think this might have been part of the problem pervious. When I started to set them, when trying to get zero clearance in step one...then 1/4 turn four final adjustment the cup is still on the rocker. Would still take several turns to clear. So I stopped and decided to look into this issue. And still don't know what I need.

Attachments

Marcohotrod

Well-Known Member

you need shorter pushrods. the mpr 155 is stock replacement for 273 with shorter solid lifters. edelbrock with 7.375" is maybe measuring from ball to end of cup. u want comp cams 7821-16 at 7.234" ball to bottom of cup with your hydraulic lifters

nm9stheham

Well-Known Member

OK, those are the 273 adjustable rockers.... that is good. They are not stamped rockers.

The best way to deal with this is as follows:

1. Order a pair of checking pushrods. These are adjustable for length for set-up purposes. Get a set that covers the 6.5-7.5" range or thereabouts. Get some thin ones; fat ones will have problems in the smaller pushrod holes in the Edelbrocks. Comp 7709-1 ought to work but double-check my PN here.

2. Remove all the pushrods. Put the engine at TDC with cylinder #1 at the firing position; i.e., both lifters fully down. #6 lifters will be slightly raised in their bores. Place the 2 checking pushrods on the #1 lifters, and adjust them short.

3. Install the rocker assembly on the #1 side and torque down. Set the adjusters on the rockers where you think they should be when adjusted. A couple of turns exposed on the underside of the rocker seems about right to me, but make your own judgement.

4. Now adjust the checking pushrods so that they juuust barely take up the slack. The idea is to take up the slack, but not to push the lifter pistons down into the lifter bodies.

5. Remove the checking pushrods and measure them carefully. You need to find a way to measure from the ball end to the bottom of the cup. I measure the depth of the cup carefully, and then subtract it from the overall length. This gives you 'effective' length of a ball-cup pushrod.

6. Once you have the length of the checking pushrods, add the lifter preload that you want. A number of .040-.060" is common.

7. Order to this number and be happy. Make sure the ends are 5/16". The final rocker adjuster adjustment will be about a turn further in than with the checking setup, to give the lifter preload.

8. Some folks will measure at all 4 corners (#1, 2, 7 & 8) and average them.

FWIW, our pushrods ended up being 7.050" effective length with the same heads and PRW AL rockers. But those rockers are a bit different than yours so don't use that number except as a reference.

(BTW, I corrected the range length of the cup depth I posted above.)

The best way to deal with this is as follows:

1. Order a pair of checking pushrods. These are adjustable for length for set-up purposes. Get a set that covers the 6.5-7.5" range or thereabouts. Get some thin ones; fat ones will have problems in the smaller pushrod holes in the Edelbrocks. Comp 7709-1 ought to work but double-check my PN here.

2. Remove all the pushrods. Put the engine at TDC with cylinder #1 at the firing position; i.e., both lifters fully down. #6 lifters will be slightly raised in their bores. Place the 2 checking pushrods on the #1 lifters, and adjust them short.

3. Install the rocker assembly on the #1 side and torque down. Set the adjusters on the rockers where you think they should be when adjusted. A couple of turns exposed on the underside of the rocker seems about right to me, but make your own judgement.

4. Now adjust the checking pushrods so that they juuust barely take up the slack. The idea is to take up the slack, but not to push the lifter pistons down into the lifter bodies.

5. Remove the checking pushrods and measure them carefully. You need to find a way to measure from the ball end to the bottom of the cup. I measure the depth of the cup carefully, and then subtract it from the overall length. This gives you 'effective' length of a ball-cup pushrod.

6. Once you have the length of the checking pushrods, add the lifter preload that you want. A number of .040-.060" is common.

7. Order to this number and be happy. Make sure the ends are 5/16". The final rocker adjuster adjustment will be about a turn further in than with the checking setup, to give the lifter preload.

8. Some folks will measure at all 4 corners (#1, 2, 7 & 8) and average them.

FWIW, our pushrods ended up being 7.050" effective length with the same heads and PRW AL rockers. But those rockers are a bit different than yours so don't use that number except as a reference.

(BTW, I corrected the range length of the cup depth I posted above.)

I agree with Marcohotrod. From looking at your picture you need shorter pushrods. When all adjustments are finished you should have 1 or 2 threads showing on the bottom side of the rocker arms.

nm9stheham beat me to it. I agree with him also.

nm9stheham beat me to it. I agree with him also.

pishta

I know I'm right....

You got 3 options:

1. Shim up the shafts to get more distance between the rocker and the lifter, not the best.

2. Get shorter pushrods, best but you still have to measure and order.

3. Pull tips out of your new pushrods, cut to length and press tips back in. They are not that hard to shorten and the tips dont need to be welded, just an interference fit.

1. Shim up the shafts to get more distance between the rocker and the lifter, not the best.

2. Get shorter pushrods, best but you still have to measure and order.

3. Pull tips out of your new pushrods, cut to length and press tips back in. They are not that hard to shorten and the tips dont need to be welded, just an interference fit.

nm9stheham

Well-Known Member

^^^ Now that's a workbench with character!! (And unlike mine, you can actually see the main surface LOL)

nm9stheham

Well-Known Member

For the ones I recall, the tip is inserted and crimp welded in place.

Your can also get kits from Comp or get them made at Smith Borthers in Oregon. Here is our article on build some: http://www.forabodiesonly.com/mopar/showthread.php?t=330026

Your can also get kits from Comp or get them made at Smith Borthers in Oregon. Here is our article on build some: http://www.forabodiesonly.com/mopar/showthread.php?t=330026

Marcohotrod

Well-Known Member

I say again 7.23" ball to bottom of cup gives .030" preload, U have adjustable rockers, probably do not need custom pushrods

nm9stheham

Well-Known Member

Is that with the Edelbrock heads?I say again 7.23" ball to bottom of cup gives .030" preload, U have adjustable rockers, probably do not need custom pushrods

-

Similar threads

- Replies

- 7

- Views

- 11K

- Replies

- 8

- Views

- 212