lgjhn

"The faster you go, the faster you go..."

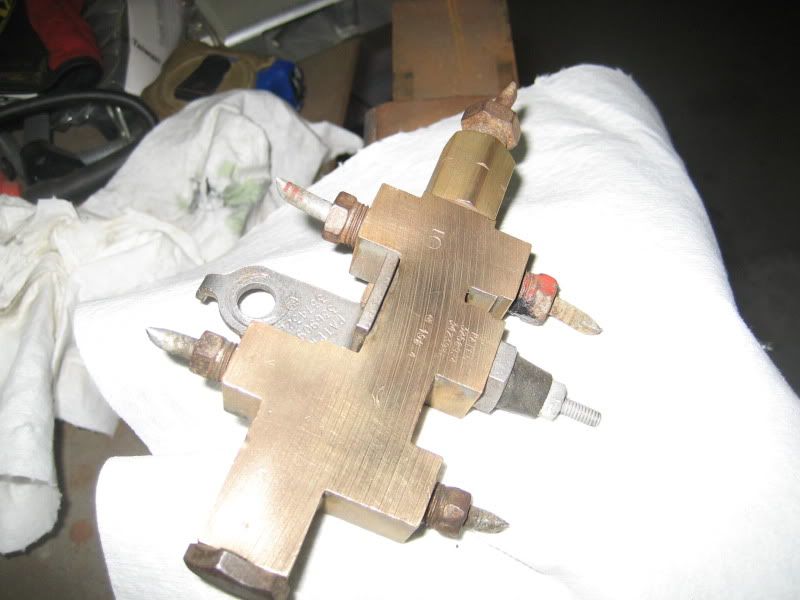

The following is a pictorial of how I cleaned up a proportional valve. This is for informational purposes only and if you elect to do something similar to this, you're on your own and I take no responsibility for your results (I hang around too many lawyers....LOL). This is a typical junk yard score or your 35+ year old valve:

I cut the excess tubing off with a set of side cutters or dykes leaving about an inch or so of the old tubing. I do this for a couple of reasons: 1. It provides a cheap source of good plugs to keep the trash and mud daubers out. 2. It allows me to get a 6-point socket or closed-end wrench over those fittings. You're gonna want that because most of these are in there really tight where even a tubing wrench won't move em. 3. It saves rounding off the fittings that could otherwise be cleaned up and re-used if need be. Here it is fresh from the bead blaster and tubing lines cut as described:

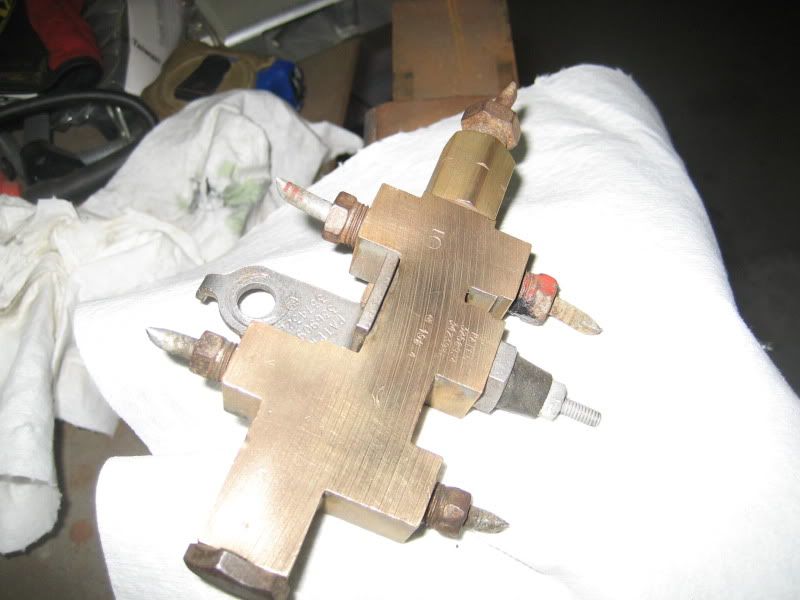

Clamp it in a vice, get the fittings (plugs) out and take a 3/4" wrench to the bottom nut. Be careful because this nut is under spring pressure and has a small metal washer that you do NOT want to loose:

I cut the excess tubing off with a set of side cutters or dykes leaving about an inch or so of the old tubing. I do this for a couple of reasons: 1. It provides a cheap source of good plugs to keep the trash and mud daubers out. 2. It allows me to get a 6-point socket or closed-end wrench over those fittings. You're gonna want that because most of these are in there really tight where even a tubing wrench won't move em. 3. It saves rounding off the fittings that could otherwise be cleaned up and re-used if need be. Here it is fresh from the bead blaster and tubing lines cut as described:

Clamp it in a vice, get the fittings (plugs) out and take a 3/4" wrench to the bottom nut. Be careful because this nut is under spring pressure and has a small metal washer that you do NOT want to loose: