TheCrackHead

Banned

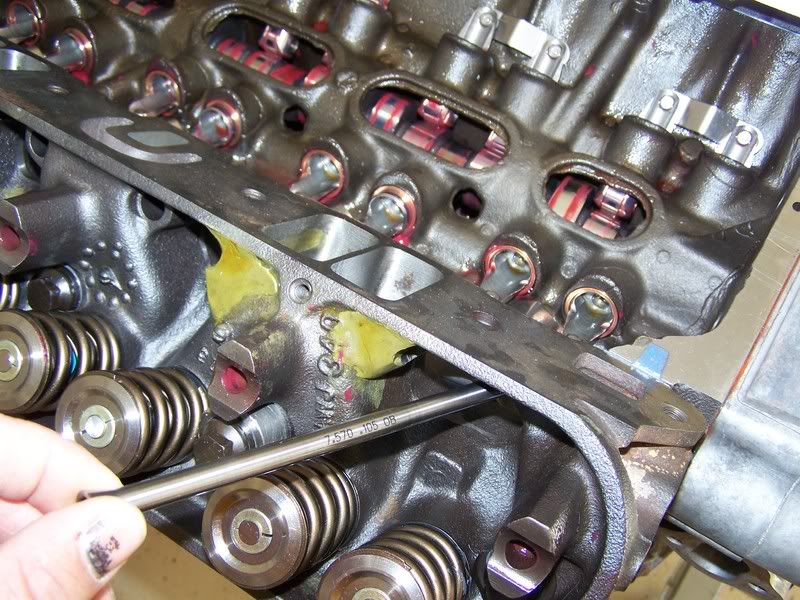

I have a set of J heads that were given to me by a good friend who wanted me to go 'all out' with a port job, the deal was they are free and if I hit water who cares, so all out I went and after that I had them pressure tested, seats installed int/ex, 11/32 bronze guides, spring pads cut for engle doubles, milled, 5 angle valve job.

Pics below are before any machining was done -already had int seats- .

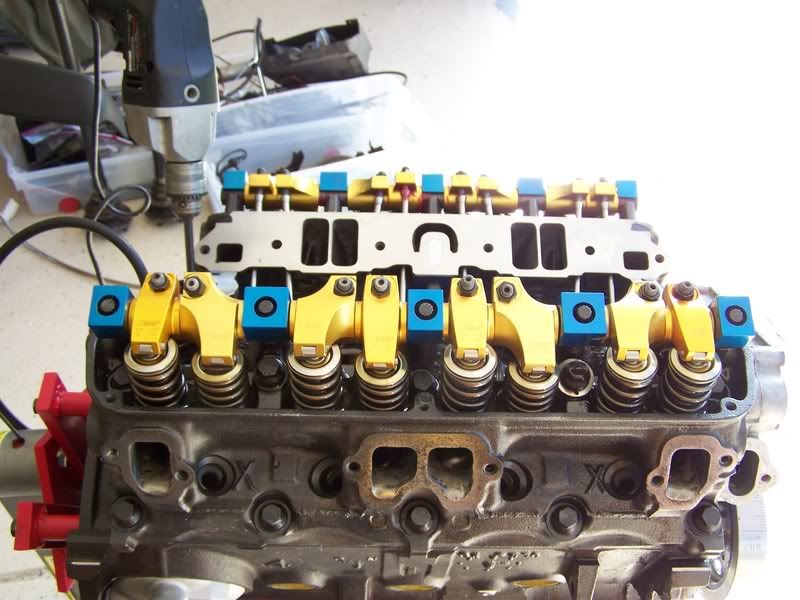

But the real question is having increased the installed height .200 how do I fix the rocker geometry?, is milling the stands and fabbing new ones mandatory?

Pics below are before any machining was done -already had int seats- .

But the real question is having increased the installed height .200 how do I fix the rocker geometry?, is milling the stands and fabbing new ones mandatory?