You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Biohazard

- Thread starter Teeth & Tires

- Start date

-

Nice work Dan!!!!!

Thanks, man! I'm happy with the outcome. Sure, it's not what it could be properly chromed and all that but where my purpose was to merely clean it up and NOT spend the $400+ for the repro...I call it a win.

And as I was looking at it in the corner, I do believe I'm gonna like the solid black centers.

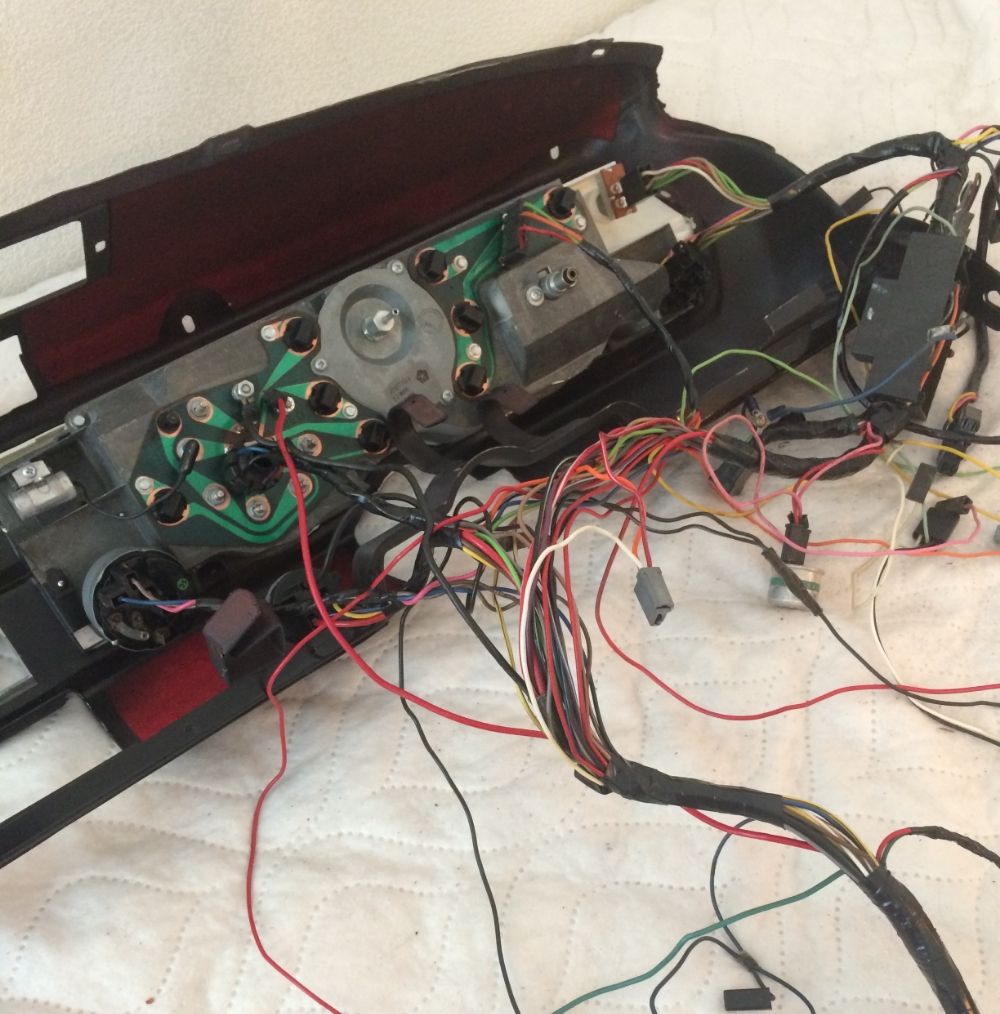

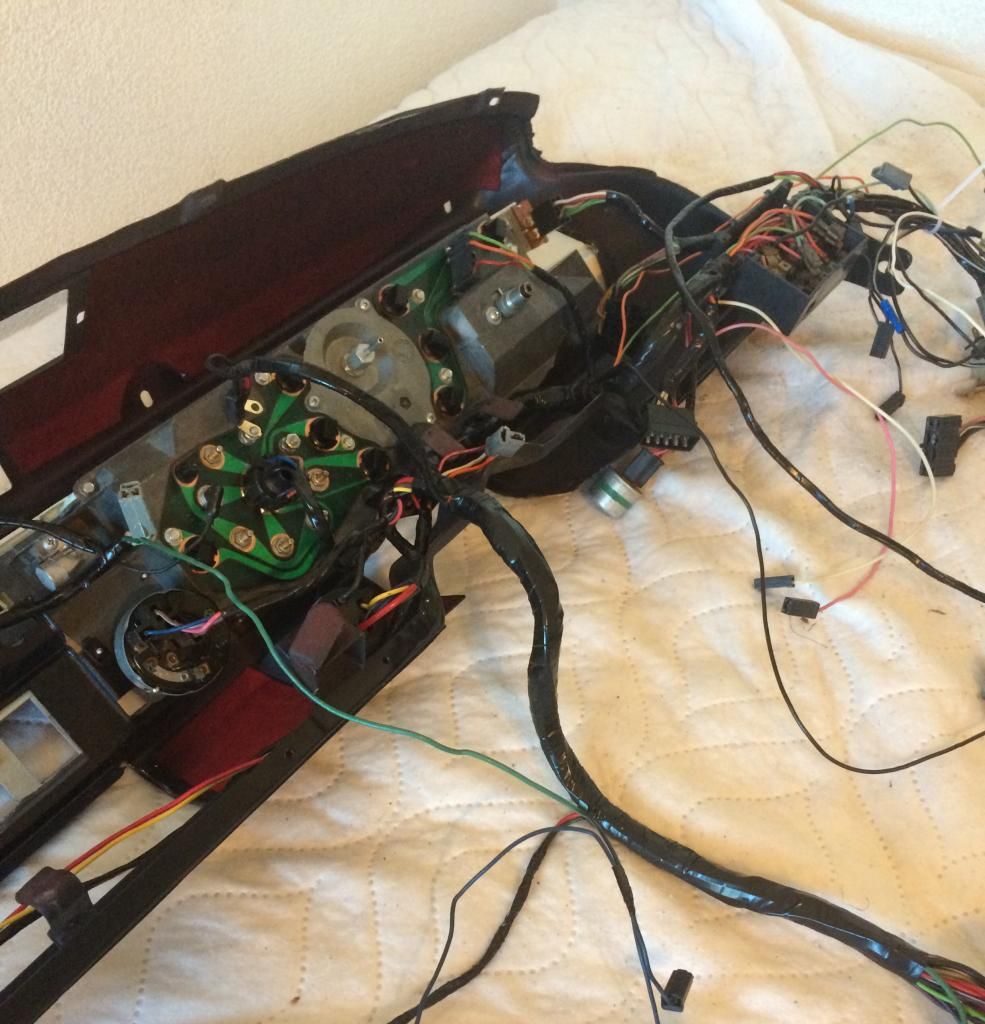

Tomorrow I should be sifting thru my hardware, getting the big parts bolted together, putting the wires in position and taping up the harness. I'd like to be hauling it home like that.

And as I was looking at it in the corner, I do believe I'm gonna like the solid black centers.

Tomorrow I should be sifting thru my hardware, getting the big parts bolted together, putting the wires in position and taping up the harness. I'd like to be hauling it home like that.

I would call it a win as well!!

The centers on a 69 should be black with a white highlight around the circumference .

The centers on a 69 should be black with a white highlight around the circumference .

Rocker'sDuster

MOPAR rookie!

Looks awesome dude!

Definite win...soo much that after seeing yours, I am pretty sure I am going to try and tackle my own and save money!

Definite win...soo much that after seeing yours, I am pretty sure I am going to try and tackle my own and save money!

Hey Rocker - thanks! Yeah, you can spruce up your dash if you know, going into it, what the limitations are for the DIY'er (such as chrome-in-a-can isn't all that chromey) and that your expectations are appropriate. I was wanting mine to be presentable and not all splotchy or flaky. But yeah, time & patience > $450. If I go to a nicer cluster, it will only be after I have the car running 100%.

Tidying up some loose bits. A crack in the plastic that I repaired with JB weld has failed and is a crack, once again. Dremel'd out the old weld, creating a channel, and filled it with fresh JB and a straight section of heavy paper clip wire for reinforcement. JB bonds to metals much better than plastics.

Managed to pop one of my gauge faces off it's brace so I glued it back down with a dab of JB as well.

Identified which screws go where so I'll be ready to reassemble once the bonds are set up.

Haven't done much else today as I actually had to work solid up till 2:30. Just need some peace for the rest of the day.

Now to go clean my helo's windshields.

Managed to pop one of my gauge faces off it's brace so I glued it back down with a dab of JB as well.

Identified which screws go where so I'll be ready to reassemble once the bonds are set up.

Haven't done much else today as I actually had to work solid up till 2:30. Just need some peace for the rest of the day.

Now to go clean my helo's windshields.

