KitCarlson

Well-Known Member

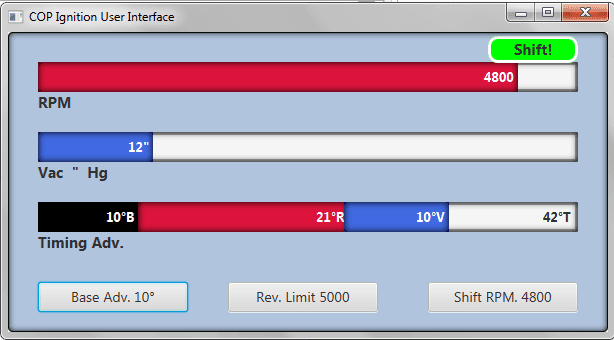

With the temperatures in the 90's and high humidity, I am developing application software for the ignition system. I am working on one screen at a time. The first screen is the real-time display that shows engine RPM, Vacuum, and Ignition Timing.

The timing advance is the typical base timing set at distributor, RPM advance, and Vacuum advance summed together. The base advance can be set with static timing of the distributor, by setting crank position for desired advance, then set distributor so reference tab location aligns with window in optical sensor. A timing light can be used to verify desired timing, I find it is within a degree or two. The base timing is then set and button at lower left can be clicked with mouse buttons to increase or decrease value to match your desired timing. The black section shows 10 degrees in this example. Unless you change the distributor location, once set you are done forever. I will incorporate lock out feature for settings, that may incorporate password or other means to prevent undesired changes.

There will also be rev limit and shift light settings. No pills or dip switch settings for this ignition. The unit stores settings in non-volatile memory.

I have a running simulating example for those who have Java installed. If interested in trying, post and I will see if the zip of the Java can be uploaded for test.

The timing advance is the typical base timing set at distributor, RPM advance, and Vacuum advance summed together. The base advance can be set with static timing of the distributor, by setting crank position for desired advance, then set distributor so reference tab location aligns with window in optical sensor. A timing light can be used to verify desired timing, I find it is within a degree or two. The base timing is then set and button at lower left can be clicked with mouse buttons to increase or decrease value to match your desired timing. The black section shows 10 degrees in this example. Unless you change the distributor location, once set you are done forever. I will incorporate lock out feature for settings, that may incorporate password or other means to prevent undesired changes.

There will also be rev limit and shift light settings. No pills or dip switch settings for this ignition. The unit stores settings in non-volatile memory.

I have a running simulating example for those who have Java installed. If interested in trying, post and I will see if the zip of the Java can be uploaded for test.