I was like, "huh?" That's just a decal. But there is a G-Dec under the bed cover \\ /

/

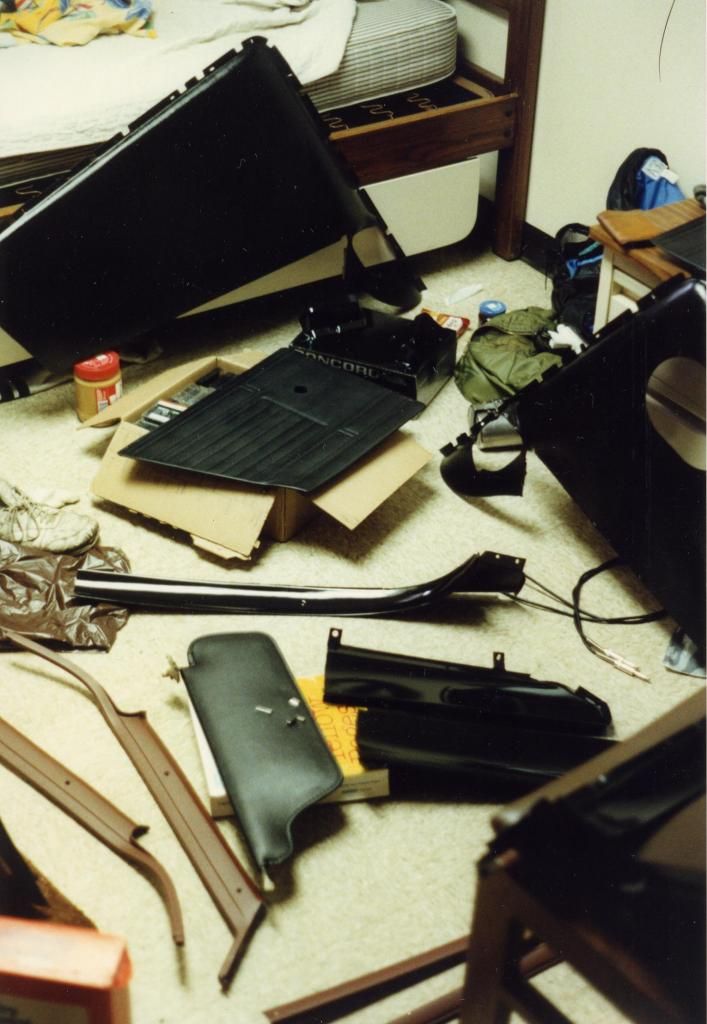

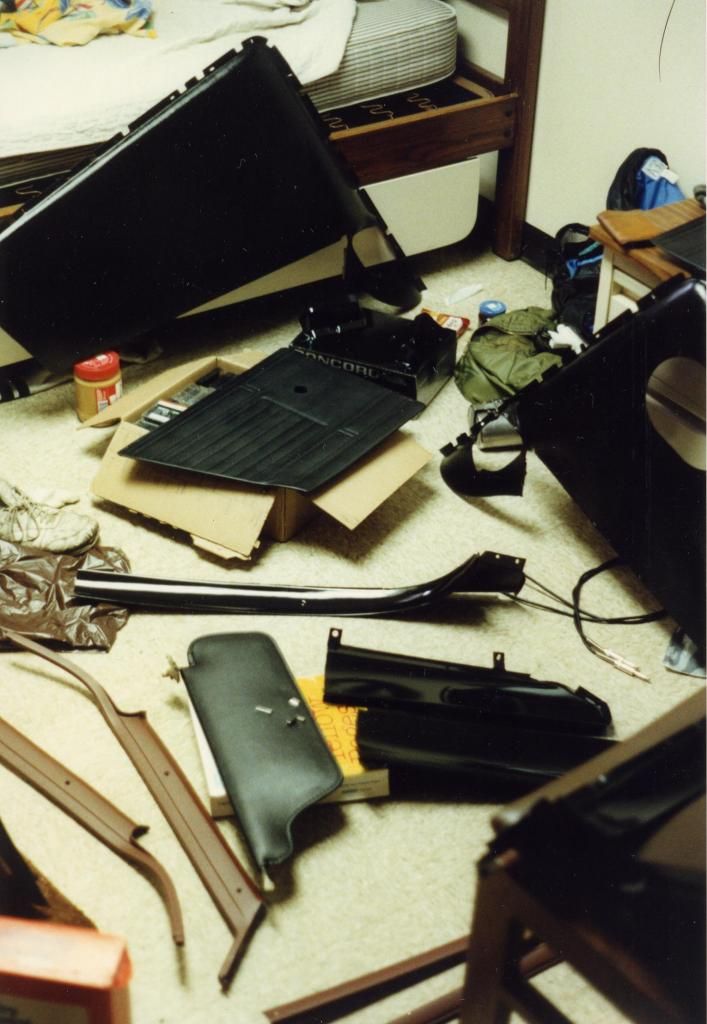

Kicking off Sunday with a little retro fish-****. So there I was with this battered, unloved '69 and an olive green interior which I was also not loving. In the gravel parking lot in front of my awesome, stick-frame, built-in-the-50's Army barracks I pulled out the interior and did a shade-tree color change.

Metal and plastic parts got primed and painted. I used spray cans of vinyl dye for the door panels and visors. My barracks room (seen below) served as my drying booth as it was a tad chilly in the Tacoma area for such things. Tip-toeing around this stuff for two days was no fun at all.

This was 26 years ago. Wow.

Metal and plastic parts got primed and painted. I used spray cans of vinyl dye for the door panels and visors. My barracks room (seen below) served as my drying booth as it was a tad chilly in the Tacoma area for such things. Tip-toeing around this stuff for two days was no fun at all.

This was 26 years ago. Wow.

moparlover

Well-Known Member

Tidying up some loose bits. A crack in the plastic that I repaired with JB weld has failed and is a crack, once again. Dremel'd out the old weld, creating a channel, and filled it with fresh JB and a straight section of heavy paper clip wire for reinforcement. JB bonds to metals much better than plastics.

get some stainless steel screen. i usually cut a piece to fit on the hidden side of a crack/break/whatever and use a wood burner to embed within the plastic.

works better than most of the goop they sell in tubes

Try to imagine how much you would have to pay some one to do all that. Now multiply by 10 and that's your satisfaction factor! Keep it rollin!

I can imagine that. I'll just think, "what would I charge for all this?" lolz

And yes...anytime you're using any sort of epoxy - results are much better when there is a reinforcing medium infused.

Summary for the week (because we had such a light week, I got all my work done already)

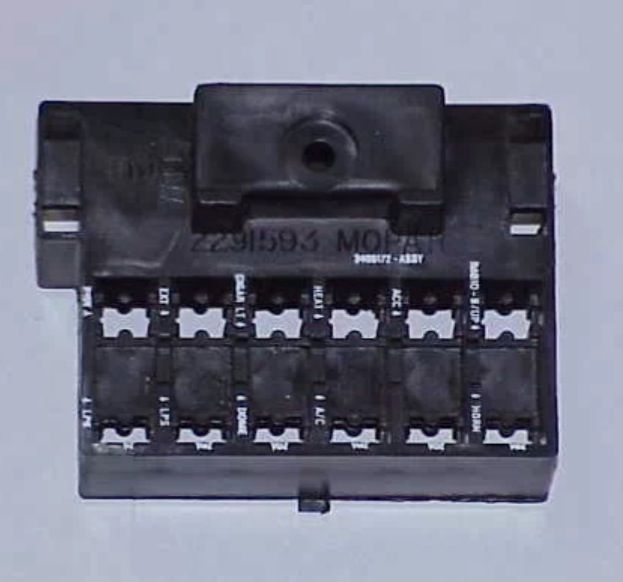

---While I wanted to go home with a singular, completed assembly, there was one piece I forgot to bring that is keeping me from screwing all the big parts together. That long metal strip that goes across the top of the plastic cluster. No big deal. All of the pain is over and reaching the stated goal is only about 10 minutes away - turning a few screws and tightening down the various switches on the panel.

**actually, I have some felt sound dampener to glue to the inside of the frame but that won't take long.

And yes...anytime you're using any sort of epoxy - results are much better when there is a reinforcing medium infused.

Summary for the week (because we had such a light week, I got all my work done already)

---While I wanted to go home with a singular, completed assembly, there was one piece I forgot to bring that is keeping me from screwing all the big parts together. That long metal strip that goes across the top of the plastic cluster. No big deal. All of the pain is over and reaching the stated goal is only about 10 minutes away - turning a few screws and tightening down the various switches on the panel.

**actually, I have some felt sound dampener to glue to the inside of the frame but that won't take long.

SNKEBIT

Spending $$ on Mopars

Gettin' close!!!!!!!!!!!:burnout:

Busy morning here in the office. Finally got some time to glue down a little red felt (noise suppression) on the back of the dash frame. Now it is official: I've worked myself out of work for this shift. Now I let the glue dry and pack everything up in the truck bed for the ride home tomorrow evening.

momoparman

MOISMYHOME

One thing a day baby......lookin good. :cheers:

momoparman

MOISMYHOME

Don't know if you've considered this but installing a dedicated ground wire to the back of the instrument cluster, bonding it via ring terminals to each circuit boards ground screws and then running it back to the chassis or even to the battery negative will give you a low impedance ground path and your will have no issues with any gauges. Keep up the good work.

SNKEBIT

Spending $$ on Mopars

Don't know if you've considered this but installing a dedicated ground wire to the back of the instrument cluster, bonding it via ring terminals to each circuit boards ground screws and then running it back to the chassis or even to the battery negative will give you a low impedance ground path and your will have no issues with any gauges. Keep up the good work.

Very good idea.

-

Similar threads

- Replies

- 9

- Views

- 352

- Replies

- 41

- Views

- 2K